Hitri granulatorZERMA

GST 250/600

Hitri granulator

ZERMA

GST 250/600

Začetna cena brez DDV

19.400 €

Leto izdelave

2025

Stanje

Novo

Lokacija

Buchholz in der Nordheide

Prikaži slike

Prikaži karto

Podatki o stroju

Cena in lokacija

Začetna cena brez DDV

19.400 €

- Lokacija:

- Vaenser Weg 12, 21244 Buchholz in der Nordheide, Deutschland

Klic

Podrobnosti ponudbe

- ID ponudbe:

- A13548352

- Nazadnje posodobljeno:

- dne 03.05.2025

Opis

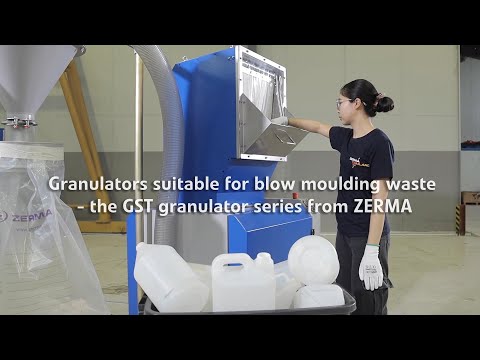

Reduction of large-volume blow-molded parts as well as start and end pieces

Nsdpfx Ajp Sr Iaebbokt

The best features of the proven GST and GSC series have been combined in a compact redesign, with particular emphasis on weight, handling, and energy efficiency. These compact granulators come fully soundproofed, resulting in extremely quiet operation. The granulators are available with a rotor diameter of 250 mm and widths of 300, 450, or 600 mm. The curved rear wall of the cutting chamber provides aggressive material intake and prevents material blockages. As with all ZERMA granulators, rotor and stator knives can be adjusted outside the machine to minimize downtime during maintenance.

The highly tangential, curved rear wall of the cutting chamber, combined with the aggressive open rotor design, ensures reliable material intake and minimizes the risk of clogging.

These compact granulators are suitable for use in blow molding operations. They are ideal for recycling large-volume items such as bottles, canisters, and crates. Thanks to the low feed height, material can easily be fed manually or via a small conveyor belt. The low noise emission and compact footprint make this granulator a perfect solution for inline size reduction.

Optional rear wall with elevated stator knife M version:

The feed method with an elevated stator knife is better suited for thicker and more compact parts, such as injection-molded parts, profiles, and sheets. The cutting geometry and reduced rotor aggressiveness result in high-quality regrind, regardless of material type or shape, including injection-molded parts, profiles, sheets, etc.

Control system and control cabinet:

The integrated control system and operator console not only meet all current safety regulations but can also be adapted to specific requirements. Furthermore, peripherals such as feed conveyors, metal detection systems, and discharge systems can be seamlessly integrated into the machine’s control system. For improved efficiency, an optional intelligent energy-saving function is available, which reduces power consumption during idle periods and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW, and 400 cyclone

Rotor diameter (mm): 250

Rotor width (mm): 600

Drive (kW): 11

Number of rotor knives: 3 x 2

Number of stator knives: 2

Screen hole diameter (mm): >6

Weight approx. (kg): 1450

Feed opening (mm): 380 x 600

Feed opening M version option (mm): 295 x 600

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Nsdpfx Ajp Sr Iaebbokt

The best features of the proven GST and GSC series have been combined in a compact redesign, with particular emphasis on weight, handling, and energy efficiency. These compact granulators come fully soundproofed, resulting in extremely quiet operation. The granulators are available with a rotor diameter of 250 mm and widths of 300, 450, or 600 mm. The curved rear wall of the cutting chamber provides aggressive material intake and prevents material blockages. As with all ZERMA granulators, rotor and stator knives can be adjusted outside the machine to minimize downtime during maintenance.

The highly tangential, curved rear wall of the cutting chamber, combined with the aggressive open rotor design, ensures reliable material intake and minimizes the risk of clogging.

These compact granulators are suitable for use in blow molding operations. They are ideal for recycling large-volume items such as bottles, canisters, and crates. Thanks to the low feed height, material can easily be fed manually or via a small conveyor belt. The low noise emission and compact footprint make this granulator a perfect solution for inline size reduction.

Optional rear wall with elevated stator knife M version:

The feed method with an elevated stator knife is better suited for thicker and more compact parts, such as injection-molded parts, profiles, and sheets. The cutting geometry and reduced rotor aggressiveness result in high-quality regrind, regardless of material type or shape, including injection-molded parts, profiles, sheets, etc.

Control system and control cabinet:

The integrated control system and operator console not only meet all current safety regulations but can also be adapted to specific requirements. Furthermore, peripherals such as feed conveyors, metal detection systems, and discharge systems can be seamlessly integrated into the machine’s control system. For improved efficiency, an optional intelligent energy-saving function is available, which reduces power consumption during idle periods and can automatically start and stop the system based on the status of upstream machines.

Standard configuration with blower, power consumption 0.75 kW, and 400 cyclone

Rotor diameter (mm): 250

Rotor width (mm): 600

Drive (kW): 11

Number of rotor knives: 3 x 2

Number of stator knives: 2

Screen hole diameter (mm): >6

Weight approx. (kg): 1450

Feed opening (mm): 380 x 600

Feed opening M version option (mm): 295 x 600

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Ponudnik

Opomba: Brezplačno se registrirajte ali prijavite, za dostop do vseh informacij.

Registriran od: 2023

Pošlji zahtevo

Telefon & Faks

+49 4181 ... oglasi

Ti oglasi bi vas prav tako lahko zanimali.

Mali oglas

Deitingen

Deitingen

575 km

Orodje brusilni stroj

W. ScherrerSB 10

W. ScherrerSB 10

Mali oglas

Mindelheim

Mindelheim

400 km

Dvojno poševna tračna žaga

MIOTALS 255 DG

MIOTALS 255 DG

Mali oglas

Berlin

Berlin

706 km

Pick-up kombi

PEUGEOTBoxer Euro 5 3,80m

PEUGEOTBoxer Euro 5 3,80m

Mali oglas

Zuzenhausen

Zuzenhausen

581 km

Shredder

ZERMAZRS

ZERMAZRS

Mali oglas

Velbert

Velbert

819 km

Stroj za zavezovanje trakov

CyklopXZE-311

CyklopXZE-311

Mali oglas

Sinsheim

Sinsheim

569 km

Rezalni mlin

NEUE HERBOLDSM 300/500-S3-3 EDELSTAHL/STAINLESS STEE

NEUE HERBOLDSM 300/500-S3-3 EDELSTAHL/STAINLESS STEE

Mali oglas

Zuzenhausen

Zuzenhausen

581 km

Stranski mlini

ZERMAGSL 300

ZERMAGSL 300

Mali oglas

Petrovče

Petrovče

19 km

Drobilnik

Robust¸Reuser SD 700/22 kW

Robust¸Reuser SD 700/22 kW

Mali oglas

Berlin

Berlin

713 km

Rotacijski filter

SEITZ ENZINGER NOLLVACUBLOC

SEITZ ENZINGER NOLLVACUBLOC

Mali oglas

Concordia Sagittaria

Concordia Sagittaria

174 km

Stroj za tračno žaganje THREE-PHASE

NEBESTM 275

NEBESTM 275

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake