Zerma Granulator nakup rabljenega (52)

Razvrsti rezultate

- Najnižja cena Najvišja cena

- Najnovejši oglasi Najstarejši oglasi

- Najkrajša razdalja Največja razdalja

- Najnovejše leto izdelave Najstarejše leto izdelave

- Zadnja posodobitev Najstarejša posodobitev

- Proizvajalci od A do Ž Proizvajalec od Z do A

- Pomembnost

- Najnižja cena

- Cena

- Najvišja cena

- Cena

- Najnovejši oglasi

- Datum objave

- Najstarejši oglasi

- Datum objave

- Najkrajša razdalja

- Razdalja

- Največja razdalja

- Razdalja

- Najnovejše leto izdelave

- Leto izdelave

- Najstarejše leto izdelave

- Leto izdelave

- Zadnja posodobitev

- Nazadnje posodobljeno

- Najstarejša posodobitev

- Nazadnje posodobljeno

- Proizvajalci od A do Ž

- Proizvajalec

- Proizvajalec od Z do A

- Proizvajalec

- Oznaka od A do Ž

- Oznaka

- Oznaka od Z do A

- Oznaka

- Model od A do Ž

- Model

- Model od Z do A

- Model

- Najnižja referenca

- referenca

- Najvišja referenca

- referenca

- Najkrajši obratovalni čas

- Obratovalni čas

- Najdaljši čas obratovanja

- Obratovalni čas

- Pomembnost

- Pomembnost

Zerma

Mali oglas

Zuzenhausen

Zuzenhausen

581 km

Rezalni mlini

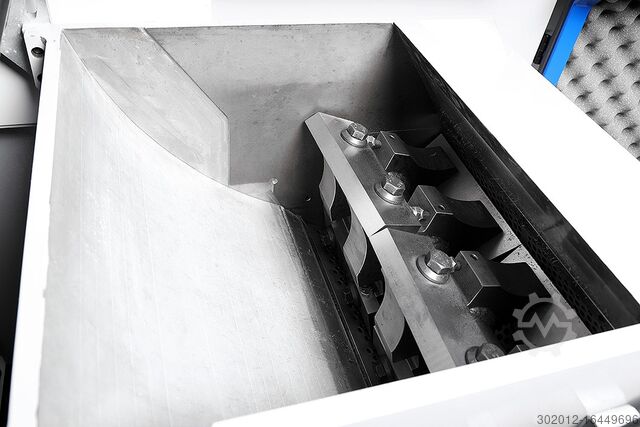

ZERMAGSH 800/1600

Klic

Stanje: rabljeno, številka stroja/vozila: 12897, Rotor diameter: 800 mm

Rotor width: 1600 mm

Rotor knives: 7

Stator knives: 2

Redowbwwvopfx Ad Tebt

Infeed opening approx. 800 x 1600 mm

Drive motor: 160 kW

Mali oglas

Zuzenhausen

Zuzenhausen

581 km

Stranski mlini

ZERMAGSL 180

Klic

Stanje: novo, številka stroja/vozila: Baureihe GSL 180 / Neumaschine, The ZERMA GSL series beside-the-press granulators, models 180/120 to 180/430, were specifically developed as slow-speed granulators for injection molding applications. They feature a rotor diameter of 180 mm and working widths ranging from 120 to 430 mm. The rotor is directly driven by a gear motor. The special rotor blades can be resharpened multiple times.

Material is fed in via a noise-reduced intake hopper constructed in a sandwich design, which is available in various versions depending on the type of feed. Depending on the application, these granulators are mounted on either a low or high base frame and equipped with a suitable suction or discharge chute. With numerous options available, the beside-the-press granulators are extremely versatile in use.

Apart from the standard advantages of all slow-speed granulators, such as low noise emissions and virtually dust-free regrind, the GSL 180/120 to GSL 180/430 series particularly stand out due to their blade, rotor, quick-snap system, and superior accessibility.

Rbodpfxjghgbds Ad Tst

Mali oglas

Zuzenhausen

Zuzenhausen

581 km

Rezalni mlini

ZERMAEinstufige Schneidmühlenanlage Zuführband - GSE 300/600 - Absauganlage

Klic

Stanje: rabljeno, številka stroja/vozila: 13237 13238, - Feed conveyor 0.75 kW

- GSE 300/600 #13237

Rotor diameter: 300 mm

Rotor width: 600 mm

Rotor knives: 3

Stator knives: 2

Feed opening approx. 300 x 600 mm

Drive motor: 18.5 kW

- MFT 20-250 big-bag extraction system

Rodpfx Aowbwxted Tsbt

Izvedite več zdaj

+44 20 806 810 84

+44 20 806 810 84

Objavite oglas zdaj

*na oglas/mesec

Mali oglas

Zuzenhausen

Zuzenhausen

581 km

Rezalni mlini

ZERMAGS 300/400 N

Klic

Stanje: rabljeno, številka stroja/vozila: 13206, Rotor diameter: 300 mm

Rotor width: 400 mm

Rotor knives: 3

Stator knives: 2

Feed opening approx. 300 x 400 mm

Rjdpfxjwikaas Ad Tobt

Drive motor: 15 kW

Mali oglas

Zuzenhausen

Zuzenhausen

581 km

Rezalni mlini

ZERMAGS 500/800

Klic

Stanje: rabljeno, številka stroja/vozila: 12883, Rotor width: 800 mm

Rsdpfxowbwqve Ad Tjbt

Rotor knives: 5

Stator knives: 4

Feed opening approx. 500 x 800 mm

Drive motor: 45 kW

Odkrijte več rabljenih strojev

Mali oglas

Zuzenhausen

Zuzenhausen

581 km

Drobilnik

ZERMAZHS 1100

Klic

Stanje: rabljeno, številka stroja/vozila: 13187, Rotor diameter: 400 mm

Rotor width: 1100 mm

Rotor knives: 54

Stator knife rows: 1

Feed opening approx. 1100 x 1500 mm

Rsdpfx Aewbwvljd Tobt

Drive motor: 37 kW

Mali oglas

Zuzenhausen

Zuzenhausen

581 km

Drobilnik

ZERMAZWS

Klic

Stanje: novo, The cost-effective single-shaft shredders of the ZWS series can handle a wide range of shredding tasks, such as preliminary size reduction for subsequent briquetting, for producing wood chips for combustion, or for reintroduction into the particleboard industry. Depending on throughput and material, the machines can be further customized to meet specific requirements.

Typical feed materials for shredding include:

Rjdpjghgdgsfx Ad Tobt

- Large panel and board offcuts

- Wooden pallets

- Waste from joinery workshops

- Packaging timber

- Construction and demolition wood

- Veneers, MDF, and particle boards

Mali oglas

Zuzenhausen

Zuzenhausen

581 km

Kompaktni rezalni mlini

ZERMAGSC

Klic

Stanje: novo, številka stroja/vozila: Baureihe GSC / Neumaschine, The compact granulators of the GSC series are fully sound-insulated granulators, making them particularly quiet in operation. The integrated soundproofing, thanks to its well-thought-out design, ensures ideal accessibility to the granulator itself as well as for knife and screen changes. The noise protection is based on the use of state-of-the-art sound insulation materials.

Rbodpfeghgbwsx Ad Tst

The housings are manufactured from a robust steel-welded construction, which, in combination with the V-cut rotors (except for GSC 300/300), ensures a long service life and universal applicability. The tangential housing geometry allows the rotor to effectively accept and process even bulky feed materials.

All machines in the GSC series consistently deliver high-quality regrind, regardless of whether the feed material consists of injection or blow moldings, profiles, sheets, or film.

The GSC series models are cost-effective, highly reliable, easy to clean, and offer a long service life.

Integrated Sound Insulation:

The integrated sound insulation ensures a pleasant working environment with low noise levels. The optimized design guarantees ideal accessibility to the machine.

Mobile Compact Design:

The integrated sound insulation makes the granulators compact and mobile. The machines can be moved to any desired location using a pallet truck or forklift.

ZERMA offers a wide range of options such as extraction systems, conveyors, metal detectors, and fine material separators.

Mali oglas

Zuzenhausen

Zuzenhausen

581 km

Drobilnik

ZERMAZWS 600 SMART

Klic

Stanje: novo, številka stroja/vozila: ZWS 600 SMART, The ZWS 600 SMART serves as a supplement to the ZWS series. This product line was specifically designed as a cost-effective solution for shredding wood waste in small and medium-sized woodworking companies.

AT A GLANCE:

- Compact design

- Robust welded steel construction

- Large-volume hopper for material infeed

- Solid steel rotor with bolted knife holders

- PLC control for fully automatic operation

Technical data SMART 600:

- Infeed opening: 600 x 840 mm

- Motor: 11 / 15 kW

- Rotor diameter: 250 mm

- Rotor speed: 80 – 120 rpm

- 13 rotor knives

Redpfxsghgdcj Ad Tjbt

Technical data SMART 600 S:

- Infeed opening: 600 x 840 mm

- Motor: 18.5 / 22 / 30 kW

- Rotor diameter: 250 mm

- Rotor speed: 80 – 120 rpm

- 26 rotor knives

Mali oglas

Zuzenhausen

Zuzenhausen

581 km

Drobilnik

ZERMAZHS

Klic

Stanje: novo, ZHS 600 - 18.5/22 kW

Rotor diameter: 400 mm

Working cross-section: 520 x 470 mm

ZHS 850 - 30 kW

Rotor diameter: 400 mm

Working cross-section: 800 x 820 mm

ZHS 1100 - 37 kW

Rotor diameter: 400 mm

Working cross-section: 1,080 x 1,040 mm

ZHS 1400 - 55 kW

Rotor diameter: 400 mm

Working cross-section: 1,400 x 1,380 mm

ZHS 1500 - 90/110 kW

Rotor diameter: 600 mm

Working cross-section: 1,360 x 1,430 mm

ZHS 1700 - 75 kW

Rotor diameter: 400 mm

Working cross-section: 1,640 x 1,550 mm

ZHS 2000 - 2 x 90 kW

Rotor diameter: 400/600 mm

Working cross-section: 1,920 x 1,550 mm

ZHS 2600 - 2 x 90 kW

Rotor diameter: 400/600 mm

Working cross-section: 2,480 x 1,550 mm

ZHS – the Economical All-rounder

The ZHS series features a load-dependent, hydraulically controlled pusher that feeds material horizontally towards the rotor in a slightly inclined position. The material is cut between the rotor and stator knives until it passes through the bolted, replaceable screen installed beneath the rotor. The replaceable screen determines the final particle size. The shredded material can be discharged via conveyor belt, discharge screw, or pneumatically using an extraction system.

The single-shaft shredders of the ZHS series are designed for light to medium-duty applications in the plastics industry.

Rbjdpfoghgdkjx Ad Tjt

Technical Details:

- Roller-mounted hydraulic pusher with horizontal movement

- Bolted knives and knife holders

- Optional segmented bed for processing particularly thin parts and materials

- Rotor aggressiveness can be reduced or increased using bolted filler pieces

- Can be integrated in a two-stage plant with a granulator as a pre-shredder

Mali oglas

Zuzenhausen

Zuzenhausen

581 km

Shredder

ZERMAZRS

Klic

Stanje: novo, The solution for shredding large, long pipes and profiles. The ZRS series is specifically designed for the size reduction of pipes with diameters up to 1,300 mm and made from various materials such as PE, PP, and PVC.

Rsdpfx Asghgd Ied Tobt

These machines are capable of directly shredding plastic pipes up to 9 meters in length without the need for pre-cutting or sawing. At the heart of the system are rotors with diameters of up to 1,500 mm, which can be equipped with up to 206 cutting crowns and gently process the material at low rotational speed.

The pipe is fed into an enclosed feed trough, where it is pressed against the rotor by a hydraulic pusher. The pre-shredded material is then conveyed via a belt to a granulator. The granulator reduces the material to directly processable regrind.

The entire system is automatically controlled via a central control unit. Further advantages of the system include low energy consumption, prevention of power peaks, and minimization of accident risks during the pre-shredding process.

Mali oglas

Zuzenhausen

Zuzenhausen

581 km

Rezalni mlini

ZERMAGSH

Klic

Stanje: novo, številka stroja/vozila: GSH, The ZERMA granulators of the GSH series are exceptionally robust machines designed for the most demanding applications, tailored to meet the versatile requirements of modern recycling operations.

Constructed from heavy-duty steel weldments, the housings withstand even extraordinary stresses. Bearings, knife mounting, and rotor shafts are significantly oversized, making them extremely durable. By simply reconfiguring the setup, massive lumps and thick-walled pipes, as well as hollow bodies and films, can be processed effortlessly.

Depending on the specific application (including for temperature-sensitive materials), different rotor designs are available. However, all share a common feature: advanced and superior V-cut technology.

Rsdpfx Asghgfled Tobt

All machines in the GSH series consistently deliver high-quality granulate, whether from bottle crates, profiles, sheets, films, start-up lumps, or pipes. They are economical, highly reliable, easy to clean, and feature a long service life.

When combined with ZERMA's comprehensive range of options, accessories (such as extraction systems, conveyor belts, metal detectors, fine material separators, roller feed systems, etc.), and spare parts, you receive a customized and optimized shredding system. The benefits include significantly reduced costs, time, and personnel requirements.

Innovative Housing Design

The housing is split diagonally in the middle, and the upper section with infeed hopper can be opened hydraulically to provide full access to the rotor for tool changes and cleaning. The screen insert is also held by a hydraulically tilting basket, offering optimal accessibility for screen removal and installation. The screen insert is reversible.

Robust External Bearing Design

Another well-conceived design feature is the externally mounted bearing assembly. Heavy-duty roller bearings in steel housings ensure long service life and are ideal for the toughest applications. The external bearings prevent grease from entering the cutting chamber and, conversely, prevent granulate or fine particles from entering the bearing assembly. This presents a significant advantage, especially during wet operation.

Flywheel

To compensate for shock loads during granulation, an optional flywheel is available. The rotors come standard with a secondary shaft end for this purpose.

High Operational Safety

All granulators comply with EU machinery directives and are CE-certified. Safety features include, for example, run-down guards with limit switches and hydraulically unlockable check valves.

Mali oglas

Soerendonk

Soerendonk

897 km

Granulator / drobilnik

Pallmann / ZermaPS 4 - 7,5 F

Klic

Stanje: skoraj kot novo (rabljeno), “Pallmann PS 4-7.5 F – Cutting Mill” for sale

You can find our complete stock list on our website.

Manufacturer: Pallmann

Model: PS 4 – 7.5 F

Machine No.: 2264036

With 75 kW drive.

With base frame.

The cutting mill is currently being overhauled, sandblasted, and repainted.

Rsdpjglvv Ujfx Ad Tjbt

Mali oglas

Brahlstorf

Brahlstorf

854 km

Stranski mlin

ZERMAGSL 180/430

Klic

Leto izdelave: 2025, Stanje: novo, Slow-speed beside-the-press granulator

Rotor diameter (mm): 180

Rotor width (mm): 430

Rotor speed (rpm): 150

Drive power (kW): 4

Number of rotor knives: 45

Number of stator knives: 2

Screen perforation (mm): >5

Weight approx. (kg): 250

The slow-speed beside-the-press granulators of the GSL series are primarily used in injection molding and blow molding applications for inline granulation of sprues and defective parts. With various hopper and extraction systems, the machines can be flexibly integrated into existing installations.

Rbedpfxsi Hpfdj Ad Tst

GSL 180 — Designed for granulating sprues from injection molding and blow molding processes

Highlights of the GSL series:

- Low noise operation due to slow rotor speed, angled cutting design, and multi-layer sandwich-constructed soundproof hopper

- Powerful and efficient drive system with branded gearbox

- Easy maintenance, cleaning, and knife replacement

The slow-speed beside-the-press granulators of the GSL 180 series feature a closed rotor with a diameter of 180 mm. The machines are available with working widths from 120 mm up to 430 mm.

The rotor consists of individual disks, which are directly connected to the spur gear drive via an oversized drive shaft. This ensures efficient and low-maintenance power transmission.

The material to be granulated can be fed manually, by conveyor, or robot through a generously sized, soundproofed sandwich-constructed hopper. By default, the granulator is mounted on a low-profile frame with swivel castors. Discharge is carried out via a suction trough positioned beneath the screen, equipped with a pipe connection for a vacuum conveyor.

Applications

The slow-speed beside-the-press granulators of the GSL 180 series are specially designed for the granulation of sprues from injection molding and blow molding processes. Easy accessibility allows for rapid color and material changes. The low rotor speed enables the processing of both soft and hard materials and ensures good material quality with minimal dust generation.

Mali oglas

Brahlstorf

Brahlstorf

854 km

Počasno delujoči rezalni mlin

ZERMAGSL 300/400

Klic

Leto izdelave: 2024, Stanje: novo, Direct drive via gear motor

No adjustment work required thanks to special rotor knives

Easy access for maintenance and cleaning

Low noise emissions and low-dust granulate

thanks to slow rotor speed

Universally applicable with numerous options

Rotor diameter (mm): 300

Rotor width (mm): 400

Rbjdpfjn Hqxfex Ad Tot

Rotor speed (rpm): 150

Drive power (kW): 7.5

Number of rotor knives: 33

Number of stator knives: 2

Screen perforation (mm): > 6

Approx. weight (kg): 550

Mali oglas

Brahlstorf

Brahlstorf

854 km

Mlin za zmanjševanje velikosti

ZERMAGSL 180/180

Klic

Leto izdelave: 2024, Stanje: novo, Slow-running beside-the-press granulator

Rotor diameter (mm): 180

Rotor width (mm): 180

Rotor speed (rpm): 150

Drive (kW): 3

Number of rotor knives: 18

Number of stator knives: 2

Screen perforation (mm): >5

Weight approx. (kg): 140

The slow-running beside-the-press granulators of the GSL series are primarily used in injection moulding and blow moulding for inline size reduction of sprues and defective parts. With various hopper and extraction systems available, these machines can be flexibly integrated into existing installations.

GSL 180 For granulating sprues from injection moulding and blow moulding processes

Highlights of the GSL series:

- Low noise operation due to the rotor’s low speed, inclined cut, and a multi-layer, sound-insulated hopper in sandwich construction

- Powerful and efficient drive thanks to branded gear units

- Easy maintenance, cleaning, and knife change

Rsdpfoqmik Isx Ad Tobt

The slow-running beside-the-press granulators of the GSL 180 series feature a closed rotor with a diameter of 180 mm. The machines are available in working widths from 120 mm up to 430 mm. The rotor consists of individual discs directly connected to the spur gear via an oversized drive shaft, ensuring efficient and low-maintenance power transmission.

The material to be granulated can be fed manually, via conveyor belt, or by robot through the generously sized, sound-insulated hopper with sandwich construction. As standard, the granulator is mounted on a low base frame with swivel castors. Discharge is via a suction pan mounted under the screen, with a pipe connection for a suction conveyor.

Applications

The slow-running beside-the-press granulators of the GSL 180 series are specifically designed for granulating sprues generated in injection moulding and blow moulding applications. The easy accessibility of the machine allows for quick colour and material changes. The low rotor speed also enables the processing of both soft and hard materials, guaranteeing high-quality material output with minimal dust.

Mali oglas

Brahlstorf

Brahlstorf

854 km

Hitri granulator

ZERMAGST 250/450

Klic

Leto izdelave: 2024, Stanje: novo, Optimization of an established concept.

Shredding of large-volume blow-molded parts as well as start and end pieces

The compact redesign integrates the best features of the proven GST and GSC series, with a particular focus on weight, handling, and energy efficiency. These compact granulators are equipped with complete sound insulation, resulting in ultra-quiet operation. The granulators are available with a 250 mm rotor diameter and widths of 300, 450, and up to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material blockages. As with all ZERMA granulators, both rotor and stator knives can be adjusted outside the machine, minimizing maintenance downtime.

The pronounced tangential, curved rear wall of the cutting chamber, combined with the aggressive, open rotor design, ensures reliable material feeding and minimizes the risk of blockages.

These compact granulators are suitable for blow-molding operations and ideal for recycling large parts such as bottles, jerrycans, and crates. Thanks to their low feed height, they can be easily loaded by hand or with a small conveyor belt. Low noise emissions and a small footprint make these granulators the perfect solution for inline granulation.

Optional rear wall with raised stator knife (M version):

The feed method with a higher-positioned stator knife is especially suited for thick-walled and more compact parts, such as injection-molded components, profiles, sheets, etc. The cutting geometry and the rotor’s reduced aggressiveness result in high-quality regrind, regardless of the material’s type or form (e.g. injection-molded parts, profiles, sheets, etc.).

Control system and control cabinet:

The integrated control system and operator console fully comply with all applicable safety regulations and can be tailored to specific requirements. In addition, peripheral equipment such as infeed conveyors, metal detection systems, and discharge units can be seamlessly integrated into the machine’s control system. An optional intelligent energy-saving function is available to improve efficiency, automatically reducing power consumption during idle times and starting or stopping the system based on the status of upstream machines.

Standard configuration with blower, 0.75 kW power consumption, and 400 cyclone

Rotor diameter (mm): 250

Rotor width (mm): 450

Drive (kW): 7.5

Number of rotor knives: 3 x 2

Number of stator knives: 2

Redpfx Asp Sr H Dsd Tebt

Screen perforation (mm): > 6

Weight approx. (kg): 700

Feed opening (mm): 380 x 450

Feed opening for M version option (mm): 295 x 450

Mali oglas

Brahlstorf

Brahlstorf

854 km

Stranski mlin

ZERMAGSL 180/180

Klic

Leto izdelave: 2024, Stanje: novo, Slow-Speed Granulator

Rotor Diameter (mm): 180

Rotor Width (mm): 180

Rotor Speed (rpm): 150

Drive (kW): 3

Number of Rotor Blades: 18

Number of Stator Blades: 2

Screen Perforation (mm): >5

Weight approx. (kg): 140

The slow-speed granulators of the GSL Series are primarily used in injection moulding and blow moulding applications for inline granulation of sprues and defective parts. Various hopper and extraction systems allow for flexible integration of the machines into existing installations.

GSL 180 For granulating sprues in injection moulding and blow moulding processes.

Features of the GSL Series:

- Low noise level thanks to the low rotor speed, inclined cut, and sound-insulated hopper in a multi-layer sandwich design

- Powerful and efficient drive using branded gearbox

- Easy maintenance, cleaning, and blade replacement

The slow-speed granulators of the GSL 180 Series are equipped with a closed rotor with a diameter of 180 mm. The machines are available in working widths from 120 mm to 430 mm.

The rotor consists of individual discs which are directly coupled to the helical bevel gearbox via an oversized drive shaft. This ensures efficient and low-maintenance power transmission.

The material to be granulated can be fed manually, via conveyor belt, or by robot through a generously sized, soundproofed hopper with sandwich construction. As standard, the granulator is mounted on a low base frame with swivel castors. Discharge is via an extraction tray, inserted below the screen, with a pipe connection for a suction conveyor.

Rbsdpfx Adoiy D Szj Tjt

Applications

The slow-speed granulators of the GSL 180 Series are specially designed for the granulation of sprues from injection moulding and blow moulding processes. Thanks to easy access, colour and material changes can be carried out quickly. The low rotor speed also enables the processing of both soft and hard materials and ensures high material quality with minimal fine dust content.

Mali oglas

Buchholz in der Nordheide

Buchholz in der Nordheide

881 km

Stroj za drobljenje

ZERMAGSL 180/300

Klic

Stanje: novo, Leto izdelave: 2025, Slow-speed beside-the-press granulator

Rotor diameter (mm): 180

Rotor width (mm): 300

Rotor speed (rpm): 150

Drive power (kW): 4

Number of rotor knives: 30

Number of stator knives: 2

Screen perforation (mm): >5

Redpst Aam Hjfx Ad Tebt

Weight approx. (kg): 180

The slow-speed beside-the-press granulators of the GSL 180 series feature a rotor diameter of 180 mm and working widths ranging from 120 to 430 mm. The rotor is directly driven by a gear motor. The low rotor speed ensures a pleasant noise level and optimal regrind quality. The special rotor knives can be resharpened multiple times, eliminating the need for complex adjustment work. The granulators are loaded via a noise-reducing sandwich-design feed hopper. Depending on the application, the machines can be equipped with different hopper variants. Optional low and high base frames are available. The regrind is extracted accordingly or collected in bags or a plastic container. Easy and quick maintenance is ensured via the Quick Snap quick-release system, which allows optimal accessibility.

Mali oglas

Buchholz in der Nordheide

Buchholz in der Nordheide

881 km

Rezalni mlin

ZERMAGSL 300/600

Klic

Leto izdelave: 2025, Stanje: novo, Slow-speed beside-the-press granulator GSL 300

Rotor diameter (mm): 300

Rotor width (mm): 600

Rotor speed (min⁻¹): 150

Drive (kW): 11

Number of rotor blades: 48

Number of stator blades: 2

Screen perforation (mm): > 6

Weight approx. (kg): 950

The slow-speed beside-the-press granulators of the GSL series are primarily used in injection moulding and blow moulding applications for inline size reduction of sprues and defective parts. With various hopper and extraction systems, these machines can be flexibly integrated into existing setups.

GSL 300 models are also suitable as central granulators for lower throughput rates.

Highlights of the GSL series:

- Low noise levels due to the rotor’s low rotational speed, angled cutting action, and multi-layer sandwich construction of the sound-insulated feed hopper

- Powerful and efficient drive using branded gearboxes

- Easy maintenance, cleaning, and blade changes

The slow-speed GSL 300 series granulators feature a 300 mm rotor diameter and working widths of 400 mm, 600 mm, and 800 mm. The rotor is directly driven via a geared motor with a bevel gear, ensuring efficient and low-maintenance power transmission and enabling the processing of demanding materials.

The low rotor speed results in reduced noise emissions and a low-dust granulate. The special rotor blades can be reground several times, and complex adjustment work is not required. The "Quick Snap" quick-release system ensures easy and rapid maintenance access.

Material is fed into the mill via a noise-reducing hopper with a sandwich-type construction. Depending on application requirements, the machines can be fitted with various hopper versions. The final material size is determined by the screen perforation, with the screen located beneath the cutting chamber. The high-quality regrind produced is extracted or collected in bags or plastic containers.

Optional low and high base frames are available.

Rbjdsi Hpf Njpfx Ad Tot

Applications

The slow-speed GSL 300 series granulators are suitable for the size reduction of process scrap as well as large-area parts or hollow bodies. Another area of application is use as a central granulator with lower throughput rates. The robust design and high torque of the GSL 300 series also allow for the reduction of thick-walled parts.

Mali oglas

Buchholz in der Nordheide

Buchholz in der Nordheide

881 km

Drobilnik z eno gredjo

ZermaGST 400/600

Klic

Stanje: novo, Leto izdelave: 2025, Funkcionalnost: popolnoma funkcionalen, skupna masa: 2.000 kg, premer rotorja: 400 mm, število rezil: 6, dolžina rotorja: 600 mm, širina rotorja: 400 mm, moč: 22 kW (29,91 KM), širina odprtine za polnjenje: 490 mm, dolžina polnilne odprtine: 590 mm, trajanje garancije: 12 meseci, vhodna napetost: 400 V, The compact inline granulators of the GST series are suitable for use in injection molding and blow molding operations. They are ideal for recycling, for example, voluminous parts such as bottles, cans, crates, sprues, and injection-molded components. Thanks to their low feed height, the machines can be easily loaded with material by hand or with a small conveyor belt. Low noise emissions and a compact footprint make the GST series the perfect solution for inline size reduction.

All GST series machines feature a compact, sound-insulated machine housing and a sound-dampened feed hopper. The feed hopper can be opened and closed using a gas strut. These compact granulators are available with two rotor diameters (250 mm, 400 mm) and rotor widths from 300 to 1000 mm. The smaller models are equipped with an open F-rotor, while the larger machines feature the heavier-duty S-rotor. The curved back wall of the cutting chamber ensures aggressive material intake and prevents material blockages. Thanks to the modular design, the granulator can be easily expanded with further options, such as replaceable wear plates. As with all ZERMA granulators, rotor and stator knives can be adjusted outside the machine, minimizing downtime during maintenance. An adjustment gauge is included. The control cabinet is mounted externally on the sound enclosure, with all wiring routed internally.

Rotor diameter (mm): 400

Rotor width (mm): 600

Drive (kW): 22

Rotor knives (rows): 3 x 2

Stator knives (rows): 2

Screen hole diameter (mm): > 6

Rsdjvgncujpfx Ad Tobt

Cutting chamber (mm x mm): 400 x 600

Weight (approx. kg): 2000

Znak zaupanja

Prodajalci, certificirani pri Machineseeker

Mali oglas

Buchholz in der Nordheide

Buchholz in der Nordheide

881 km

Počasno delujoči rezalni mlin

ZERMAGSL 300/800

Klic

Leto izdelave: 2025, Stanje: novo, Direct drive via geared motor

No adjustment work required thanks to special rotor knives

Easy accessibility for maintenance and cleaning

Low noise emissions and low-dust granulate

thanks to slow rotor speed

Universally applicable with numerous options

Rotor diameter (mm): 300

Rotor width (mm): 800

Rotor speed (rpm): 150

Drive power (kW): 18.5

Number of rotor knives: 66

Number of stator knives: 2

Screen perforation (mm): > 6

Weight approx. (kg): 1100

Rodpon Hqv Djfx Ad Tobt

Mali oglas

Buchholz in der Nordheide

Buchholz in der Nordheide

881 km

Hitri granulator

ZERMAGST 250/600

Klic

Leto izdelave: 2025, Stanje: novo, Reduction of large-volume blow-molded parts as well as start and end pieces

The best features of the proven GST and GSC series have been combined in a compact redesign, with particular emphasis on weight, handling, and energy efficiency. These compact granulators come fully soundproofed, resulting in extremely quiet operation. The granulators are available with a rotor diameter of 250 mm and widths of 300, 450, or 600 mm. The curved rear wall of the cutting chamber provides aggressive material intake and prevents material blockages. As with all ZERMA granulators, rotor and stator knives can be adjusted outside the machine to minimize downtime during maintenance.

The highly tangential, curved rear wall of the cutting chamber, combined with the aggressive open rotor design, ensures reliable material intake and minimizes the risk of clogging.

These compact granulators are suitable for use in blow molding operations. They are ideal for recycling large-volume items such as bottles, canisters, and crates. Thanks to the low feed height, material can easily be fed manually or via a small conveyor belt. The low noise emission and compact footprint make this granulator a perfect solution for inline size reduction.

Optional rear wall with elevated stator knife M version:

The feed method with an elevated stator knife is better suited for thicker and more compact parts, such as injection-molded parts, profiles, and sheets. The cutting geometry and reduced rotor aggressiveness result in high-quality regrind, regardless of material type or shape, including injection-molded parts, profiles, sheets, etc.

Control system and control cabinet:

The integrated control system and operator console not only meet all current safety regulations but can also be adapted to specific requirements. Furthermore, peripherals such as feed conveyors, metal detection systems, and discharge systems can be seamlessly integrated into the machine’s control system. For improved efficiency, an optional intelligent energy-saving function is available, which reduces power consumption during idle periods and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW, and 400 cyclone

Rbodpsp Sr Iajfx Ad Tet

Rotor diameter (mm): 250

Rotor width (mm): 600

Drive (kW): 11

Number of rotor knives: 3 x 2

Number of stator knives: 2

Screen hole diameter (mm): >6

Weight approx. (kg): 1450

Feed opening (mm): 380 x 600

Feed opening M version option (mm): 295 x 600

Mali oglas

Buchholz in der Nordheide

Buchholz in der Nordheide

881 km

Hitri granulator

ZERMAGST 250/300

Klic

Leto izdelave: 2025, Stanje: novo, Size reduction of large-volume blow-moulded parts as well as start and end pieces

Rbsdpfxep Sr Ano Ad Tjt

In a compact redesign, the best features of the proven GST and GSC series have been integrated, with particular emphasis on weight, handling, and energy efficiency. These compact granulators are equipped with complete sound insulation, resulting in extremely quiet operation. The granulators are available with a 250 mm rotor diameter and widths of 300, 450, and 600 mm. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material blockages. As with all ZERMA granulators, rotor and stator knives can be adjusted outside of the machine to minimize maintenance downtime.

The strongly tangential, curved rear wall of the cutting chamber, in combination with the aggressive open rotor design, ensures reliable material feeding and minimizes the risk of blockages. These compact granulators are suitable for use in blow moulding operations and are ideal for recycling large items such as bottles, canisters, crates, etc. The low infeed height allows the machines to be easily loaded by hand or with a small conveyor belt. Low noise emissions and minimal footprint make the granulator the perfect solution for inline size reduction applications.

Optional rear wall with elevated stator knife – M Version:

The feeding method with a higher stator knife is better suited for thicker-walled and more compact parts such as injection-moulded parts, profiles, sheets, etc. Due to the cutting geometry and reduced aggressiveness of the rotor, the machine produces high-quality regrind regardless of the material type or shape, such as injection-moulded parts, profiles, sheets, etc.

Control system and control cabinet:

The integrated control and operation console not only complies with all applicable safety regulations but can also be customized to meet specific requirements. Additionally, peripheral devices such as feed conveyors, metal detection, and discharge systems can be seamlessly integrated into the machine’s control system. For enhanced efficiency, an optional intelligent energy-saving function is available, which reduces power consumption during idle periods and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW, and 400 cyclones.

Rotor diameter (mm): 250

Rotor width (mm): 300

Drive (kW): 7.5

Number of rotor knives: 3 x 1

Number of stator knives: 2

Screen perforation (mm): > 6

Weight approx. (kg): 950

Feed opening (mm): 380 x 300

Feed opening option for M version (mm): 295 x 300

Mali oglas

Buchholz in der Nordheide

Buchholz in der Nordheide

882 km

Stroj za drobljenje

ZermaGST 250/450

Klic

Stanje: novo, Leto izdelave: 2024, Optimization of an established concept.

Rsdet Aagaopfx Ad Tsbt

Shredding of large-volume blow-molded parts as well as start and end pieces

In a compact redesign, the best features of the proven GST and GSC series were integrated, with a particular focus on weight, handling, and energy efficiency. These compact granulators are fully soundproofed, resulting in extremely quiet operation. The granulators are available with a 250 mm rotor diameter and widths of 300, 450, and 600 mm. The contoured rear wall of the cutting chamber ensures aggressive material intake and prevents blockages. As with all ZERMA granulators, both rotor and stator knives are adjustable outside the machine, which reduces downtime during maintenance.

The highly tangential, curved rear wall of the cutting chamber, in combination with the aggressive open rotor design, guarantees reliable material intake and minimizes the risk of blockages.

The compact granulators are suitable for use in blow molding operations. They are ideal for recycling large and voluminous parts such as bottles, canisters, and crates. Thanks to the low feeding height, the machines can be easily loaded by hand or with a small conveyor belt. Their low noise emission and small footprint make these granulators a perfect solution for inline shredding.

98T8Mrx

Optional rear wall with elevated stator knife M version:

The intake method with an elevated stator knife is better suited for thicker-walled and more compact parts, such as injection molded parts, profiles, sheets, etc. Due to the cutting geometry and the lower aggressiveness of the rotor, high-quality regrind is achieved regardless of material type or shape, such as injection molded components, profiles, sheets, etc.

Control system and electrical cabinet:

The integrated control system and operator console not only comply with all applicable safety regulations, but can also be adapted to specific requirements. Additionally, peripherals such as feed conveyors, metal detectors, and discharge systems can be seamlessly integrated into the machine’s control system. For improved efficiency, an optional intelligent energy-saving feature is available, which reduces power consumption during idle times and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW, and 400 cyclone

Rotor diameter (mm): 250

Rotor width (mm): 450

Drive (kW): 7.5

Quantity of rotor knives: 3 x 2

Quantity of stator knives: 2

Screen hole size (mm): > 6

Weight approx. (kg): 700

Feed opening (mm): 380 x 450

Feed opening option M version (mm): 295 x 450

Olajšamo vam iskanje: "zerma granulator"

Nove ponudbe prejmete takoj in brezplačno po e-pošti.

Iskalno nalogo lahko kadar koli preprosto končate.

Rabljeni Zerma Granulator (52)

Zdaj preiščite celoten Machineseeker z več kot 200.000 rabljenimi stroji.Brskajte po najbolj priljubljenih poimenovanjih strojev:

Izvedite več zdaj

+44 20 806 810 84

+44 20 806 810 84

Objavite oglas zdaj

*na oglas/mesec