Obdelovalni centri z ravno ali mrežasto mizo nakup rabljenega (327)

Razvrsti rezultate

- Najnižja cena Najvišja cena

- Najnovejši oglasi Najstarejši oglasi

- Najkrajša razdalja Največja razdalja

- Najnovejše leto izdelave Najstarejše leto izdelave

- Zadnja posodobitev Najstarejša posodobitev

- Proizvajalci od A do Ž Proizvajalec od Z do A

- Pomembnost

- Najnižja cena

- Cena

- Najvišja cena

- Cena

- Najnovejši oglasi

- Datum objave

- Najstarejši oglasi

- Datum objave

- Najkrajša razdalja

- Razdalja

- Največja razdalja

- Razdalja

- Najnovejše leto izdelave

- Leto izdelave

- Najstarejše leto izdelave

- Leto izdelave

- Zadnja posodobitev

- Nazadnje posodobljeno

- Najstarejša posodobitev

- Nazadnje posodobljeno

- Proizvajalci od A do Ž

- Proizvajalec

- Proizvajalec od Z do A

- Proizvajalec

- Oznaka od A do Ž

- Oznaka

- Oznaka od Z do A

- Oznaka

- Model od A do Ž

- Model

- Model od Z do A

- Model

- Najnižja referenca

- referenca

- Najvišja referenca

- referenca

- Najkrajši obratovalni čas

- Obratovalni čas

- Najdaljši čas obratovanja

- Obratovalni čas

- Pomembnost

- Pomembnost

Stroji za obdelavo lesa CNC obdelovalni centri za les Obdelovalni centri z ravno ali mrežasto mizo

Dražba

Dražba končana

Lombardia

Lombardia

413 km

CNC obdelovalni center za les

MTCHMT-FR 3020

Stanje: novo, Leto izdelave: 2024, Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 3.000 mm, pomik osi Y: 2.000 mm, pomik po osi Z: 200 mm, največja hitrost vretena: 18.000 obr/min, TECHNICAL DETAILS

Travel Range X / Y / Z: 3,000 / 2,000 / 200 mm

Accuracy: 0.01 mm

Spindle

Spindle Power: 3.0 kW

Ijdpjwgbtlsfx Ah Asbf

Spindle Speed: 0 - 18,000 rpm, variable

Spindle Diameter: 3.175 - 12.7 mm

Spindle Cooling: Air-cooled

Working Area and Equipment

Maximum Material Height: 120 mm

Worktable Size: 3,000 x 2,000 mm

Vacuum Table: 5.5 kW dual-stage, divided into 6 zones

Felt Mat Thickness: 4.5 mm

Plotter Equipment

1st Head: Electrospindle, 380V, 5.5 kW, water-cooled

2nd Head: Electric oscillating knife

3rd Head: Roll tool

EQUIPMENT

- PC including machine control software and Ethernet interface

- Supported file formats: Vector formats, DXF, G-Code

- Camera for print mark recognition

- Extraction unit with dual filter and 3.0 kW motor

- Extraction pipe and collector for the spindle

Mali oglas

Willroth

Willroth

739 km

Obdelovalni center

BIESSERover A FT 2243

Klic

Stanje: zelo dobro (rabljeno), Leto izdelave: 2016, Funkcionalnost: popolnoma funkcionalen, Rabljen BIESSE Rover A

- Nesting CNC

- Letnik: 2016

- Na voljo od novembra 2025

- Dodatne fotografije in video so na voljo

Ibodpoxhcndefx Ah Aof

Dražba

Dražba končana

Sachsen

Sachsen

609 km

CNC obdelovalni center

SCMRecord 240

Stanje: pripravljen za uporabo (rabljen), Leto izdelave: 2000, Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 6.000 mm, pomik osi Y: 1.250 mm, pomik po osi Z: 300 mm, največja hitrost vretena: 18.000 obr/min, število mest v zalogovniku orodij: 36, S podajo ponudbe se zavezujete, da boste napravo pravočasno prevzeli najkasneje do 15.09.2025!

TEHNIČNE PODROBNOSTI

Hodi

Hod v osi X: 6.000 mm

Hod v osi Y: 1.250 mm

Hod v osi Z: 300 mm

Podatki o vretenu

Hitrost vrtenja: 900 – 18.000 min⁻¹

Moč vretena: 11 kW

Sistem vpenjanja orodij: HSK-F63

Podatki o orodju in mizi

Konzolna miza: 10 konzol / prečk

Sesalci: cca 20 kos

Moč vakuumske črpalke: 250 m³/h

Osi: 4 (vključno s C-osjo)

Mesta za menjavo orodij: 36

PODROBNOSTI STROJA

Iodpfx Ahjw I Ttrj Asbf

Krmiljenje: PC-krmiljenje

Programska oprema: SCM XILOG

Teža: cca 7.500 kg

OPREMA

Menjalnik orodij z vrtljivim magazinom

Magazin za orodja TOOL ROOM

2 kos škatlasti agregat (dodatni horizontalni agregat)

Pomoč pri pozicioniranju

Laserski projektor

Varnostna oprema: odbijač

Ročni terminal

Pomožna podpora za obdelovanec

Samodejno mazanje

Oznaka skladnosti CE

Opomba: Orodja za obdelavo niso vključena v obseg prodaje in dobave.

Izvedite več zdaj

+44 20 806 810 84

+44 20 806 810 84

Objavite oglas zdaj

*na oglas/mesec

Mali oglas

Zona Industriale "scerne"

Zona Industriale "scerne"

398 km

CNC OBDELOVALNI CENTER ZA OBREZOVANJE ROBOV

HOMAGBAZ 20/50/14/G

Klic

Stanje: zelo dobro (rabljeno), Delovno središče z enoto za robno lepljenje za ravne in ukrivljene plošče

- 4-osni elektro vreteno z vpetjem HSK F63, za natančne in vsestranske obdelave

- Avtomatski revolverski magazin za orodja z 12 mesti, za hitro menjavo orodja

- Integrirana vrtalna glava, idealna za vrtanje v različne materiale

Ibedpfx Aolpf E Ujh Aof

- Enota za robno lepljenje za natančno nanašanje robnega traku na ravne in ukrivljene plošče

- Magazinski sistem za robne trakove s 3 pozicijami, za učinkovito upravljanje različnih vrst trakov

- Vakuumska črpalka za varno fiksiranje plošče med obdelavo

Mali oglas

Libřice

Libřice

466 km

CNC obdelovalni center FORMAT4 creator 950

FelderCreator 950 Premium

Klic

Stanje: skoraj kot novo (rabljeno), Leto izdelave: 2022, Felder Creator 950 Premium is a high-precision CNC machining center designed for efficient and flexible production of wooden components. Thanks to its robust construction and modern technologies, it enables fast and precise milling, drilling, and grooving. The machine is ideal for furniture and interior element manufacturers seeking a reliable and powerful CNC solution.

Technical information:

Machining field: X = 3500 mm, Y = 950 mm, Z = 80 mm

Axis positioning speed: Depends on the selected safety system

Milling spindle: 12 kW (S6) HSK F63, 24,000 rpm

Safety features: CE certification, optical operation indicator

Ijdpfx Ahjv I Syte Ajbf

Power supply: 3 x 400V / 50 Hz

Software: WoodFlash – CNC module, tool database, program editor

Machine configuration:

Through-feed CNC center with X-direction clamp drive and fixed gantry construction in the Y direction

Automatic central lubrication

Pneumatic pressure rollers for improved workpiece fixation

Height-adjustable worktable for optimal handling

Dowel insertion unit with precise glue dosing

Odkrijte več rabljenih strojev

Mali oglas

Radviliškis

Radviliškis

1.229 km

Obdelovalni Center

HomagOptimat baz 41/30k event

Klic

Stanje: pripravljen za uporabo (rabljen), Leto izdelave: 2003, Funkcionalnost: popolnoma funkcionalen, številka stroja/vozila: 0-201-24-6821, Popolnoma funkcionalni 4-osni CNC obdelovalni center Homag BAZ 41, pripravljen za obratovanje. Odličen za proizvodnjo plošč, MDF, lesa in vrat. Velikost mize: 3000 mm x 1300 mm. Vključuje 3 obdelovalne enote (agregate). Stroj je v dobrem delovnem stanju in ga je možno preizkusiti na lokaciji.

Iedpfjxt Tzlox Ah Ajbf

Mali oglas

Hermaringen

Hermaringen

448 km

Obdelovalni center

MAKABC 150t compakt

Klic

Stanje: zelo dobro (rabljeno), Leto izdelave: 2015, Funkcionalnost: popolnoma funkcionalen, MAKA BC 150t compact, used machine

5-axis CNC machining center for processing aluminum and plastic.

Gantry-type bridge construction with 4 columns, 2 x aggregate carriers.

Technical Data:

Working areas in 5-axis operation, with tool Ø 160 mm / tool length 160 mm:

2 x each:

Y-axis: 1,500 mm

X-axis: 2,500 mm

Z-axis: 650 mm (with 180 mm fixture height)

Linkable tables for machining large parts.

Extended travel stroke for loading and unloading.

Rapid traverse speed: X-/Y-/Z-axis 60 m/min. Acceleration: 3 m/sec²

Rotary axis 540° / Swivel axis 196° (+/- 98°)

Table design:

- 2 x aluminum surface tables, size 2,500 x 1,500 mm

- Threaded bushings M10 and centering pins in the tabletop

- 3 x vacuum clamping circuits per table

- 3 x pneumatic clamping circuits per table

Milling units:

Isdpfxjtq Hkro Ah Aobf

- 2 universal aggregates for 5-axis milling, with 50° angle head, HSK F63 tool holder, max. power 12.5 kW (S1), infinitely variable speed up to 24,000 rpm, water-cooled milling spindle

- 1 NC height-adjustable chip extraction system per milling unit, with lamella curtain

Tool changer:

- 2 x rotary disc tool magazines with 20 positions each

Control system:

- 1 x Siemens SINUMERIK 840D SL machine control

- 1 x Siemens OP 19 PCU operator panel with 19" display, full keyboard, membrane keypad

- 1 x additional Siemens HT 8 portable handheld operating unit with 7.5" touchscreen, version with manual pulse generator

Safety equipment:

- 1 soundproof enclosure

- 2 automatic loading doors with viewing windows

- Loading and unloading areas safeguarded by light barriers and bumpers on the tables

Measuring probes:

- 2 x 3D radio measuring probes, HSK F63 interface, for automatic changing from the tool magazine

Minimum quantity lubrication:

- 2 minimum quantity lubrication units

- 2 spray nozzles per milling unit, individually controllable via M-function

Table air blow-off system:

- 2 x air knife table blow-off systems for cleaning the tables during traverse out of the machining area (limited in coupled operation)

The machine is installed and can be inspected in 89568 Hermaringen.

Mali oglas

Křečkov

Křečkov

448 km

Obdelovalni center

BUSELLATOOptima C21

Klic

Stanje: zelo dobro (rabljeno), Leto izdelave: 2013, Funkcionalnost: popolnoma funkcionalen, - Working area: 3050x1250mm

- Main spindle: 11/13kW (S1/S6)

Ijdpfx Aowiuz Uoh Aobf

- C-axis

- Drills: 8 vertical, 2+2 horizontal

- Grooving saw

- Tool magazine: 10 positions

Mali oglas

Rosmalen

Rosmalen

935 km

Obdelovalni Center

BIESSERover B G 2231 FT

Klic

Stanje: rabljeno, Leto izdelave: 2014, Biesse Rover B G 2231 FT, komplett mit Be- und Entladesystem

Beschreibung:

Arbeitsbereich X in Y: 3100 x 2205 mm

Flachbett-Tisch

Anzahl Achsen Fräsmotor: 3

Kein Bohraggregat

Werkzeugaufnahme: HSK 63

Wechsler: Feststehend, 21 Plätze

Vakuumpumpen: 2 x 300 m³

Absperrungen

Office-Softwarelizenz

Ein- und Auslauftisch (Beladung mittels Vakuumheber)

Abkehrarm

Einlaufanschlag

B-Solid Presetter

Detaillierte Beschreibung auf Anfrage

Ibsdpow Hf A Rjfx Ah Aef

(Trotz größter Sorgfalt sind alle Änderungen, Irrtümer in den technischen Daten, Preisen und allen Angaben vorbehalten. Keine Garantie auf gedruckte Daten!

Verfügbarkeit vorbehaltlich Zwischenverkauf).

Preise zzgl. Inserierungskosten Machineseeker

Best woodworking machines from the Netherlands Holland

Die besten Holzbearbeitungsmaschinen aus den Niederlanden

De beste gebruikte machines uit Nederland

Mali oglas

Almelo

Almelo

922 km

Obdelovalni center

Danmar Machines BV, ALMELOBudgeCraft “Precision1326”

Klic

Stanje: novo, Leto izdelave: 2025, Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 3.200 mm, pomik osi Y: 1.600 mm, pomik po osi Z: 200 mm, hitro pomikanje X-os: 50 m/min, hitri pomik os Y: 50 m/min, hitri pomik na osi Z: 15 m/min, proizvajalec krmilnikov: LNC-Control, dolžina obdelovanca (maks.): 3.200 mm, širina obdelovanca (maks.): 2.100 mm, višina obdelovanca (maks.): 200 mm, teža obdelovanca (maks.): 1.500 kg, Oprema: vrtilna hitrost brezstopenjsko nastavljiva, BudgeCaft is a manufacturer of high-quality CNC machines.

We design, develop, assemble, and sell CNC machines for businesses and industrial manufacturers.

BEST DEAL

Transport, installation, machine instruction, and CAD/CAM training are provided by Danmar Machines

(languages: Dutch, English, French, Italian, or German). Surcharge depends on location.

• Starter tool kit

• ISO30

• ER32/ER40 collets

• Vacuum pump

• ATC spindle CC 9 kW

• 1 year online CAD/software support/helpdesk (English)

• Standard 12-month factory warranty

Suitable for machining: wood, panel materials, acrylic, PVC, aluminium, foam, plywood, plasterboard, Rockwool, … plastics, …

- 9 kW ATC spindle ISO30 ER32/ER40

- LNC MW control system

- Leadshine servo motors

- Tool changer magazine

- Vacuum table

- Vacuum pump

- High-performance side channel blower, air pump

- Pegasus CadCam software

Custom configurations available

Working area dimensions:

1300 x 2600 mm €31,800

1600 x 3200 mm €37,500

2100 x 3200 mm €41,600

Linear tool magazine with automatic changeover:

10-12-16 tool positions, automatic tool change during machining.

X-axis working area: 2600–3200 mm

Y-axis working area: 1300–1600–2100 mm

Z-axis stroke: 200 mm

Gantry construction: Yes

Milling motor: 9 kW Servo Motor (ATC spindle)

Speed: 1,000–24,000 rpm

X-axis travel: 50 m/min

Y-axis travel: 50 m/min

Z-axis travel: 15 m/min

Mounting: ISO30-ER32-ER40

Software: Pegasus PWoodEntry

Ibsdewc Uadjpfx Ah Asf

Vacuum pump: included

Mali oglas

Libřice

Libřice

466 km

Obdelovalni center Format4 Profit h80

FelderFormat4 Profit h80

Klic

Stanje: skoraj kot novo (rabljeno), Leto izdelave: 2022, The Felder profit H80 is a professional CNC machining center suitable for high-volume furniture production and other woodworking applications. The machine enables precise machining with high speed and efficiency. Thanks to its gantry design and advanced vacuum system, stable and safe processing of even the largest workpieces is ensured.

Technical information:

Machining area: X = 3090 mm, Y = 2100 mm, Z = 85 mm

Power transmission: Rack-and-pinion drive in X and Y axes, ball screw drive in Z axis

Feed rate: X = 25 m/min, Y = 25 m/min, Z = 15 m/min

Vacuum table: 10 vacuum zones with Smart Zoning function

Milling spindle: 12 kW (S6) HSK F63, 24,000 rpm

Power supply: 3 x 400V / 50 Hz

Software: Compact Control – supports ISO Code and WoodFlash

Extraction: Central suction nozzle with slider distribution

Safety features: Light barrier system, optical operating status indicator

Machine features:

Ibjdpfx Asv I Sxpjh Asf

Robust gantry construction with dual drive in the X axis

Fully automated central lubrication for all axes

Control panel with 24" LED display and USB interface

Green Line energy-saving package

Drilling head DH 16 4H 2S – 12 vertical and 4 horizontal spindles

Loading unit with lifting table for efficient handling

Discharge conveyor on the machine’s outfeed side for smooth workpiece removal

Mali oglas

Kežmarok

Kežmarok

525 km

Gnezdenje CNC delovnega centra skozi podajanje

BiesseExcel NBC 712 X1-S

Klic

Stanje: skoraj kot novo (rabljeno), Leto izdelave: 2008, I am selling a through-feed CNC nesting machining center Biesse Excel NBC 712 X1-S, year of manufacture 2008.

Very productive and fast.

Automatic infeed table.

Working area: 3730 x 2200 mm

Ijdpefwvppofx Ah Ajbf

Configuration:

Milling head HSK63, 12 kW, 1,000–24,000 rpm, independent Z-axis with liquid cooling,

with magazine for 8 HSK63 positions.

16+8+4 drilling heads

1 grooving saw D.150mm, 2 positions X/Y

1 revolving electrospindle with cutting unit

Software: BiesseWorks Advanced + Biesse Nest (CD included)

Pumps: 3 pcs BUSCH 3x 300/360 m³/h

Condition: Like new! Fully functional.

Automatic central lubrication and extraction hood system.

Complete with safety barriers, transport elements, and CE compliance points.

CE certificate and full documentation included.

Mali oglas

Hermaringen

Hermaringen

448 km

Obdelovalni center

MAKAECM 27 R

Klic

Stanje: dober (rabljeno), Leto izdelave: 1998, Funkcionalnost: popolnoma funkcionalen, MAKA ECM 27 R

Year of manufacture: 1998

• High-performance CNC machining center for 5-axis operations, ideal for aluminum processing and mold making.

• MAKA ECM 27 R in portal design.

• Equipped with automatic central lubrication system and control cabinet with air-conditioning unit.

• CNC control BWO 900C, 1 MB memory, integrated PC.

• Portable control panel BWO RC 910.

Technical data:

Working areas / working envelope (cube):

With tool length 130 mm and Ø 60 mm

X-axis: 3,000 mm

Y-axis: 2,250 mm

Z-axis: 800 mm (with fixture height 170 mm)

A-axis: 540° (+/- 270°)

B-axis: 200° (+/- 100°)

Rapid traverse speeds:

X/Y axis: 40 m/min

Z axis: 15 m/min

A/B axis: 10,000 °/min

1 pc. milling spindle 11 kW,

Variable spindle speed from 2,000 – 17,000 rpm,

With ceramic bearings and liquid cooling.

Ibsdpfxet Dl U Ee Ah Aof

Tool holder SK 40 with automatic tool changer.

1 pc. chain-type tool magazine for 12 tools up to Ø 160 mm, including 2 positions for angular drilling heads (fixed-position coded), SK40.

1 pc. steel surface table 3,000 x 2,250 mm with T-slots.

1 pc. vacuum pump approx. 140 m³/h, with 250-liter tank.

1 pc. vacuum clamping circuit.

Work safety:

With safety enclosure for the rear of the machine, side access door, cabin open at the top.

Lamella curtain on operator side and safety bumper on the front of the table.

Repairs / refurbishment before delivery:

- Maintenance.

Electrical connection values:

Voltage: 400 V (max. +/- 5%), Frequency: 50 Hz

Rated power: 22.5 kW

Use of an RCD protective device in the machine supply line is not possible.

Operating temperature: 10 – 35° C

Pneumatics: 6 bar, approx. 10 m³/h

No tool holders and machining tools are included in the scope of delivery.

Used machine, sold without any warranty or guarantee.

Optional:

Including installation and commissioning with handover ready for production!

Mali oglas

Jonschwil

Jonschwil

474 km

Obdelovalni center

CNC-STEPRaptor X-SL S-1200 S15

Klic

Stanje: dober (rabljeno), Leto izdelave: 2017, potovalna razdalja osi X: 1.200 mm, pomik osi Y: 1.510 mm, pomik po osi Z: 300 mm, skupna višina: 1.700 mm, skupna dolžina: 2.220 mm, skupna širina: 1.500 mm, širina mize: 1.500 mm, dolžina mize: 1.700 mm, skupna masa: 800 kg, največja hitrost vretena: 24.000 obr/min, Gantry milling machine for processing wood, plastic, and aluminum sheets; complete system including programming workstation PC, touch probe, wireless remote control, Festool extraction station (without vacuum cleaner), CNC software Constructcam-3D and Kinetic-NC.

Ibodpfxjv I Duis Ah Aef

Mali oglas

Eibelstadt

Eibelstadt

545 km

CNC STRUŽNICA

FlexiCAMXL 1530

Klic

Leto izdelave: 2017, Stanje: kot nova (razstavni stroj), Machine Data

• Gantry system with fixed table and moving portal for minimal footprint

• Base frame, bridge, and bridge uprights made of steel, welded in one piece, stress-relieved, and machined

• Main machine assemblies consist of ribbed welded construction, optimized for an ideal stiffness-to-weight ratio as well as vibration damping and high acceleration

• Each machine design is tested and optimized using Finite Element Analysis (FEA) to ensure maximum quality, performance, and safety

• Easily accessible machine table for convenient loading and unloading with a forklift or overhead crane

• Precision ground linear guides with high preload and additional cover strip for optimum chip removal on all axes

• Dual-sided, synchronized drive on the X-axis (gantry drive)

• Rack and pinion drive on X- and Y-axes

• Precision ball screw drive on Z-axis

• Precision planetary gearboxes

• Enclosed cable carrier chains

Iedpfxjflprio Ah Ajbf

• High-quality shielded cable carrier lines

• X-axis working range 3,050 mm

• Y-axis working range 1,550 mm

• Z-clearance 280 mm

• Z-travel 480 mm

• Maximum traverse speed 80 m/min

• Network connection via Ethernet

• Remote maintenance via Internet

• Total weight approx. 4,000 kg

CNC Control

• FlexiCAM ACS Control System Pro

• Powerful industrial CNC control "Made in Germany"

• DIN-ISO 66025 G-code compatible

• Industrial PC with 17" touchscreen monitor as HMI

• User-friendly machine control panel

• Rotary switches for feedrate and spindle speed

• Handheld pendant for setup mode with handwheel, axis & resolution selection, emergency stop button

• Windows keyboard and mouse

• Front USB port

• Ethernet port (RJ45)

• Includes remote maintenance via Internet

• Control and operator panel integrated in control cabinet

Drive Technology

• Digital servo drives with AC servo motors

• High-resolution absolute encoders (17-bit)

• EtherCAT fieldbus

Spindle with Automatic Tool Changer

• Power consumption 10 kW (S1) / 12 kW (S6)

• Speed 2,000 - 24,000 rpm, infinitely programmable

• Ceramic bearings

• Cooling via integrated electric fan

• HSK-63F tool holder

• Max. 26 mm shank or tool diameter

• Temperature monitoring

• Safety check for tool holder in spindle

• Compressed air monitoring

Extraction Device for Automatic Tool Change

• Hose connection 120 mm diameter

• Manual height adjustment

• Pneumatic up/down for tool change

Tool Changer Magazine

• Linear tool changer mounted outside the working area at the rear of the machine

• Prepared for up to 12 tool positions

• HSK-63F / ER40 tool holders included (4x)

Precision Tool Length Sensor

6-zone High-pressure Vacuum Table

• Phenolic resin laminated board (25 mm thickness)

• Zones individually switchable automatically via program or control panel

High-pressure vacuum pump as per customer requirements

4x Pneumatic Stops

Automatic Centralized Lubrication (Grease)

CE Package

Delivery, commissioning & training as agreed

Mali oglas

Timișoara

Timișoara

483 km

Predelovalni center

SCMRecord 132

Klic

Stanje: zelo dobro (rabljeno), SCM Machining Center

Ibodpfxswmxkue Ah Aef

Mali oglas

Cristian

Cristian

813 km

Stiskalnica za lepljene lepljene nosilce

ZOHDING MachineryMHL13000

Klic

Stanje: novo, Leto izdelave: 2025, Funkcionalnost: popolnoma funkcionalen, številka stroja/vozila: NON, potovalna razdalja osi X: 13.000 mm, pomik osi Y: 230 mm, pomik po osi Z: 1.300 mm, Nazwa produktu: Jednostronna pionowa maszyna kwadratowa MHL13000

Maksymalna długość obróbki: 13 000 mm

Maksymalna szerokość obróbki: 1 300 mm

Maksymalna grubość obróbki: 230 mm

Nominalne ciśnienie układu hydraulicznego: 16 MPa

Główny cylinder dociskowy (średnica cylindra x skok): φ100 x 100, 34 szt. (razem 34 cylindry)

Boczny cylinder dociskowy (średnica cylindra x skok): φ50 x 150, 34 szt. (razem 34 cylindry)

Boczny cylinder podnoszący (średnica cylindra x skok): φ63 x 400, 8 szt. (razem 8 cylindrów)

Typ bocznej płyty dociskowej: Jednostronna stopka dociskowa

Iedoxgb Iaspfx Ah Asbf

Moc silnika hydraulicznego: 5,5 kW

Układ hydrauliczny: Sterowanie ręczne przyciskowe z funkcją podtrzymania ciśnienia oraz automatycznego doładowania ciśnienia

Wymiary (D x S x W): 13 300 x 1 300 x 2 300 mm

Waga netto: ok. 15 t

1. Zawór przelewowy i elektrozawór zwrotny: Zhenping Hydraulics

2. Pompa olejowa i silnik: Shanghai Volkswagen + Guangdong Juntai

3. Cylinder olejowy i przewód olejowy wysokociśnieniowy: Zhengtian, ręczna produkcja, stabilna jakość i wysoka trwałość

4. Uszczelnienie cylindra olejowego: Taiwan Dingji (wysokowydajne uszczelnienie)

Mali oglas

Częstochowa

Częstochowa

602 km

Obdelovalni center

CNC INFOTEC Machining centerModel: 3121

Klic

Stanje: zelo dobro (rabljeno), CNC INFOTEC machining center Model: 3121

3 axes

Ibjdpfx Aoun Rqyeh Aof

Year of manufacture: 2016

Machine working area dimensions (axes):

X: 2200 mm Y: 3100 mm

Head travel (Z-axis): 250 mm

Working speed (X, Y, Z): X: 60 m/min, Y: 60 m/min, Z: 12 m/min

Vacuum table

Price for a new machine: approx. €75,000

Mali oglas

Hermaringen

Hermaringen

448 km

Obdelovalni center

MAKAKPF 334R

Klic

Stanje: dober (rabljeno), Leto izdelave: 2000, MAKA KPF 334R

Year of manufacture: 2000

Compact design with integrated control cabinet in the machine base frame.

CNC control unit BWO 900C, 1 MB memory, with integrated PC.

Technical Data:

Working areas / travel dimensions:

With tool length 130 mm and diameter 60 mm

X-axis: 1,000 mm

Ibedpfx Ahoir Aq Tj Ajf

Y-axis: 1,000 mm

Z-axis: 300 mm (with fixture height 120 mm)

A-axis: 540°

B-axis: 200° (+/- 100°)

Rapid traverse speeds:

X/Y-axis: 45 m/min

Z-axis: 15 m/min

A/B-axis: 10,000 °/min

1 high-speed milling spindle HSD 6.8 kW,

continuously variable speed control from 2,000 – 24,000 rpm,

nominal power from 12,000 rpm.

With ceramic bearings, air-cooled.

Tool holder SK 30 with automatic tool changer.

1 moving drum-type tool magazine for 10 tools up to Ø 60 mm and – depending on tool diameter – 130 mm length from reference face.

Aluminum table plate 1,000 x 1,000 mm with grid bores

1 vacuum pump 54 m³/h, 1 x vacuum clamping circuit

Automatic central lubrication,

Control cabinet with air conditioner.

Occupational safety:

Sliding door for front loading, safety enclosure at the machine rear, with side access door, enclosure is open at the top.

Connections:

Voltage: 400 V (max. +/- 5%) Frequency: 50 Hz

The use of an RCD (Residual Current Device) in the machine supply line is not possible.

Operating temperature: 10 – 35° C

Pneumatics: 6 bar, approx. 18 m³/h

No tool holders or machining tools are included in the scope of delivery.

Used machine, sold without any warranty or guarantee.

Dražba

Dražba končana

Bayern

Bayern

493 km

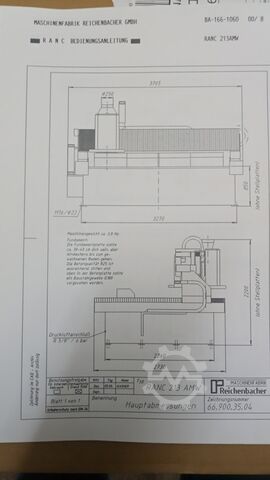

Obdelovalni center

Reichenbacher213-AMW

Stanje: pripravljen za uporabo (rabljen), Leto izdelave: 1993, obratovalne ure: 6.643 h, Funkcionalnost: popolnoma funkcionalen, številka stroja/vozila: BA-166-1060, potovalna razdalja osi X: 2.200 mm, pomik osi Y: 1.250 mm, pomik po osi Z: 250 mm, proizvajalec krmilnikov: Siemens, model krmilnika: 840 M, širina mize: 3.000 mm, dolžina mize: 1.490 mm, največja hitrost vrtenja: 18.000 obr/min, No reserve price – guaranteed sale to the highest bidder!

TECHNICAL DETAILS

X-axis travel: 2,200 mm

Y-axis travel: 1,250 mm (+250 mm tool change stroke)

Z-axis travel: 250 mm

B-axis: ±30°

Iodpfewxvv Eox Ah Aobf

Working area: 2,200 x 1,250 mm

Power/Speed: 7.5 kW at 12,000 to 18,000 rpm

Control system: Siemens Sinumerik 840 M

Table Dimensions

Table width (X direction): 3,000 mm

Table length (Y direction): 1,490 mm

Feed Rates

X-axis: 30 m/min linear

Y-axis: 30 m/min linear

Z-axis: 10 m/min linear

X/Y plane: 20 m/min linear, circular

X/Y plane rapid traverse: up to 42 m/min

Programming: manually or externally via interface

Program memory: 64 k = 59,000 characters

Main programs: 9,999 addressable

Subprograms: 999 addressable

Display: color display 14", 39 x 78 characters

Interpolation types: 3D linear, 2 ½ D circular

Tool compensation: fully automatic for radius and length

Program functions: zero point shift, adjustment control, start impulse memory, program lock, program mirroring

MACHINE DETAILS

Machine weight: approx. 3,900 kg

Dimensions: 3,705 x 2,730 x 2,200 mm

Connected load: 18 kW

Frequency converter: 1 x 33 kVA

Connection voltage: 380 V / 50 Hz or 415 V / 60 Hz

Rated current: 41 A

Main fuse: 3 x 50 A

Connection cross-section: 5 (4) x 16 mm² (up to 150 m cable length)

Compressed Air

Compressed air connection: 6 bar / R 3/8"

Extraction

Extraction connection: 1 x Ø250 + 1 x Ø140

Recommended air velocity: at least 30 m/s

Mali oglas

Eibelstadt

Eibelstadt

545 km

Stroj za rezkanje CNC

FlexiCAMStealth 1525

Klic

Leto izdelave: 2020, Stanje: kot nova (razstavni stroj), Machine Data

• Gantry system with a fixed table and moving portal for minimal footprint

• Base, bridge, and bridge columns made from steel, welded in one piece, stress-relieved and machined

• Main machine components constructed from ribbed welded assemblies, optimized for the best stiffness-to-weight ratio, vibration damping, and high acceleration

• Each machine design is validated and optimized using Finite Element Analysis (FEA) to ensure maximum quality, performance, and safety

• Easily accessible machine table for straightforward loading and unloading by forklift or overhead crane

• Ground precision guides with high preload and additional cover band for optimum chip removal on all axes

• Brushless digital A/C servo motors and controllers on all axes

• Dual-side, synchronized drive on the X-axis (gantry drive)

• Rack-and-pinion drive on X and Y axes

• Precision ballscrew drives with dual bearing units on Z-axis

• Precision planetary gearboxes with low backlash

• Enclosed drag chains to protect cables from chips and dust

• High-quality shielded drag chain cables provide high reliability against malfunctions and failures

• X-axis working range 2,550 mm

• Y-axis working range 1,550 mm

• Z clearance 200 mm

• Z travel 280 mm

• Travel speed max. 80 m/min

• Network connection via Ethernet

• Remote maintenance via Internet

• Dimensions approx. 2,960 x 2,460 x 1,930 mm (L x W x H, without safety equipment)

• Total weight approx. 3,200 kg

CNC Control

• FlexiCAM ACS Control System Pro

• High-performance industrial CNC control "Made in Germany"

• DIN-ISO 66025 G-code compatible

• Industrial PC with 17" touchscreen monitor as HMI

• User-friendly machine control panel

• Rotary switches for feed and spindle speed

• Manual unit for setup operation with handwheel, axis & resolution selection, emergency stop button

• Windows keyboard and mouse

• Front USB port

• Ethernet port (RJ45)

• Includes remote maintenance via Internet

• Control and operator panel integrated into the control cabinet

Drive Technology

• Digital Siemens drive concept

• Siemens Sinamics V70 servo controllers

• Siemens Simotics 1FL6 servo motors

• Siemens MOTION-CONNECT cables and connectors

Spindle with Automatic Tool Changer

• Power consumption 8 kW (S1) / 10 kW (S6)

• Speed range 2,000 – 24,000 rpm, continuously programmable

• Ceramic bearings

• Cooling via integrated electric fan

• ISO 30 tool taper

• Max. 26 mm shank or tool diameter with ISO30 / ER40 tool holders

• Temperature monitoring

• Tool taper presence check in spindle

• Compressed air monitoring

• Compressed air supply required on customer side

Extraction Device for Automatic Tool Change

• Hose connection 120 mm diameter

• Pneumatic up/down for tool change

• Extraction device required for CE-compliant system operation

Tool Magazine

• Linear tool changer

• Prepared for 10 tool positions

6-Zone T-slot Hybrid Table / High-Pressure Vacuum Table

• Combination of mechanical clamping with the added benefit that a part can also be held with vacuum only

Isdpfx Ahshwd Eaj Aebf

• Zones can be manually controlled via ball valves

• Grid for use with foam rubber gasketing

Znak zaupanja

Prodajalci, certificirani pri Machineseeker

Mali oglas

Timișoara

Timișoara

483 km

Stroj za izdelavo čepov

SAOMML 250

Klic

Stanje: skoraj kot novo (rabljeno), Leto izdelave: 2009, CNC Saom MODEL ML 250

Ibjdot I U T Sepfx Ah Asf

Mali oglas

Częstochowa

Częstochowa

602 km

Obdelovalni center

CNC INFOTEC BearbeitungszentrumModell: 2515

Klic

Stanje: zelo dobro (rabljeno), CNC INFOTEC machining center Model: 2515

5 axes

Year of manufacture: 2018

Working area dimensions (X-Y axis): X 2100 mm, Y 3100 mm

Z-axis travel: 1250 mm

Machine traverse speed X, Y, Z: X: 80 m/min, Y: 80 m/min, Z: 12 m/min

Ibodeun Rqgopfx Ah Asf

Vacuum table

BECKER pump

HITECO spindle with HSK 63F tool holder interface

Mali oglas

Hermaringen

Hermaringen

448 km

Obdelovalni center

MAKAKPF 334 RT

Klic

Stanje: rabljeno, Leto izdelave: 1999, Used Machine MAKA KPF 334 RT

5-Axis CNC Machining Center

Year of Manufacture: 1999

High-performance CNC milling center for 5-axis machining, ideal for processing deep-drawn parts. Compact design with control cabinet integrated into the machine base. Equipped with automatic central lubrication and a control cabinet with air conditioning unit.

Design / Version:

Gantry-type machining center with 2 aluminum tables

Axis Information:

Axis: Size / Travel Distance / Speed

X-axis: 2,750 mm / 40 m/min

Y-/V-axis: 2,400 mm / 40 m/min

Z-axis: 700 mm / 15 m/min

Rotary axis: 540° / 10,000°/min

Swivel axis: 200° / 10,000°/min

Machine Connection:

Voltage: 400V

Voltage deviation: max. +/- 5%

Operating temperature: 10 - 35°C

Compressed air pressure: 6 bar

Working areas / Workpiece cube size:

X-axis: 2 x 1,000 mm (coupled 2,150 mm)

Y-axis: 1,000 mm

Z-axis: 400 mm

Specified values are based on a fixture height of 170 mm / tool length 60 mm.

1 Equipment

Iedpfxev S Ut Do Ah Aobf

1.1 Table Design

2 aluminum surface tables with threaded bushings for clamping, each 1,000 x 1,000 mm in size.

Tables can be coupled for processing large components.

Both table plates additionally receive threaded bushings and locating bushings (or dowel pins) for accepting the customer’s milling fixture as specified.

1.2 Vacuum supply

Machine is equipped with a vacuum system.

1 vacuum pump

1.3 Clamping system

1 vacuum clamping circuit with vacuum distribution unit, pressure gauge, and pressure switch. Quick-connect couplings mounted to the machine table.

1.4 Milling unit:

1 pc. DFM 83/90 milling spindle, ER16 / M22 x 1.5

2.5 kW / 27,000 rpm

Universal unit for 5-axis milling with 90° head, tool holder ER16 / M22 x 1.5

1,000 to 27,000 rpm (infinitely variable speed), air-cooled.

A-axis 540° (rotary axis +/- 270°)

B-axis 200° (swivel axis +/- 100°)

1.5 Axis drives

Ball screw in X-, Y-, and Z-axes; A/B-axes with hollow-shaft drives.

1.6 Operator safety

One automatic sliding door per table.

Including safety cabin.

1.7 Control system

1 pc. BWO 900 machine control, with 1 pc. BWO 900C operating panel mounted on a mobile operator's console.

1.8 Power supply

Machine is designed for the following mains voltage:

Voltage: 400 V (max. +/- 5%)

Installed power: approx. 9 kW

Frequency: 50 Hz

The use of an RCD (Residual Current Device) in the machine power supply is not permitted.

1.9 Country specification

Technical machine documentation in German.

Consisting of:

- Operating manual for the machine

- Operating manual for the control system

- Wiring diagrams for electrical and pneumatic systems

- Control language in German.

Mali oglas

Eibelstadt

Eibelstadt

545 km

CNC STRUŽNICA

FlexiCAMStealth 1530

Klic

Leto izdelave: 2018, Stanje: kot nova (razstavni stroj), Machine Data

• Gantry-type machine with fixed table and moving portal for minimal footprint

• Machine base, bridge, and uprights constructed from one-piece welded, stress-relieved, and machined steel

• Main machine assemblies made from ribbed welded structures, optimized for best stiffness-to-weight ratio, vibration dampening, and high acceleration

• Every machine design is validated and optimized using Finite Element Analysis (FEA) to ensure maximum quality, performance, and safety

Isdpfx Aeflpmdjh Aobf

• Easily accessible machine table allows convenient loading/unloading with forklift or overhead crane

• Ground precision linear guides with high preload and additional cover strip for optimal chip removal on all axes

• Brushless digital AC servo motors and drives on all axes

• Double-sided synchronized drive on X-axis (gantry drive)

• Rack and pinion drive on X and Y axes

• Precision ball screws with double-end bearing units on Z axis

• Precision planetary gears with minimal backlash

• Enclosed cable drag chains protect cable harnesses from chips and dust

• High-quality shielded drag chain cables ensure high interference protection and operational reliability

• X travel: 3,050 mm

• Y travel: 1,550 mm

• Z clearance: 200 mm

• Z travel: 280 mm

• Max. traverse speed: 80 m/min

• Network connection via Ethernet

• Remote maintenance via Internet

• Dimensions approx. 3,460 x 2,460 x 1,930 mm (L x W x H, without safety devices)

• Total weight approx. 3,500 kg

CNC Control

• Siemens Sinumerik 808D Advanced

• LCD color display

• Mechanical keys, IP65 protection

• 62-key operator panel

• Technology-specific keyboard layout

• Operator panel with 39 keys and 30 LEDs

• LED tool number display

• Rotary switches for feed and spindle speed

• Handheld operator box with handwheel, axis & resolution selection, emergency stop

• Front USB port (IP65)

• Ethernet port (RJ45)

• Comprehensive training and offline programming tools available

Drive Technology

• Digital Siemens drive concept

• Siemens Sinamics V70 servo controllers

• Siemens Simotics 1FL6 servo motors

• Siemens MOTION-CONNECT cables and connectors

Spindle with Automatic Tool Changer

• Power consumption 8 kW (S1) / 10 kW (S6)

• Speed 2,000 – 24,000 rpm

• Ceramic bearings

• Cooling by integrated electric fan

• ISO 30 tool taper

• Max. 26 mm shaft or tool diameter with ISO30 / ER40 tool holders

• Temperature monitoring

• Safety query for tool taper in spindle

• Compressed air monitoring

Extraction Device for Automatic Tool Change

• Hose connection 120 mm diameter

• Manual height adjustment

• Pneumatically up/down for tool change

Tool Magazine

• Linear tool changer, mounted outside work area at rear of machine

• Max. 12 tool positions

• ISO30 / ER32 tool holders included (4x)

6-Zone High-Pressure Vacuum Table

• Hard paper tabletop (25 mm thick)

• Zones manually controlled via ball valves

High-Pressure Vacuum Pump per Customer Specification

Precision Tool Length Sensor

CE Package

Delivery, Commissioning & Training as agreed

Olajšamo vam iskanje

Nove ponudbe prejmete takoj in brezplačno po e-pošti.

Iskalno nalogo lahko kadar koli preprosto končate.

Rabljeni obdelovalni centri z ravno ali mrežasto mizo (327)

Zdaj preiščite celoten Machineseeker z več kot 200.000 rabljenimi stroji.Brskajte po najbolj priljubljenih poimenovanjih strojev:

- Bar Obdelovalni Center

- Cnc Obdelovalni Center

- Cnc Rezkalni Stroj In Obdelovalni Center

- Ex Tiskovno Središče

- Lesa Obdelovalni Center

- Mlin Za Mletje

- Moehle Mlin Za Meso

- Nakladalec S Rovokopači

- Obdelovalni Center

Izvedite več zdaj

+44 20 806 810 84

+44 20 806 810 84

Objavite oglas zdaj

*na oglas/mesec