Aluminij Pladenj nakup rabljenega (721)

Udine

Udine Stroji za železo in aluminij

CB

Striegistal

Striegistal Tovarna peči za aluminij

Seco/WawickSDBF-24.16.30/600E

Barakfakih

Barakfakih Aluminij Pvc ročni režijski stroj za rezanje nad glavo

PLASTMAK PVC ALÜMİNYUM İŞLEME MAKİNALARISÇ 431

+44 20 806 810 84

Barakfakih

Barakfakih Aluminij Pvc Večkratni srednji register Lapping

PLASTMAK PVC PROCESSING MACHINESSÇ 211 S

Cluj-Napoca

Cluj-Napoca CNC dvo-glava žaga za aluminij

EmmegiTwin Electra Sun TU/6

Odkrijte več rabljenih strojev

Weißenborn/Erzgebirge

Weißenborn/Erzgebirge Krožna žaga za lahke kovine / aluminij

Tronzadoras MGGAA-600 - CNC

Duxford

Duxford Pladenj za QX medij Qiagen

QiagenQX

Gütersloh

Gütersloh žaga za aluminij Elumatec TS 161

ElumatecTS 161

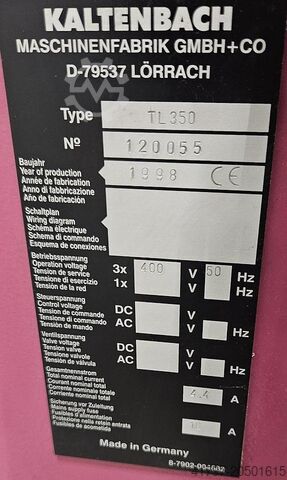

Gütersloh

Gütersloh Žaga za aluminij Kaltenbach TL 350

KaltenbachTL 350

Reichenbach im Vogtland

Reichenbach im Vogtland Krožna žaga za lahke kovine / aluminij

BOMARAL 400 Semi-automatic

Bury St Edmunds

Bury St Edmunds Pladenj za vlaganje

Carsoe / QupaqANYTRAY

Silvi

Silvi 5-osni obdelovalni center za aluminij

MECALMC 302 Geos 5

Cochem-Brauheck

Cochem-Brauheck Krožna žaga za lahke kovine / aluminij

MTIAS-800

Mühltal

Mühltal Krožna žaga za lahke kovine / aluminij / drugo

DiverseDiverse

Forst

Forst Embalaža za pladenj Emcon

EmconTray Packer Power Food

Enschede

Enschede Krožna žaga za lahke kovine / aluminij

OzcelikMETEOR I 500

Ponte Nova

Ponte Nova Kippwanne - nagibni pladenj

Baljer & ZembrodKippwanne - vassoio ribaltabile

Enschede

Enschede Krožna žaga za lahke kovine / aluminij

OZCELIKMETEOR I 420

Wiesbaden

Wiesbaden Krožna žaga za lahke kovine / aluminij

HÄBERLEAL 350/A

Gütersloh

Gütersloh Avtomatska žaga za aluminij Pressta Eisele Profilma 500

Pressta EiseleProfilma 500

Enschede

Enschede Krožna žaga za lahke kovine / aluminij

OZCELIKVEGA II M

Enschede

Enschede Krožna žaga za lahke kovine / aluminij

OZCELIKMETEOR i 420

Enschede

Enschede Krožna žaga za lahke kovine / aluminij

TTMCQCS-400A

Enschede

Enschede Krožna žaga za lahke kovine / aluminij

AYEL-TECHAC-450

Enschede

Enschede Krožna žaga za lahke kovine / aluminij

AYEL-TECHAC-400

Rabljeni Aluminij Pladenj (721)

Zdaj preiščite celoten Machineseeker z več kot 200.000 rabljenimi stroji.Brskajte po najbolj priljubljenih poimenovanjih strojev:

+44 20 806 810 84