Cevi Machine nakup rabljenega (65.689)

Noord-Brabant

Noord-Brabant Globokovrtalni stroj

IXION1TLF

Schleswig-Holstein

Schleswig-Holstein Laser rezalni stroj

TRUMPFTruLaser Tube 5000 (T01)

Schleswig-Holstein

Schleswig-Holstein Laser rezalni stroj

TRUMPFTruLaser 5030 7kW (L16)

+44 20 806 810 84

Tirol

Tirol CNC stružnica švicarskega tipa

STAR MicronisECAS 32 T

Baden-Württemberg

Baden-Württemberg Navpični obdelovalni center

MazakVTC 300C II

Odkrijte več rabljenih strojev

Bayern

Bayern Horizontalni strojni center

MAKINOA 500z

Bayern

Bayern Večvretenični stroj

EMAGVSC 200 TWIN

Bayern

Bayern Horizontalni strojni center

DMGNHX 5000

Schwanberg

Schwanberg Rezkalni stroj za utore

SCMformula as 16

Petrovče

Petrovče Laser rezalni stroj

TRUMPFTruLaser 3030 - Ersatzteile

Slovenija

Slovenija Stroj za izdelavo betonskih blokov

HESS15002.1 SVA

Rečica ob Savinji

Rečica ob Savinji Industrijski pralni stroj za težke obremenitve

ZippelD-93073

Rečica ob Savinji

Rečica ob Savinji Vertikalni obdelovalni center

DOOSANDNM6500

Rečica ob Savinji

Rečica ob Savinji Vertikalni obdelovalni center

DOOSANDNM4500

Aflenz Land

Aflenz Land Univerzalni obdelovalni center

DMG MORIDMU 65 monoBlock RS20

Slovenija

Slovenija Stroj za oblikovanje pločevine

METALKO BUČAR d.o.oMETALKO LUX 025

Aflenz Land

Aflenz Land Univerzalni obdelovalni center

DMG MORIDMU 60 eVo

Škofja vas

Škofja vas Obdelovalni Center

HOMAGBAZ 723

Aflenz Land

Aflenz Land Navpični obdelovalni center

HermleC800-U

Aflenz Land

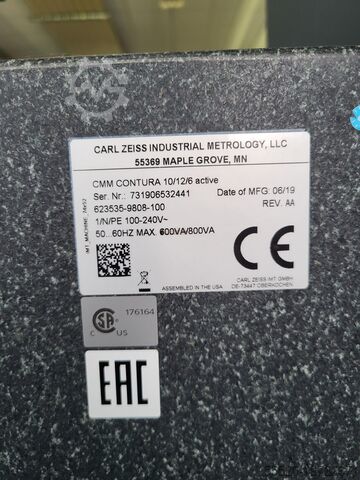

Aflenz Land ZEISS-ova koordinatna merilna naprava

ZeissCMM CONTURA 10126 active

Kuchl

Kuchl Drugi stroji za brušenje lesa

JetJSG 31A

Kuchl

Kuchl Drugi stroji za brušenje lesa

JETDDS 237

Slovenske Konjice

Slovenske Konjice Stroj za brizganje

FANUCRoboshot S100iB 125ton FULL ELECTRIC

Žalec

Žalec Rotational molding machine

PolivinilSRM 4500

Ravne na Koroškem

Ravne na Koroškem Stroj za brizganje

BATTENFELDPLUS 350/75

Rabljeni Cevi Machine (65.689)

Zdaj preiščite celoten Machineseeker z več kot 200.000 rabljenimi stroji.Brskajte po najbolj priljubljenih poimenovanjih strojev:

+44 20 806 810 84