Hitri granulatorZERMA

GST 250/450

Hitri granulator

ZERMA

GST 250/450

Začetna cena brez DDV

18.100 €

Leto izdelave

2024

Stanje

Novo

Lokacija

Brahlstorf

Prikaži slike

Prikaži karto

Podatki o stroju

Cena in lokacija

Začetna cena brez DDV

18.100 €

- Lokacija:

- Schützenstraße 7, 19273 Brahlstorf, Deutschland

Klic

Podrobnosti ponudbe

- ID ponudbe:

- A13548343

- Nazadnje posodobljeno:

- dne 03.05.2025

Opis

Optimization of an established concept.

Ppsdpfxsp Sr H Do Aczsl

Shredding of large-volume blow-molded parts as well as start and end pieces

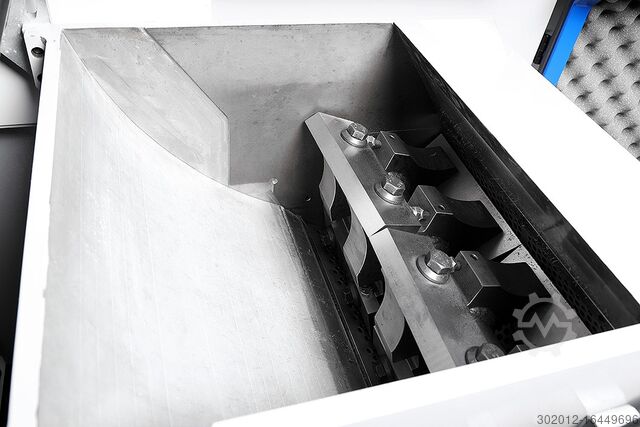

The compact redesign integrates the best features of the proven GST and GSC series, with a particular focus on weight, handling, and energy efficiency. These compact granulators are equipped with complete sound insulation, resulting in ultra-quiet operation. The granulators are available with a 250 mm rotor diameter and widths of 300, 450, and up to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material blockages. As with all ZERMA granulators, both rotor and stator knives can be adjusted outside the machine, minimizing maintenance downtime.

The pronounced tangential, curved rear wall of the cutting chamber, combined with the aggressive, open rotor design, ensures reliable material feeding and minimizes the risk of blockages.

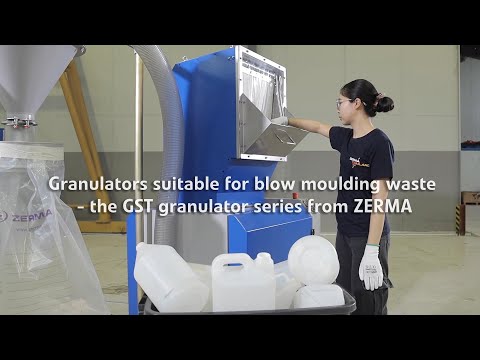

These compact granulators are suitable for blow-molding operations and ideal for recycling large parts such as bottles, jerrycans, and crates. Thanks to their low feed height, they can be easily loaded by hand or with a small conveyor belt. Low noise emissions and a small footprint make these granulators the perfect solution for inline granulation.

Optional rear wall with raised stator knife (M version):

The feed method with a higher-positioned stator knife is especially suited for thick-walled and more compact parts, such as injection-molded components, profiles, sheets, etc. The cutting geometry and the rotor’s reduced aggressiveness result in high-quality regrind, regardless of the material’s type or form (e.g. injection-molded parts, profiles, sheets, etc.).

Control system and control cabinet:

The integrated control system and operator console fully comply with all applicable safety regulations and can be tailored to specific requirements. In addition, peripheral equipment such as infeed conveyors, metal detection systems, and discharge units can be seamlessly integrated into the machine’s control system. An optional intelligent energy-saving function is available to improve efficiency, automatically reducing power consumption during idle times and starting or stopping the system based on the status of upstream machines.

Standard configuration with blower, 0.75 kW power consumption, and 400 cyclone

Rotor diameter (mm): 250

Rotor width (mm): 450

Drive (kW): 7.5

Number of rotor knives: 3 x 2

Number of stator knives: 2

Screen perforation (mm): > 6

Weight approx. (kg): 700

Feed opening (mm): 380 x 450

Feed opening for M version option (mm): 295 x 450

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Ppsdpfxsp Sr H Do Aczsl

Shredding of large-volume blow-molded parts as well as start and end pieces

The compact redesign integrates the best features of the proven GST and GSC series, with a particular focus on weight, handling, and energy efficiency. These compact granulators are equipped with complete sound insulation, resulting in ultra-quiet operation. The granulators are available with a 250 mm rotor diameter and widths of 300, 450, and up to 600 mm. The curved rear wall of the cutting chamber ensures aggressive material intake and prevents material blockages. As with all ZERMA granulators, both rotor and stator knives can be adjusted outside the machine, minimizing maintenance downtime.

The pronounced tangential, curved rear wall of the cutting chamber, combined with the aggressive, open rotor design, ensures reliable material feeding and minimizes the risk of blockages.

These compact granulators are suitable for blow-molding operations and ideal for recycling large parts such as bottles, jerrycans, and crates. Thanks to their low feed height, they can be easily loaded by hand or with a small conveyor belt. Low noise emissions and a small footprint make these granulators the perfect solution for inline granulation.

Optional rear wall with raised stator knife (M version):

The feed method with a higher-positioned stator knife is especially suited for thick-walled and more compact parts, such as injection-molded components, profiles, sheets, etc. The cutting geometry and the rotor’s reduced aggressiveness result in high-quality regrind, regardless of the material’s type or form (e.g. injection-molded parts, profiles, sheets, etc.).

Control system and control cabinet:

The integrated control system and operator console fully comply with all applicable safety regulations and can be tailored to specific requirements. In addition, peripheral equipment such as infeed conveyors, metal detection systems, and discharge units can be seamlessly integrated into the machine’s control system. An optional intelligent energy-saving function is available to improve efficiency, automatically reducing power consumption during idle times and starting or stopping the system based on the status of upstream machines.

Standard configuration with blower, 0.75 kW power consumption, and 400 cyclone

Rotor diameter (mm): 250

Rotor width (mm): 450

Drive (kW): 7.5

Number of rotor knives: 3 x 2

Number of stator knives: 2

Screen perforation (mm): > 6

Weight approx. (kg): 700

Feed opening (mm): 380 x 450

Feed opening for M version option (mm): 295 x 450

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Ponudnik

Opomba: Brezplačno se registrirajte ali prijavite, za dostop do vseh informacij.

Registriran od: 2023

Pošlji zahtevo

Telefon & Faks

+49 4181 ... oglasi

Ti oglasi bi vas prav tako lahko zanimali.

Mali oglas

Buchholz in der Nordheide

Buchholz in der Nordheide

882 km

Stroj za drobljenje

ZermaGST 250/450

ZermaGST 250/450

Mali oglas

Zuzenhausen

Zuzenhausen

581 km

Stranski mlini

ZERMAGSL 300

ZERMAGSL 300

Mali oglas

Buchholz in der Nordheide

Buchholz in der Nordheide

881 km

ZERMA GST250/450 granulator z votlim ohišjem

ZERMAGST 250/450

ZERMAGST 250/450

Mali oglas

Sieradz

Sieradz

666 km

Generator

ProtonOasis 1

ProtonOasis 1

Mali oglas

Zuzenhausen

Zuzenhausen

581 km

Rezalni mlini

ZERMARohr- und Profilschneidmühle GSP

ZERMARohr- und Profilschneidmühle GSP

Mali oglas

Klundert

Klundert

980 km

Generator

John DeereStamford 42.5kVA

John DeereStamford 42.5kVA

Mali oglas

Erftstadt

Erftstadt

796 km

Stroj za polnjenje in zapiranje vrečk

alpha-pack GmbHModell DEDAPHS-140S

alpha-pack GmbHModell DEDAPHS-140S

Mali oglas

Berlin

Berlin

713 km

Granulator

Tria80-40 TE-SL

Tria80-40 TE-SL

Mali oglas

Berlin

Berlin

713 km

Krčilni predor

Quick-packTTN50

Quick-packTTN50

Mali oglas

Sottrum

Sottrum

880 km

Traktor

JCBFastrac 4x4 Mulag Front Heck Mäher 8632 Stunden

JCBFastrac 4x4 Mulag Front Heck Mäher 8632 Stunden

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake