Vzdrževanje Golf Course nakup rabljenega (2.437)

Norveška

Norveška Gradbeni stroj

WessexRMX560 lawn mower

Zheng Zhou Shi

Zheng Zhou Shi Oprema za drobljenje

Henan Mingyuan HSI Impact crusherStone crushing plant for sand aggregate

Бургас

Бургас Industrijski robot

KUKAKR 200 (4x)

+44 20 806 810 84

Бургас

Бургас Industrijski robot

KUKAKR 360 KRC4

Hauzenberg

Hauzenberg Laser rezalni stroj

LEDI LaserLG-6080

Odkrijte več rabljenih strojev

Hauzenberg

Hauzenberg Laser rezalni stroj

LD-LaserLG-1313 3kW eco line

Hauzenberg

Hauzenberg Laser rezalni stroj

Ledi LaserLG-1530 3kW Eco Line

Concordia Sagittaria

Concordia Sagittaria Giljotinske škarje 2060 x 3 mm

Vimercati200/3

Falkenberg

Falkenberg Kompaktni bager

H&RH&R B33

Kuchl

Kuchl Stroj za struženje lesa / stružnica

HagerHDG 250

Vomp

Vomp Sekalnik lesa

MaweraRZM 200 wenig Betriebsstunden

Mindelheim

Mindelheim Pasovni brusilnik

BULA & FILSM182.1

Bicske

Bicske Odprta polprikolica s ponjavo

Schmitz CargobullCurtainsider Mega

Bicske

Bicske Hladilna polprikolica

Schmitz CargobullReefer Multitemp

Bicske

Bicske Hladilna polprikolica

Schmitz CargobullReefer Multitemp

Eichendorf

Eichendorf Stroj za rezanje s plamenom

ZinserZINSER Brennschneidanlage – CNC 500

Udine

Udine 1998 Brusilni-pometalni stroj znamke CAMAM model C/1N/1S

CamamC/1N/1S

Neukirchen beim Heiligen Blut

Neukirchen beim Heiligen Blut Hladna krožna žaga

MEPTiger 370 CNC-LR

Neukirchen beim Heiligen Blut

Neukirchen beim Heiligen Blut Dvostebrni popolnoma avtomatski tračni žaga

MEPSHARK 230-1 NC HS

Budapest

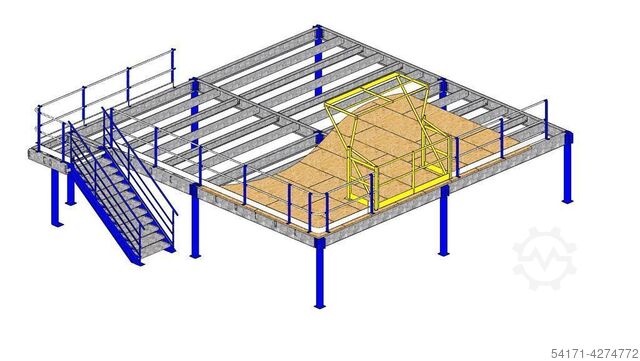

Budapest Treppe, Geländerschleuse, Klapptür

Budapest

Budapest Platforma za odlaganje različnih velikosti

Budapest

Budapest Težka polica

Hilo

Bicske

Bicske Hladilna polprikolica

Schmitz CargobullReefer Multitemp

Bruckmühl

Bruckmühl Gosenična delovna ploščad

Platform BasketSpider27.14

Hauzenberg

Hauzenberg Laserski stroj za rezanje

Ledi LaserLG-1530 6kW Premium Line

Rabljeni Vzdrževanje Golf Course (2.437)

Zdaj preiščite celoten Machineseeker z več kot 200.000 rabljenimi stroji.Brskajte po najbolj priljubljenih poimenovanjih strojev:

+44 20 806 810 84