Obdelovalni centri z ravno ali mrežasto mizo nakup rabljenega (347)

Razvrsti rezultate

- Najnižja cena Najvišja cena

- Najnovejši oglasi Najstarejši oglasi

- Najkrajša razdalja Največja razdalja

- Najnovejše leto izdelave Najstarejše leto izdelave

- Zadnja posodobitev Najstarejša posodobitev

- Proizvajalci od A do Ž Proizvajalec od Z do A

- Pomembnost

- Najnižja cena

- Cena

- Najvišja cena

- Cena

- Najnovejši oglasi

- Datum objave

- Najstarejši oglasi

- Datum objave

- Najkrajša razdalja

- Razdalja

- Največja razdalja

- Razdalja

- Najnovejše leto izdelave

- Leto izdelave

- Najstarejše leto izdelave

- Leto izdelave

- Zadnja posodobitev

- Nazadnje posodobljeno

- Najstarejša posodobitev

- Nazadnje posodobljeno

- Proizvajalci od A do Ž

- Proizvajalec

- Proizvajalec od Z do A

- Proizvajalec

- Oznaka od A do Ž

- Oznaka

- Oznaka od Z do A

- Oznaka

- Model od A do Ž

- Model

- Model od Z do A

- Model

- Najnižja referenca

- referenca

- Najvišja referenca

- referenca

- Najkrajši obratovalni čas

- Obratovalni čas

- Najdaljši čas obratovanja

- Obratovalni čas

- Pomembnost

- Pomembnost

Stroji za obdelavo lesa CNC obdelovalni centri za les Obdelovalni centri z ravno ali mrežasto mizo

Mali oglas

Stalowa Wola

Stalowa Wola

714 km

Obdelovalni center

SERONExpert+

Klic

Stanje: novo, Leto izdelave: 2026, Control System: Real-time multi-axis interpolator with active trajectory forecasting, LAN communication, EtherCat, 2ms sampling time; optional: RTCP tool center point tracking, correction map

Working Area: X 600–2500 mm, Y 900–6100 mm

Gantry Clearance and Z-axis Range: 100–500 mm

Drive System: Omron servo drives with EtherCat protocol; X, Y axes feature hardened and ground helical racks, accuracy class 6; Z-axis with ball screw, accuracy class 5

Linear Bearings: Bosch Rexroth 25 trapezoidal rails

Traverse Speed: Up to 90 m/min

Acceleration: Up to 1G

Software Resolution: Up to 0.0001 mm

Positioning Accuracy: 0.01 mm

Gantry Drive: Dual-sided master/slave with gantry angle correction

Electrospindles: Up to 18 kW, inverter-driven

Tool Holder: ISO30 or HSK63 ER32

Maximum Spindle Speed: 24,000 rpm (optionally 6,000, 40,000, 50,000)

Construction: Welded, ribbed, stress-relieved, and precision-machined steel frame

Equipment Options:

- Material positioning and correction using camera, laser, or touch probe

- Linear or rotary tool magazine

Ljdpfx Absn Nwifebsrg

- Tool cooling with mist or chilled air

- 3D scanner (laser or touch)

- Positioning bases

- Additional angular/rotary axes

- Drilling and angular aggregates

- Active oscillating, circular, drag knife, creasing tool, marker

- Pneumatic clamping fixtures

- Chip extraction system

Table Type: T-slot table - aluminum profiles, solid aluminum, solid steel; vacuum; hybrid; pneumatic clamps

#plotter #CNC #millingrouter #machiningcenter #3axis #4axis #5axis #3D #3Dprint

#MDF #HPL #Plywood #chipboard #steel #aluminum

Mali oglas

Stalowa Wola

Stalowa Wola

714 km

Obdelovalni center

SeronPRO

Klic

Stanje: novo, Leto izdelave: 2026, Technical Data:

Control System: Multi-axis real-time interpolator with active trajectory prediction, LAN and EtherCat communication, 2ms sampling time, optional RTCP tool tip tracking, compensation map.

Working Area: X 600-3000 mm, Y 900-12000 mm

Gantry Clearance and Z-axis Stroke: 100-1000 mm

Drive System: Omron servo drives with EtherCat protocol; X, Y axes—hardened and ground helical racks, accuracy class 6; Z axis—ball screw, accuracy class 5

Linear Bearings: Trapezoidal rails, Bosch Rexroth 25

Traverse Speed: Up to 120 m/min

Acceleration: Up to 1G

Software Resolution: up to 0.0001 mm

Positioning Accuracy: 0.01 mm

Gantry Drive: Dual-sided master/slave with gantry angle correction

Electrospindles: up to 36 kW, inverter driven

Lredon Hq Huepfx Abbjg

Tool Taper: ISO30 or HSK63 ER32

Maximum Electrospindle Speed: 24,000 rpm (optionally 6,000, 40,000, or 50,000 rpm)

Construction: Welded, ribbed, stress-relieved steel, precision machined

Equipment Options:

- Material positioning and correction using camera, laser, or touch probe

- Linear or turret tool magazine

- Tool cooling with mist or chilled air

- 3D laser or touch scanner

- Positioning stops

- Additional rotary/tilting axes

- Drilling aggregates, angular heads

- Active oscillating, rotary, drag, crease, or pen tools

- Pneumatic clamping systems

- Chip extraction system

- Integration with industrial robots

Table Type: T-slot—aluminium profiles, solid aluminium, solid steel; vacuum table; hybrid; pneumatic clamps

#ploter #CNC #millingrouter #machiningcenter #3axis #4axis #5axis #3D #3Dprint

#MDF #HPL #Plywood #chipboard #steel #aluminium #aluminum

#brass #stainlesssteel #castiron #polypropylene #polycarbonate #acrylic #fermacell #BLUM

Mali oglas

Stalowa Wola

Stalowa Wola

714 km

Obdelovalni center

SERON5 Axis ProG+

Klic

Stanje: novo, Leto izdelave: 2026, Technical Data

Control System: Multi-axis real-time interpolator with active trajectory forecasting, LAN and EtherCat communication, sampling time below 1 ms, RTCP, remote service access.

Working Area: X: 2000–4700 mm; Y: 3000–30000 mm

Z-Axis Clearance: up to 3000 mm

Lodpfx Abowhxcgoborg

Drive System: Servo drives with EtherCat protocol, X, Y, Z axes equipped with hardened, ground helical racks, accuracy grade 6

Linear Bearings: Trapezoidal rails, Y-axis quadruple guideway size 35, X and Z-axis triple guideway size 35

Traverse Speed: X, Y up to 25 m/min; C, A up to 6000°/min

Program Resolution: 0.0005 mm

Positioning Accuracy: 0.01 mm

Gantry Drive: Dual-side master/slave system with gantry angle correction

Electrospindles: up to 50 kW

Electrospindle Inverter: Yes

Maximum Electrospindle Speed: 24,000 rpm (optionally 6,000 – 40,000 rpm)

Construction: Welded, stress-relieved, precision-machined steel gantry structure

Table Type: Modular T-slot (steel, aluminium), separated from the main frame

Available Optional Equipment:

- 3D printhead

- Tool cooling system

- Tool magazine: linear or mobile, turret, chain

- Saw units

- Laser scanner

- Wireless probe

- Machining area separators

- Compensation map

- Roller roof

- Vacuum table

- Extraction shoe for 5-axis heads

- Specialized CAD/CAM software

3D pellet printers can process a variety of plastics, such as PLA, ABS, PETG, polyamides, or polypropylene.

#ploter #CNC #router #millingrouter #machiningcenter #3axis #4axis #5axis #3D #3Dprint

#MDF #HPL #plywood #chipboard #steel #aluminium #aluminum

#brass #stainlesssteel #castiron #polypropylene #polycarbonate #acrylic #fermacell

Izvedite več zdaj

+44 20 806 810 84

+44 20 806 810 84

Objavite oglas zdaj

*na oglas/mesec

Mali oglas

Stalowa Wola

Stalowa Wola

714 km

CNC za varjenje kondenzatorjev

SERONCNC do zgrzewania kondensatorowego 1510

Klic

Stanje: novo, Leto izdelave: 2026, potovalna razdalja osi X: 1.500 mm, pomik osi Y: 1.000 mm, Technical Data:

X, Y Axis Travel Range: from 600 x 900 mm up to 2100 x 2100 mm

Z Axis Travel: up to 500 mm

Control System: Multi-axis real-time interpolator with active trajectory prediction, LAN and EtherCat communication, 2 ms sampling time, optional: RTCP tool-tip tracking, correction map

Drive System: Servo drives with EtherCat protocol;

X, Y axes: hardened, ground helical racks, accuracy class 6; Z axis: ball screw, accuracy class 5

Linear Guides: Trapezoidal rails

Travel Speed: Up to 90 m/min

Software Resolution: up to 0.0001 mm

Positioning Accuracy: 0.01 mm

Gantry Drive: Dual-sided master/slave with gantry angle correction

Automatic Head: SK type

Material: Steel, Stainless Steel, Aluminium, Brass

Welding Range: Ø 3 - M 8

Stud Welding Range: M 3 x 6 - M 8 x 40; 50 to 100 Volt, fully adjustable, accuracy ± 1 Volt

Ball Bearing

Min. Tolerance / 490 Ws at 99 V

Stroke: Pneumatic, 50 mm

Lsdpfx Aev T Uy Tsbborg

Weight: 1.5 KG (without cable)

Option: Multi-head CNC Capacitor Discharge Welding

Mali oglas

Stalowa Wola

Stalowa Wola

714 km

CNC obdelovalni center

SERONProNEST

Klic

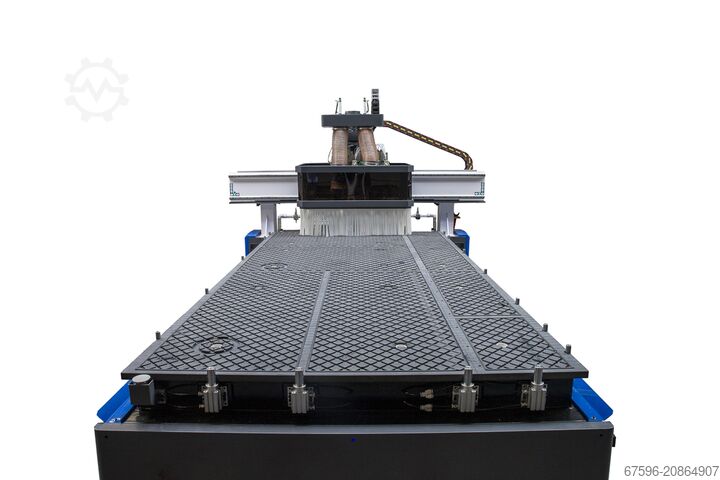

Stanje: novo, Leto izdelave: 2026, Technical Specifications:

Control System: Multi-axis real-time interpolation controller with active trajectory prediction, LAN and EtherCat communication, sampling time below 2 ms, correction map, RTCP, and remote service access.

Working Area: 2100 x 3100 mm (optionally 2100 x 4100 mm)

Z-axis Clearance: 100 – 300 mm

Drive System: Servo drives with EtherCat protocol; X and Y axes equipped with hardened, ground helical racks (accuracy class 6); Z axis ball screw (accuracy class 5)

Linear Guides: Trapezoidal rails

Travel Speed: Up to 80 m/min

Software Resolution: 0.0001 mm

Positioning Accuracy: 0.01 mm

Gantry Drive: Dual-sided master/slave with gantry angle correction

Electrospindles: 8 kW up to 36 kW, inverter controlled

Tool Holder: ISO30 or HSK63 ER32

Maximum Electrospindle Speed: 24,000 rpm

Construction: Welded steel, ribbed, stress-relieved, precision machined

Table Type: Vacuum table

Optional Equipment:

- Material positioning and correction with camera, laser, or probe

- Revolver-type tool magazine

- Tool cooling using oil mist or refrigerated air

- 3D scanner (laser or tactile)

- Positioning stops

- Drilling and angular aggregates

- Active oscillating, rotary, drag, creasing, or plotting knives

Lrodpfsu U Hnaox Abbjg

- Electric or pneumatic drive

- Chip extraction installation

- Pneumatic zones

- Printer, barcode reader

- CAD/CAM software for furniture, cabinet, and front design

- Automatic central lubrication system

#plotter #CNC #millingrouter #machiningcenter #3axis #4axis #5axis #3D #3Dprint

#MDF #HPL #Plywood #Particleboard #Chipboard #steel #aluminum

#brass #stainlesssteel #castiron #polypropylene #polycarbonate #acrylic #fermacell #BLUM;

Mali oglas

Almelo

Almelo

922 km

Obdelovalni center

CNC-ROUTER DMA-BudgeCraftNesting Professional

Klic

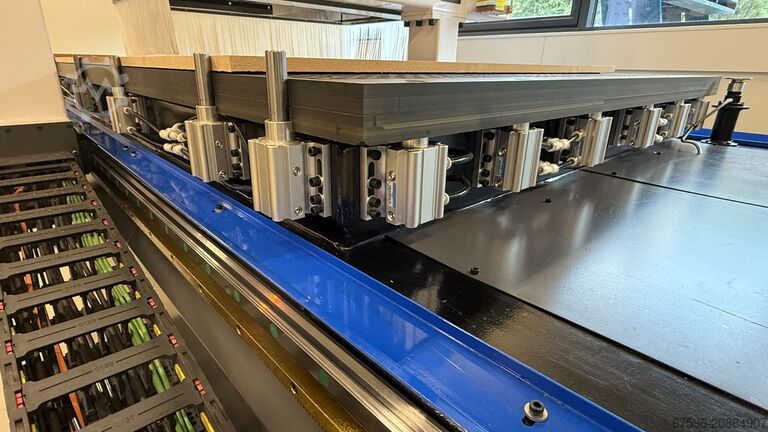

Stanje: pripravljen za uporabo (rabljen), Leto izdelave: 2026, Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 2.600 mm, pomik osi Y: 1.300 mm, pomik po osi Z: 200 mm, hitro pomikanje X-os: 50 m/min, hitri pomik os Y: 50 m/min, hitri pomik na osi Z: 15 m/min, Oprema: dokumentacija / priročnik, transportni trak za ostružke, vrtilna hitrost brezstopenjsko nastavljiva, - BudgeCraft CNC MILLING MACHINE

- Best Price-Quality CNC

- CNC Milling Machine: Wood, Plastic & Aluminium Processing

- High Precision (0.01mm) Milling

- No Annual License Fees

Descriptions:

The most complete CNC machine for wood, plastic, and aluminium. Fully servo-driven for the most complex operations. Starting from €34,500.

- Benefit from fixed price CadCam software and starter kit.

- Assembled in the Netherlands according to the strictest CE standards.

- Powerful 9kW ATC spindle and speeds up to 50m/min.

- Equipped with automatic tool change magazine for up to 16 tools.

- From standard routing to complex projects

- BudgeCraft offers the highest precision and lowest purchase price for professionals.

Highlight extensions:

* No hidden license fees

* CadCam Professional; import BMP, JPG, TIF, GIF, PNG image vector files

* Formats: Adobe Illustrator, DXF (AutoCAD), EPS, PLT, TXT

* 9kW ATC air-cooled spindle

* Ready for immediate use

CNC ROUTER:

Precision CNC ROUTER specifications: View the technical details of our 0.01mm accuracy machine.

Working Areas & Options: From 1300x2600 - 1600x3200 - 2100x3200mm.

CE Safety: Why our machines are the safest choice for your workshop. Complies with the New Machinery Regulations 2026.

Full technical specification overview available at Danmar Machines Bv website:

Working range X-axis: 2600, 3200mm

Lrjdpfx Asx Sx Rfjbbsg

Working range Y-axis: 1300-1600-2100mm

Z-axis stroke: 200mm

Gantry construction: Yes, servo motors

Milling motor: 9kw servo motor (ATC spindle)

Speed: 1,000-24,000 rpm

Travel speed X-axis: 50m/min

Travel speed Y-axis: 50m/min

Travel speed Z-axis: 15m/min

Tool holder: ISO30-ER32-ER40

Software: Pegasus PWoodMilling

Vacuum pump: included

Contact us for more information.

Mali oglas

Leipzig

Leipzig

609 km

Obdelovalni center

FORMAT-4profit H10 22.43

Klic

Stanje: rabljeno, Leto izdelave: 2017, obratovalne ure: 1.800 h, No. 3131

CNC Machining Centre FORMAT-4 profit H10 22.43

Used, year of manufacture 2017

Operating hours approx. 1800 h

Package consisting of CNC Machining Centre FORMAT-4 profit H10 22.43, Feeding Unit FORMAT-4 L-Motion, and Extraction System FELDER RL 300

CNC Machining Centre FORMAT-4 profit H10 22.43 Technical Data:

Phenolic resin matrix table system

Grid table with two stop rows

Automatic central lubrication

HARDWARE control computer

Mobile control console

Handheld terminal for remote axis control

Two vacuum pumps, rated output 2 x 250 m3/h

Tool changer with 10 tools

Tool changer on the left in the machine frame: 8 tool positions for HSK

Milling spindle 12 kW (S6) HSK F63, 24,000 rpm

Central extraction via combined connections (D=250mm)

Software: Woodflash German (H20/H08/H10/H50)

Axis travel H10 22.43: X= 5230 mm / Y= 2560 mm / Z= 280 mm

Working area: X= 4300 mm / Y= 2160 mm / Z= 105 mm

Axis positioning speed: X= 100 m/min / Y= 100 m/min / Z= 30 m/min

Feeding Unit FORMAT-4 L-Motion Technical Data:

Year of manufacture 2017

2-axis version with 4 storage positions for loading an H10 with lifting table

CNC loading

Gentle transport

Fully automatic panel handling

Workpiece dimensions: Length 2000-4200 mm / Width 600-2100 mm / Thickness from 8 mm / Panel weight 200 kg

Density: Chipboard 650 kg/m3 / Raw MDF 750 kg/m3

Stack height 1800 mm

Extraction System FELDER RL 300 Technical Data:

Year of manufacture 2023

Nominal volume flow 6000 m3/h, H3 GS dust-tested, JET cleaning

Compressed air connection 3/4 inch

Connection pressure 7 - 12 bar at 40 NL/min

Operating pressure in the unit 6 bar

Chip container volume 500 l

Fire extinguishing system with powder extinguisher, 12 kg dry powder extinguisher

Lodsrrh T Ajpfx Abborg

Sale on behalf of customer, ex location Leipzig, without dismantling, transport, or installation

Errors in description and price reserved

Dismantling and loading by us is available as an option

To avoid misunderstandings, on-site inspection by appointment is possible and recommended

Sale takes place in as-is condition

Technical data, condition description, year of manufacture, and scope of delivery according to manufacturer’s brochure or previous owner, without guarantee

Subject to prior sale

For used machines, any warranty is excluded; sold as seen

Pictures and videos are examples and do not represent the actual scope of delivery

Payment terms: Prices plus statutory VAT, payment prior to collection or shipping

Delivery terms: ex location

Mali oglas

Trzcianka

Trzcianka

774 km

Obdelovalni center

CNC FelderProfit H20

Klic

Stanje: rabljeno, Leto izdelave: 2011, Naprodaj CNC obdelovalni center profit H20 Format-4 Felder - 2011.

Stroj je v stalni uporabi, trenutno je mogoče preveriti njegovo delovanje med delom!

3-osni center s pripravljenostjo za 4. os.

Obdelovalno območje 1250x3150 mm, višina Z=100 mm, možnost dela na dveh delovnih površinah.

Leta 2024 je bil obnovljen elektro vreteno.

Vsa popravila in vzdrževanja so bila izvedena s strani usposobljenega servisa.

Zagotovimo nakladanje.

Prevoz na strani kupca – tovorno vozilo z dolžino kesona 7-8 m.

Pogoji za priključitev stroja:

-Električni kabel 5x4mm2 s priključkom, ki ustreza vtičnicam v delavnici

-Električna zaščita (najmanj) 32A industrijska, izbrana glede na moč motorjev. Splošno pravilo: nazivni tok na stroju (tablica) + 40 %

-Pnevmatski priključek z notranjim premerom min. 12 mm

-Kompresor z zmogljivostjo vsaj 100 l/min

-Odvodna napeljava

Izdajamo račun z DDV

Naveden znesek je neto.

Za vprašanja nas prosimo kontaktirajte po telefonu ali e-pošti.

Lrodpsxg Ehdefx Abbsg

Mali oglas

Almelo

Almelo

922 km

Obdelovalni center

DMA MACHINERY-ROUTERSEXPRESS1326-ATC

Klic

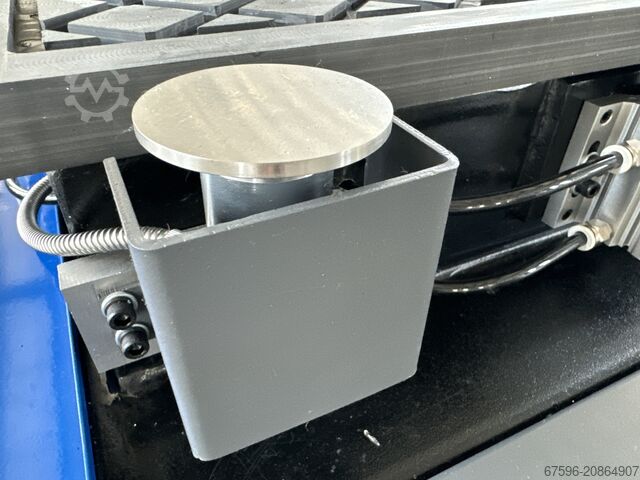

Stanje: novo, Leto izdelave: 2026, Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 2.600 mm, pomik osi Y: 1.300 mm, pomik po osi Z: 200 mm, hitro pomikanje X-os: 40 m/min, hitri pomik os Y: 40 m/min, hitri pomik na osi Z: 15 m/min, višina obdelovanca (maks.): 350 mm, skupna dolžina: 3.500 mm, skupna širina: 2.100 mm, vrtljajska hitrost (min.): 1.000 obr/min, največja hitrost vrtenja: 24.000 obr/min, skupna masa: 2.460 kg, vhodna napetost: 400 V, Oprema: dokumentacija / priročnik, transportni trak za ostružke, vrtilna hitrost brezstopenjsko nastavljiva, CNC Nesting Machine

EXPRESS-ROUTER CNC router is the new custom machining center for those who demand precision and reliability.

Lrsdpfx Abox R D Rnobsg

Designed and assembled in the Netherlands according to the strictest European standards.

This machine is engineered for small and medium-sized enterprises.

Featuring a robust welded steel frame, servo drive system, automatic tool changer, and intelligent software integration, it is the ideal solution for everything from cabinet making to complex 3D relief machining.

Why DMA MACHINERY

- Price & Quality

- Minimal floor space required

- Complies with the latest European Machinery Regulation (EU)2023/1230

- CNC Gantry Router

- Capable of processing: wood, plastic, aluminum, acrylic, foam, composites, etc.

- Unlimited possibilities

- No license fees

- CadCam software Pegasuds (see videos)

- 1 year online helpdesk support

CNC Machines: Honestly priced, for craftsmen who can do it themselves.

Pay for steel, not for service. Our CNCs are for the resourceful, independent entrepreneur.

Focus on functionality: Your machine, your control, our lowest price.

Choose self-assembly and save tens of thousands of euros on your new CNC machine.

The power of CNC without the overhead costs. For professionals with technical expertise.

Mali oglas

Almelo

Almelo

922 km

Obdelovalni center

DMA Machinery CNC-ROUTERSExpress-1326 ATC ( COMPACT )

Klic

Stanje: novo, Leto izdelave: 2026, Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 2.600 mm, pomik osi Y: 1.300 mm, pomik po osi Z: 200 mm, hitro pomikanje X-os: 60 m/min, hitri pomik os Y: 60 m/min, hitri pomik na osi Z: 20 m/min, proizvajalec krmilnikov: syntec, dolžina obdelovanca (maks.): 6.000 mm, širina obdelovanca (maks.): 2.100 mm, višina obdelovanca (maks.): 350 mm, skupna višina: 2.200 mm, skupna dolžina: 4.200 mm, skupna širina: 2.100 mm, obremenitev mize: 1.500 kg, vrtljajska hitrost (min.): 1.000 obr/min, največja hitrost vrtenja: 24.000 obr/min, skupna masa: 2.800 kg, nosilec vretena: MK 3, število mest v zalogovniku orodij: 10, vhodna napetost: 400 V, vrsta vhodnega toka: trifazni, Oprema: dokumentacija / priročnik, vrtilna hitrost brezstopenjsko nastavljiva, Cost savings for the end customer: €80,000 instead of €40,000

DMA supplies high-quality CNC machines at unbeatable prices, as costly service contracts and on-site installations are not required. Perfect for professionals who want to retain full control.

Included in the purchase price:

- "SYNTEC" CNC controller

- CNC nesting/milling CAD/CAM

- PEGASUS Professional CAD/CAM including online training/helpdesk

- Starter kit with cutting and drilling tools for CNC sheet metal processing

• Spare parts supply: In the event of a defect within 12 months, spare parts will be shipped free of charge after diagnosis (photo/video). • Labor costs not included: You can replace the part yourself or hire an external service provider.

• Low-maintenance designs.

• Digital setup: via app or TeamViewer, direct online service. This eliminates the need for technician visits, saving time and money.

• Online service: 24/7 support.

Digital support as an alternative

• Video tutorials: Clips for calibration or part replacement.

• Exploded diagrams: Components immediately identifiable.

Functionality in focus: Your machine, your management, our best price.

Usable working area: 3200 x 1600 mm (standard sizes available).

Z-axis: 200 mm.

Automatic tool changer with 9-kW milling spindle.

Up to 26 spindle positions.

Row drilling unit optional. Slot milling unit optional.

CadCam nesting software.

Pressure rollers (for uneven material) optional.

Becker VTLF2.250 vacuum pump.

All axes servo-driven.

Lsdpfxjx Rz Auj Abbjrg

Heavy-Duty CNC Milling Machine

Type: "NESTING"

Working area: 1300 x 2600 mm (standard sizes available)

Z-axis: 200 mm

ATC 9 kW milling spindle

Drilling unit optional

Slot milling unit optional

CadCam nesting software

Pressure rollers (for uneven material) optional

Becker VTLF2.250 vacuum pump

All axes servo-driven

Mali oglas

Almelo

Almelo

922 km

Obdelovalni center

CNC nesting Machine CE-DUTCH normeringCNC Best solution 3022

Klic

Stanje: novo, Leto izdelave: 2026, Funkcionalnost: popolnoma funkcionalen, Cost savings for the end user €80,000 vs. €40,000

DMA supplies high-quality CNC machines at rock-bottom prices by foregoing expensive service contracts and installation visits. Ideal for professionals who prefer to stay in control themselves.

The purchase price includes:

- CNC controller "SYNTEC"

- CNC Nesting/Milling CadCam

- PEGASUS Professional CadCam including online training/helpdesk

- Starter kit of cutting and drilling tools suitable for sheet metal processing CNC machining centers.

• Parts supply: In the event of a defect within 12 months, replacement parts will be shipped free of charge after diagnosis (photo/video).

• Labour not included: Replacement of the part is performed by you or arranged by you.

• Low-maintenance design

Ledpfx Absxx Uc Ujbjrg

• Digital preparation: app- or TeamViewer-based direct online service, making technician site visits unnecessary—saving both time and costs.

• Service Online: 24/7

Digital Support as Alternative

• Video tutorials: clips on calibrating or replacing parts

• Exploded view diagrams: immediately identify the relevant component

Focus on functionality: Your machine, your management, our lowest price.

You can call or WhatsApp us for more information and/or to schedule an appointment.

WhatsApp:

Mali oglas

Chorvátsky Grob

Chorvátsky Grob

286 km

Obdelovalni center

CNC 2530S VariableCNC 2530S Variable

Klic

Stanje: skoraj kot novo (rabljeno), Leto izdelave: 2020, Funkcionalnost: popolnoma funkcionalen, CUT 2530S - Variabilný CNC stroj

EPS rezací stroj so 4 nezávisle pohyblivými osami a variabilným pracovným stolom.

Ljdpfx Abewfdm Eebjrg

Mali oglas

Włoszczowa

Włoszczowa

638 km

Obdelovalni center

BIESSE-UNITEAMUnica

Klic

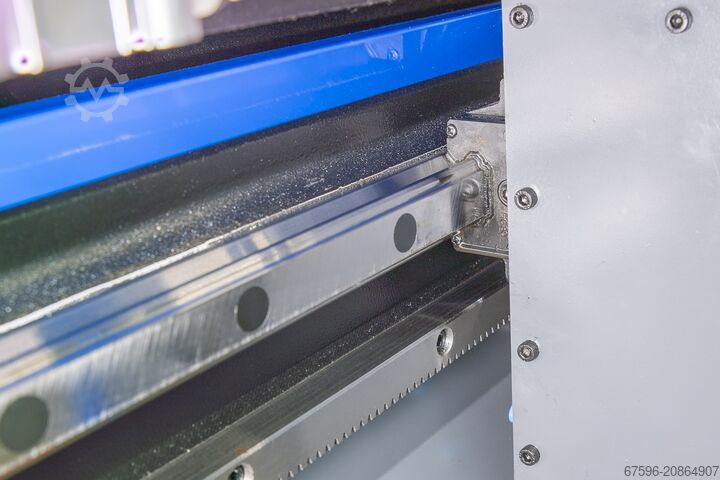

Stanje: zelo dobro (rabljeno), Leto izdelave: 2003, Naprodaj CNC Unica, leto izdelave 2003, z raster mizo, znamka Uniteam, ki spada pod Biesse.

CNC obdelovalni center Biesse-Uniteam Unica, leto izdelave 2003, z raster mizo, idealen za rezkanje lesa, MDF, plošč, pohištvenih front, nosilcev ipd. Poleg vakumskega raster stola so vključene tudi pnevmatske vpenjalne sponke.

Max. delovno območje (X-Y-Z) mm: 3440 x 1300 x 200

Moč vretena: 9 kW

Dimenzije stroja: 5000 x 2350 x 2200 mm

Ledpfxowk Ekco Abborg

Teža: 4000 kg

Mali oglas

Bad Sooden-Allendorf

Bad Sooden-Allendorf

677 km

Obdelovalni center

BIESSERover 30 S2

Klic

Stanje: nepreverjeno (rabljeno), Leto izdelave: 1999, Funkcionalnost: nepreverjeno, 24 vertikalnih vreten, 10 horizontalnih vreten, 7-pozicijski menjalnik orodij, 8 vakuumskih delovnih miz z digitalnim prikazom položaja, zamenljiv kotni menjalnik. Uporabna dolžina delovne površine: 3200 mm, širina delovne površine: 925 mm.

Lrjdpfx Abex Iulwebsg

Mali oglas

Pszczyna

Pszczyna

517 km

Obdelovalni center

KimlaLF 1020 Powercut 2 kW

Klic

Stanje: rabljeno, Leto izdelave: 2022, obratovalne ure: 814 h, Funkcionalnost: popolnoma funkcionalen, nazivna (navidezna) moč: 2 kVA, Kimla LF 1020 Powercut 2 kW Fiber Laser – Precision and Efficiency for Your Production

The Kimla LF 1020 Powercut fiber laser cutter, featuring a 2 kW fiber resonator, is an advanced technological solution designed for companies seeking maximum performance, precision, and reliability in metal processing. As a product from a renowned Polish manufacturer, this machine combines innovative engineering with robust build quality, offering a competitive edge in a fast-paced market.

The LF 1020 model is optimized for processing sheet metal in standard dimensions, offering a working area of 1000 x 2000 mm—making it a versatile tool for a wide range of applications, from single-piece to series production.

Key Features and Advantages:

• Dynamic Linear Drives: Unlike conventional drives, Kimla's proprietary linear drives deliver extreme acceleration and positioning speeds. This significantly shortens cutting times for complex shapes and boosts overall machine productivity.

• 2 kW Fiber Source Power: The 2000 W fiber resonator strikes an ideal balance between cutting speed and capabilities. It enables efficient processing of mild steel, stainless steel, aluminium, and non-ferrous metals such as copper or brass (upon consultation with the manufacturer), while maintaining excellent edge quality.

• High Energy Efficiency: Fiber laser technology offers significantly higher energy efficiency compared to CO₂ lasers, resulting in lower electricity bills and reduced environmental impact.

• Monolithic, Rigid Construction: The machine body, manufactured as a single, rigid component, ensures exceptional stability and resistance to vibrations even at maximum processing speeds. This directly translates into top-tier cutting precision and repeatability.

• Intuitive Software: The integrated Kimla control system and software are user-friendly, enabling fast project preparation (CAD/CAM) and complete control over the cutting process.

• Low Operating Costs: With no optical components requiring frequent maintenance (unlike mirrors in CO₂ lasers) and the fiber resonator's long lifespan, maintenance costs and service downtimes are kept to a minimum.

Technical Specifications:

Model: Kimla LF 1020 Powercut

Laser resonator power: 2 kW (2000 W)

Resonator type: Fiber

X/Y working area: 1000 mm x 2020 mm

Lsdpfew Izayex Abbsrg

Axis drives: Magnetic linear

Control system: Integrated Kimla system

Applications:

The Kimla LF 1020 laser is the perfect tool for:

• Metalworking and sheet metal fabrication companies

• Manufacturers of machines, equipment, and steel structures

• Automotive sector

• Advertising industry (visual elements, 3D letters)

• Companies producing metal furniture and interior fittings

Mali oglas

Wijchen

Wijchen

922 km

CNC horizontalni obdelovalni centri SCM Record 110 AL TVN Prisma 2006

SCMRecord 110 AL TVN Prisma

Klic

Stanje: rabljeno, Leto izdelave: 2006, Net weight: 4,000 kg

Price: On request

What are Presale Items at Second Owner?

Presale items are machines that we sell in their current condition ("as-is"). We have purchased these machines solely based on photos and sell them with the information provided in the listing. Unfortunately, we do not have additional details such as exact dimensions or machine specifications. In addition, these machines are often not yet in stock and have not been inspected by us.

These machines are offered at attractive prices, meaning the prices are lower than usual, but the risk is fully borne by the buyer. Please review the information in the listing carefully before making a purchase.

If you have any questions, feel free to contact us!

- Machine available from: 2026-05-25

- Year of manufacture: 2006

- Documentation available: No

- CE marking present: Yes

- CE certificate available: No

- Number of milling spindles [pcs]: 1

Lsdex Hfikspfx Abborg

- └ Milling spindle 1:

- Number of controlled axes [pcs]: 5

- Min. spindle speed [rpm]: 600

- Max. spindle speed [rpm]: 20,000

- Main motor power [kW]: 11

- C-axis present: Yes

- Type of router table: Beam table

- Tool clamping system: HSK-F63

- Drilling unit present: Yes

- └ Horizontal drilling spindles [pcs]: 6

- └ Vertical drilling spindles [pcs]: 12

- Saw unit present: Yes

- Tool changer positions [pcs]: 16

- System/software: Xilog Plus

- Safety feature: Safety mat

- Vacuum pump present: Yes

- └ Main motor power [kW]: 5.5

- └ Capacity [m³/h]: 250

- CNC options: Waste conveyor, manual control

- Table length [mm]: 3,050

- Table width [mm]: 1,240

- Z-axis working range [mm]: 200

- X-axis max. traverse [mm]: 3,500

- Y-axis max. traverse [mm]: 1,815

- Z-axis max. stroke [mm]: 440

- Transport weight [kg]: 4,000 kg

- Transport packages [pcs]: 1

Financial Information

VAT: The indicated price is exclusive of VAT

VAT/margin scheme: VAT deductible for businesses

Delivery and trade-in are possible at any time for all industrial equipment

Glenn Smeets

Dražba

Dražba končana

Piemonte

Piemonte

591 km

Obdelovalni center

WEEKEVANTAGE 24 L

Stanje: pripravljen za uporabo (rabljen), Leto izdelave: 2010, Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 3.700 mm, pomik osi Y: 1.550 mm, hitrost pomika os X: 96 m/min, hitrost podajanja osi Y: 96 m/min, največja hitrost vrtenja: 24.000 obr/min, DÉTAILS TECHNIQUES

Course axe X : 3 700 mm

Course axe Y : 1 550 mm

Course axe X (levée) : 4 538 mm

Course axe Y (levée) : 1 952 mm

Passage maximal de la pièce : 100 mm

Vitesse de déplacement axe X : 96 m/min

Vitesse de déplacement axe Y : 96 m/min

Vitesse de déplacement axe Z : 25 m/min

Nombre d’axes commandés : 3 axes

Nombre de broches de perçage : 7

Nombre de positions d’outils : 8

Table de nesting

Longueur : 1 550 mm

Largeur : 3 700 mm

Matériau : Bakélite

Nombre de pompes : 4

Capacité individuelle : 108 m³/h

Lrjdpoxw Up Ssfx Abbsg

Unité de perçage

Unité : supérieure

Broches pour perçages verticaux : 7

Unité de fraisage

Unité : supérieure

Nombre d’axes commandés : 3

Changeur d’outils automatique : oui

Puissance du moteur : 9 kW

Vitesse max. : 24 000 tr/min

DÉTAILS MACHINE

Puissance totale installée : 26 kW

ÉQUIPEMENT

Pompe à vide

Système de contrôle PC85

Logiciel WoodWOP

Marquage CE

Rideaux immatériels de sécurité

Remarque : Les outils ne sont pas compris dans l’offre.

Dražba

Dražba končana

Piemonte

Piemonte

591 km

Obdelovalni center

REICHENBACHERARTIS X

Stanje: pripravljen za uporabo (rabljen), Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 2.500 mm, pomik osi Y: 1.300 mm, največja hitrost vretena: 18.000 obr/min, število osi: 5, TEHNIČNI PODATKI

Pomik osi X: 2.500 mm

Pomik osi Y: 1.300 mm

Število mest za orodja: 16

Vrtalna enota

Enota: zgoraj

Vreten za vertikalno vrtanje: 7

Skupno število vertikalnih in horizontalnih vreten: 7

Ljdjxw Ukcopfx Abbjrg

Rezkalna enota

Enota: zgoraj

Število kontroliranih osi: 5

avtomatska menjava orodij

Moč motorja: 7 kW

Največje število vrtljajev: 18.000 obr/min

PODROBNOSTI O STROJU

Nameščena skupna moč: 20 kW

OPREMA

Nesting

Zaščitna struktura enot

Varnostni senzorji

Na stroj pritrjene zaščitne ograje

Dražba

Dražba končana

Piemonte

Piemonte

591 km

Obdelovalni center

WEEKEPROFI BHC912/43/25

Stanje: pripravljen za uporabo (rabljen), Leto izdelave: 2012, Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 2.500 mm, pomik osi Y: 4.300 mm, največja hitrost vrtenja: 24.000 obr/min, Oprema: CE označba, TECHNICAL DETAILS

Lrjdpjxw Ugdofx Abbsg

X-axis travel: 2,500 mm

Y-axis travel: 4,300 mm

Maximum workpiece clearance: 60 mm

Spindle speed (Milling Unit 1): 24,000 rpm

Spindle speed (Milling Unit 2): 24,000 rpm

Spindle speed (Milling Unit 3): 24,000 rpm

Number of controlled axes (Milling Unit 1): 4

Number of controlled axes (Milling Unit 2): 3

Number of controlled axes (Milling Unit 3): 3

MACHINE DETAILS

Number of working zones: 2

Number of clamps: 9+4

Motor power (Milling Unit 1): 12 kW

Motor power (Milling Unit 2): 12 kW

Motor power (Milling Unit 3): 12 kW

Tool magazine 1: 14 positions, mounted on the side of the machine

Tool magazine 2: 14 positions, mounted on the side of the machine

EQUIPMENT

Clamps for securing the workpiece

Automatic panel loading system

Motorized transfer

Automatic tool changer

Barcode label printer

CE marking

Safety guards mounted on the machine

Note: Tools and the automatic chip extraction system are not included in the offer.

Mali oglas

Hagenbrunn

Hagenbrunn

268 km

Obdelovalni center

CNC4ALL GmbHPortal-Fräse Professional 1200x600

Klic

Stanje: novo, potovalna razdalja osi X: 600 mm, pomik osi Y: 1.200 mm, pomik po osi Z: 150 mm, največja hitrost vretena: 24.000 obr/min, moč vretenovega motorja: 2.200 W, število vreten: 1, Oprema: vrtilna hitrost brezstopenjsko nastavljiva, CNC4ALL Professional 1200 × 600

💪 Compact Precision CNC Milling Machine – powerful, versatile & in stock!

Features (Premium Configuration):

💨 2.2 kW Milling Spindle (water-cooled) – powerful & quiet for continuous operation

⚙️ 9 Nm Stepper Motors (micro-stepping) – precise movement & smooth running

💧 Minimum-Quantity Lubrication – extends tool life & reduces maintenance

🌪️ Extraction Hood – clean workspace & clear view while milling

🔄 Rotary Axis D 80 mm × 900 mm – ideal for round parts, engravings & 3D machining

❄️ Milling Spindle Cooling System – consistent temperature for long service life

🧲 Vacuum Pump (side channel blower) – secure clamping of large or small workpieces

💻 Control Software Included – Plug & Play: connect, start, mill!

📐 Technical Data:

* Working Area: 1200 × 600 × 150 mm

* Accuracy: Positioning ± 0.02 mm | Repeatability ± 0.03 mm

* Travel Speed: up to 8,000 mm/min

* Guide System: Hiwin linear guides, size 20 mm

* Drive: TBI ball screws

* Machine Table: cast iron table with T-slot & vacuum table combination

* Frame: welded steel subframe, CNC-machined for flatness & stability

🚀 Your Advantages at a Glance:

✅ In stock – immediate availability & delivered ready to operate!

✅ Compact design with industrial precision – perfect for workshops & small series

✅ High performance for wood, plastic, aluminium & composite materials

✅ Clean, efficient production thanks to extraction hood & minimum-quantity lubrication

✅ Flexible with rotary axis & vacuum table – for flat and round workpieces

✅ User-friendly control – quick setup & easy operation

🪵 Ideal for:

Carpentry shops • Model makers • Signmaking • Prototyping • Plastics & aluminium processing

📦 Act now!

The CNC4ALL Professional 1200 × 600 offers precision, power and reliability in a compact format – in stock & ready to use immediately.

Lrjdpsxwdkrefx Abbeg

👉 Contact us now for your personal quote or a demonstration in our showroom.

Mali oglas

Hagenbrunn

Hagenbrunn

268 km

Obdelovalni center

CNC4ALL GmbHPortal-Fräsmaschine Industry 3000x1500

Klic

Stanje: novo, Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 1.500 mm, pomik osi Y: 3.000 mm, pomik po osi Z: 200 mm, hitro pomikanje X-os: 25.000 m/min, hitri pomik os Y: 25.000 m/min, hitri pomik na osi Z: 25.000 m/min, dolžina obdelovanca (maks.): 3.000 mm, širina obdelovanca (maks.): 1.500 mm, skupna masa: 1.600 kg, hitrost vretena (min.): 12.000 obr/min, največja hitrost vretena: 24.000 obr/min, dovod hladilne tekočine: 3 letvica, število vreten: 1, Oprema: vrtilna hitrost brezstopenjsko nastavljiva, 🚀 CNC4ALL Industry 3000 × 1500 CNC Router / Gantry Milling Machine

High-performance CNC milling machine – in stock & ready to operate!

Premium Features:

💪 5.5 kW spindle motor (water-cooled) – robust power for precision machining of wood, plastics, aluminium & composite materials

⚙️ Servo motors on all axes – high dynamics, exact repeatability and smooth running

🧲 Vacuum pump (side channel blower) – optimal workpiece clamping on the vacuum table, even for large-format materials

🌪️ Extraction hood – keeps the working area clean

💧 Minimum quantity lubrication – extends tool life, reduces coolant consumption and ensures clean results

🔧 Technical Highlights

* Working area: 3000 × 1500 × 200 mm

* Repeat accuracy: ± 0.03 mm

Ledpfsxwc Ipox Abbjrg

* Traversing speed: up to 25,000 mm/min

* Robust welded steel frame for maximum stability

* Hiwin linear guides and rack & pinion / ball screw drives for precise movements

* User-friendly CNC software control (included)

✅ Your Advantages

* Immediately available – no waiting time!

* Delivered fully operational – connect, switch on, and start milling

* Ideal for joiners, sign makers, and industrial companies

* Efficient, quiet, and low-maintenance – for continuous professional use

📞 Get information & secure your offer now!

The CNC4ALL Industry 3000 × 1500 combines power, precision and reliability in industrial quality – and is ready for immediate use in your company.

👉 Contact us now for an individual quote or a live demonstration in our showroom

Znak zaupanja

Prodajalci, certificirani pri Machineseeker

Mali oglas

Varaždin

Varaždin

105 km

Obdelovalni Center

SCMmorbidelli x400

Klic

Stanje: zelo dobro (rabljeno), Leto izdelave: 2023, Funkcionalnost: popolnoma funkcionalen, CNC stroj Morbidelli X 400 z ravno (gnezdenje) mizo

Lodpfxoxqzm Ds Abberg

Mali oglas

Plzeň-město

Plzeň-město

418 km

Obdelovalni center

Format4Profit H10

Klic

Stanje: zelo dobro (rabljeno), Leto izdelave: 2022, Funkcionalnost: popolnoma funkcionalen, številka stroja/vozila: S/N 320.01.001.22, potovalna razdalja osi X: 4.150 mm, pomik osi Y: 2.560 mm, pomik po osi Z: 280 mm, hitro pomikanje X-os: 100 m/min, hitri pomik os Y: 100 m/min, hitri pomik na osi Z: 30 m/min, dolžina podajanja os X: 4.150 mm, dolžina pomika po osi Y: 2.560 mm, dolžina podajanja os Z: 280 mm, hitrost pomika os X: 25 m/min, hitrost podajanja osi Y: 25 m/min, hitrost podajanja os Z: 15 m/min, nazivna (navidezna) moč: 35 kVA, proizvajalec krmilnikov: WoodFlash 4.1, model krmilnika: H10 CNC Control, Windows 10, dolžina obdelovanca (maks.): 3.120 mm, širina obdelovanca (maks.): 2.160 mm, višina obdelovanca (maks.): 105 mm, skupna višina: 2.510 mm, skupna dolžina: 11.848 mm, skupna širina: 4.850 mm, širina mize: 2.100 mm, višina mize: 895 mm, dolžina mize: 3.200 mm, skupna masa: 4.500 kg, največja hitrost vretena: 24.000 obr/min, moč vretenovega motorja: 10.000 W, število vreten: 1, število mest v zalogovniku orodij: 8, vhodna napetost: 400 V, CNC obdelovalni center / 3-osni CNC rezkar Format 4 Profit H102232

S/N 320.01.001.22, letnik 2022, s krmiljenjem, držalo za orodje HSK63,

gibi osi: X-os = cca 4.050 mm, Y-os = cca 2.560 mm,

Z-os = cca 280 mm, zraven 2 vakuumski črpalki Becker VTLF2.250/0-79,

letnik 2021, z vključenim nakladalnim mizo, izhodnim trakom, 8-kratnim menjalcem orodij,

obdelovalna površina cca 2.800 x 2.060 mm, utorni agregat v smeri x in y,

Lodpfsxy Abusx Abborg

horizontalno vrtanje v smeri x in y, po dve vreteni, vrtalni agregat DH 16,

vertikalno vrtanje 5x v smeri y in 7x v smeri x, glavno vreteno cca 10 kW,

hitrost osi x cca 100 m/min, hitrost osi y cca 100 m/min, hitrost osi z cca 30 m/min.

Mali oglas

Plzeň-město

Plzeň-město

418 km

Obdelovalni center

Format4Profit H10

Klic

Stanje: zelo dobro (rabljeno), Leto izdelave: 2017, Funkcionalnost: popolnoma funkcionalen, številka stroja/vozila: S/N 320.09.003.17,, potovalna razdalja osi X: 4.150 mm, pomik osi Y: 2.560 mm, pomik po osi Z: 280 mm, hitro pomikanje X-os: 100 m/min, hitri pomik os Y: 100 m/min, hitri pomik na osi Z: 30 m/min, dolžina podajanja os X: 4.150 mm, dolžina pomika po osi Y: 2.560 mm, dolžina podajanja os Z: 280 mm, hitrost pomika os X: 25 m/min, hitrost podajanja osi Y: 25 m/min, hitrost podajanja os Z: 15 m/min, nazivna (navidezna) moč: 28 kVA, proizvajalec krmilnikov: WoodFlash 4.1, model krmilnika: H10 CNC Control, Windows 10, dolžina obdelovanca (maks.): 3.120 mm, širina obdelovanca (maks.): 2.160 mm, višina obdelovanca (maks.): 105 mm, skupna višina: 2.510 mm, skupna dolžina: 11.848 mm, skupna širina: 4.850 mm, širina mize: 2.100 mm, višina mize: 895 mm, dolžina mize: 3.200 mm, skupna masa: 4.500 kg, največja hitrost vretena: 24.000 obr/min, moč vretenovega motorja: 10.000 W, število vreten: 1, število mest v zalogovniku orodij: 8, vhodna napetost: 400 V, Oprema: dokumentacija / priročnik, CNC obdelovalni center 3-osni CNC rezkar Format 4 Profit H10 2232

S/N 320.09.003.17

Leto izdelave 2017

Nosilec orodja HSK63F

Pomiki osi:

X-os: približno 4.050 mm,

Y-os: približno 2.560 mm,

Z-os: približno 280 mm,

vključno z 2 vakuumskima črpalkama Becker VTLF2.250/0-79,

leto izdelave 2017,

vključno z nakladalno mizo in izhodnim trakom

Menjalnik orodij za 8 orodij

Obdelovalna površina približno 2.800 x 2.060 mm

Rezkalna enota v smeri x in y

Vodoravno vrtanje v smeri x in y, po dva vretena, vrtalni agregat DH 16,

Navpično vrtanje 5x v smeri y in 7x v smeri x, glavno vreteno približno 10 kW,

Hitrost osi x približno 100 m/min, hitrost osi y približno 100 m/min, hitrost osi z približno 30 m/min

Lredpfxjxy Abhs Abbsg

Mali oglas

Plzeň-město

Plzeň-město

418 km

Obdelovalni center

Format4Profit H10

Klic

Stanje: zelo dobro (rabljeno), Leto izdelave: 2017, Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 4.150 mm, pomik osi Y: 2.560 mm, pomik po osi Z: 280 mm, hitro pomikanje X-os: 100 m/min, hitri pomik os Y: 100 m/min, hitri pomik na osi Z: 30 m/min, dolžina podajanja os X: 4.150 mm, dolžina pomika po osi Y: 2.560 mm, dolžina podajanja os Z: 280 mm, hitrost pomika os X: 25 m/min, hitrost podajanja osi Y: 25 m/min, hitrost podajanja os Z: 15 m/min, nazivna (navidezna) moč: 11 kVA, vrtilni moment: 4 Nm, proizvajalec krmilnikov: WoodFlash 4.1, model krmilnika: H10 CNC Control, Windows 10, dolžina obdelovanca (maks.): 3.120 mm, širina obdelovanca (maks.): 2.160 mm, višina obdelovanca (maks.): 105 mm, skupna višina: 2.510 mm, skupna dolžina: 11.848 mm, skupna širina: 4.850 mm, širina mize: 2.100 mm, višina mize: 895 mm, dolžina mize: 3.200 mm, skupna masa: 4.500 kg, največja hitrost vretena: 24.000 obr/min, moč vretenovega motorja: 10.000 W, število vreten: 1, število mest v zalogovniku orodij: 8, vhodna napetost: 400 V, Oprema: dokumentacija / priročnik, vrtilna hitrost brezstopenjsko nastavljiva, CNC obdelovalni center 4-osni CNC rezkar Format 4 Profit H10 2232

S/N 320.09.002.17

Letnik 2017

Vpenjanje orodij HSK63F

Pomiki osi:

X-os = pribl. 4050 mm,

Y-os = pribl. 2560 mm,

Z-os = pribl. 280 mm,

C-os

vključuje 2 vakuumski črpalki Becker VTLF2.250/0-79,

Letnik 2017

vključno z nakladalno mizo in izhodnim trakom

Menjalnik orodij za 8 orodij

Obdelovalna površina cca. 2800 x 2060 mm

Lrjdpfx Abexy Aa Dobog

Ploščna žaga v x- in y-smeri

Horizontalno vrtanje v x- in y-smeri, po dve vreteni, vrtalna enota DH 16,

Vertikalno vrtanje 5x v smeri y in 7x v smeri x, glavna vretena cca. 10 kW,

Hitrost x-os cca. 100 m/min, hitrost y-os cca. 100 m/min, hitrost

z-os cca. 30 m/min

Olajšamo vam iskanje

Nove ponudbe prejmete takoj in brezplačno po e-pošti.

Iskalno nalogo lahko kadar koli preprosto končate.

Rabljeni obdelovalni centri z ravno ali mrežasto mizo (347)

Zdaj preiščite celoten Machineseeker z več kot 200.000 rabljenimi stroji.Brskajte po najbolj priljubljenih poimenovanjih strojev:

- Bar Obdelovalni Center

- Cnc Obdelovalni Center

- Cnc Rezkalni Stroj In Obdelovalni Center

- Ex Tiskovno Središče

- Lesa Obdelovalni Center

- Mlin Za Mletje

- Moehle Mlin Za Meso

- Nakladalec S Rovokopači

- Obdelovalni Center

Izvedite več zdaj

+44 20 806 810 84

+44 20 806 810 84

Objavite oglas zdaj

*na oglas/mesec