Nesting nakup rabljenega (336)

Razvrsti rezultate

- Najnižja cena Najvišja cena

- Najnovejši oglasi Najstarejši oglasi

- Najkrajša razdalja Največja razdalja

- Najnovejše leto izdelave Najstarejše leto izdelave

- Zadnja posodobitev Najstarejša posodobitev

- Proizvajalci od A do Ž Proizvajalec od Z do A

- Pomembnost

- Najnižja cena

- Cena

- Najvišja cena

- Cena

- Najnovejši oglasi

- Datum objave

- Najstarejši oglasi

- Datum objave

- Najkrajša razdalja

- Razdalja

- Največja razdalja

- Razdalja

- Najnovejše leto izdelave

- Leto izdelave

- Najstarejše leto izdelave

- Leto izdelave

- Zadnja posodobitev

- Nazadnje posodobljeno

- Najstarejša posodobitev

- Nazadnje posodobljeno

- Proizvajalci od A do Ž

- Proizvajalec

- Proizvajalec od Z do A

- Proizvajalec

- Oznaka od A do Ž

- Oznaka

- Oznaka od Z do A

- Oznaka

- Model od A do Ž

- Model

- Model od Z do A

- Model

- Najnižja referenca

- referenca

- Najvišja referenca

- referenca

- Najkrajši obratovalni čas

- Obratovalni čas

- Najdaljši čas obratovanja

- Obratovalni čas

- Pomembnost

- Pomembnost

Mali oglas

Italija

Italija

514 km

Obdelovalni center z gnezdilno mizo

WEEKEBHP 200

Klic

Stanje: rabljeno, številka stroja/vozila: 005289, Delovno območje os X: 7400 mm

Delovno območje os Y: 1550 mm

Delovna površina: Nesting miza

Moč glavnega vretena: 11 kW

Število kontroliranih osi: 4 osi

Nedpfx Abjwcyacsbjkt

Število vrtalnih vreten: 10

Število mest za orodja: 14

Mali oglas

Leipzig

Leipzig

609 km

CNC obdelovalni center

WINTERROUTERMAX HP 2513 ATC HP

Klic

Stanje: novo, Dimensions (L/W/H): 2200 x 3300 x 2100 mm

Weight: 3000 kg

Total power requirement: 18 kW

CNC Machining Center ROUTERMAX HP 2513 ATC HP

Njdsv A Hbzjpfx Abbekt

- Showroom / demonstration machine

- As new, only a few operating hours

- Vibration-free marble-granite frame ensures maximum precision

- Working area X-axis: 2500 mm

- Working area Y-axis: 1300 mm

- Working area Z-axis: 200 mm

- Milling spindle, air-cooled HSD / Italy, 9.5 kW, ISO 30

- Spindle speed infinitely variable up to 24,000 rpm

- 8-position tool changer, side-mounted

- Drive system (X & Y axes): ball screw

- Drive system (Z axis): ball screw

- Drive motors: YASKAWA AC servo motors

- Linear guides in X, Y, and Z axes: 30 mm

- Max. traverse speed: 40 m/min

- Max. working speed: 20 m/min

- Working accuracy: 0.05 mm

- Vacuum grid table with 4 sections and T-slots

- Dry-running vacuum pump, power: 5.5 kW

- Tool length sensor

- CAD/CAM software: VECTRIC CUT 2D PRO (nesting included)

- Control system: WEIHONG with CNC handwheel included

- Interface: Ethernet/USB/CompactFlash card

- Electrical connection: 3-phase, 400 V, 50 Hz

- Operating ambient temperature: 0–45°C

- Width: 3300 mm

- Length: 2200 mm

- Weight: 3000 kg

Mali oglas

Leipzig

Leipzig

609 km

CNC obdelovalni center

WINTERROUTERMAX 1530 ECO

Klic

Stanje: novo, Leto izdelave: 2025, Dimensions (L/W/H): 3800 x 2300 x 2100 mm

Weight: 1900 kg

Total power requirement: 13 kW

CNC machining center ROUTERMAX 1530 ECO

- Working area X-axis: 1500 mm

- Working area Y-axis: 3000 mm

- Working area Z-axis: 300 mm

- Milling spindle: water-cooled, 4.5 kW each, ER 25, with CHILLER CW 3000 cooling unit

- Spindle speed: steplessly adjustable up to 22,000 rpm

- Drive system (X & Y axes): rack and pinion

- Drive system (Z axis): ball screw

- Drive motors: stepper motors

- Max. traverse speed: 22 m/min

- Max. working speed: 15 m/min

- Working accuracy: 0.05 mm

- Vacuum matrix table with 4 zones and T-slots

- Vacuum pump: 5.5 kW, dry-running, air-cooled

- Tool length sensor

- Controller: DSP type NK 105 (MACH3 OPTION)

- Interface: USB

- CAD/CAM software: Vectric Cut2D PRO (including nesting)

Nsdpfsv A Ha Rjx Abbokt

- Electrical connection: 3-phase, 400 V, 50 Hz

- Operating ambient temperature: 0-45°C

- Width: 2300 mm

- Length: 3800 mm

- Weight: 1900 kg

Izvedite več zdaj

+44 20 806 810 84

+44 20 806 810 84

Objavite oglas zdaj

*na oglas/mesec

Mali oglas

Leipzig

Leipzig

609 km

CNC obdelovalni center

WINTERROUTERMAX 1325 FLEX 4SP

Klic

Stanje: novo, Leto izdelave: 2025, Dimensions (L/W/H): 3300 x 2100 x 2100 mm

Weight: 1,500 kg

Total power requirement: 20 kW

CNC Machining Center ROUTERMAX 1325 FLEX 4SP

- X-axis working area: 1,300 mm

- Y-axis working area: 2,500 mm

- Z-axis working area: 180 mm

- 4 x 3.2 kW water-cooled milling spindles, ER 25, with CHILLER CW 3000 cooling unit

- The 4 spindles can be controlled independently or operate simultaneously

- 4 x chip extraction hoods

- Spindle speed: 6,000 – 24,000 rpm

- Travel system (X & Y axes): rack-and-pinion drive

- Travel system (Z axis): ball screw drive

- Travel motors: stepper motors

- Max. traversing speed: 20 m/min

- Max. working speed: 12 m/min

- Working accuracy: 0.05 mm

- Vacuum grid table with 4 zones and T-slots

- 5.5 kW dry-running, air-cooled vacuum pump

Nkjdpfx Ajv A Haqsbbot

- Tool length sensor

- Controller: DSP type NK 105

- Interface: USB

- CAD/CAM software: Vectric Cut2D PRO (NESTING included)

- Electrical connection: 3-phase 400 V, 50 Hz

- Operating temperature range: 0–45°C

- Width: 2,100 mm

- Length: 3,300 mm

- Weight: 1,500 kg

Mali oglas

Leipzig

Leipzig

609 km

CNC obdelovalni center

WINTERROUTERMAX ATC 2160 ECO

Klic

Stanje: novo, Leto izdelave: 2025, Dimensions (Length/Width/Height): 7000 x 2900 x 2100 mm

Weight: 4,900 kg

Total Power Requirement: 36 kW

CNC Machining Center ROUTERMAX ATC 2160 ECO

- Working Area X-Axis: 2,100 mm

- Working Area Y-Axis: 6,000 mm

- Working Area Z-Axis: 300 mm

- Milling Spindle: air-cooled, 9.0 kW, ISO 30

- Spindle Speed: stepless up to 24,000 rpm

- Tool Changer: 12-position, side-mounted

- Drive System (X & Y Axis): rack and pinion

- Drive System (Z Axis): ball screw

- Travel Motors: AC servo motors, Leadshine 850 W

- SHIMPO gearbox drive

- Max. Traversing Speed: 45 m/min

- Max. Working Speed: 20 m/min

- Working Precision: 0.05 mm

- Vacuum grid table with 12 zones and T-slots

Nkjdpfjv A E U Tsx Abbet

- 2 vacuum pumps, 11.0 kW each, air-cooled

- Workpiece positioning: pneumatically retractable stops, 4 each in X and Y

- Tool length sensor

- CAD/CAM software: VECTRIC CUT 2D PRO (nesting included)

- Control: DSP NK105 G3

- Interface: USB

- Electrical connection: 3-phase 400 V, 50 Hz

- Operating ambient temperature: 0–45°C

- Dimensions: Width 2,900 mm

- Dimensions: Length 7,000 mm

- Weight: 4,900 kg

Mali oglas

Leipzig

Leipzig

609 km

CNC obdelovalni center

WINTERROUTERMAX ATC 2150 ECO

Klic

Stanje: novo, Leto izdelave: 2025, Dimensions (LxWxH): 6000 x 2900 x 2100 mm

Weight: 4500 kg

Total Power Requirement: 36 kW

CNC Machining Center ROUTERMAX ATC 2150 ECO

- Working area X-axis: 2100 mm

- Working area Y-axis: 5000 mm

- Working area Z-axis: 300 mm

- Milling spindle, air-cooled, 9.0 kW, ISO 30

- Spindle speed, stepless: 24,000 rpm

- Tool changer: 12-position, side-mounted

- Drive system (X & Y axis): rack and pinion

- Drive system (Z axis): ball screw

- Traverse motors: AC servo motors Leadshine 850 W

- SHIMPO gear drive

- Max. traverse speed: 45 m/min

- Max. working speed: 20 m/min

- Working accuracy: 0.05 mm

- Vacuum matrix table with 10 sections and T-slots

- 2 vacuum pumps, 11.0 kW each, air-cooled

- Workpiece positioning: Pneumatically lowering stops, 4 each on X and Y

Nkedpfx Aov A E Uyobbot

- Tool length sensor

- CAD/CAM software: VECTRIC CUT 2D PRO (NESTING included)

- Control system: DSP NK105 G3

- Interface: USB

- Power supply: 3-phase, 400 V, 50 Hz

- Operating ambient temperature: 0–45°C

- Width: 2900 mm

- Length: 6000 mm

- Weight: 4500 kg

Mali oglas

Leipzig

Leipzig

609 km

CNC obdelovalni center

WINTERROUTERMAX ATC 2140 ECO

Klic

Stanje: novo, Leto izdelave: 2025, Dimensions (L/W/H): 5000 x 2900 x 2100 mm

Weight: 2,900 kg

Total power requirement: 24 kW

CNC Machining Center ROUTERMAX ATC 2140 ECO

- Working area X-axis: 2,100 mm

- Working area Y-axis: 4,000 mm

- Working area Z-axis: 300 mm

Nsdev A E Utepfx Abbskt

- Milling spindle, air-cooled, 9.5 kW, ISO 30

- Spindle speed infinitely variable up to 24,000 rpm

- Tool changer, 12-position, lateral

- Travel system (X & Y axis): Rack and pinion drive

- Travel system (Z axis): Ball screw

- Travel motors: AC servo motors, Leadshine 850 W

- Max. traverse speed: 45 m/min

- Max. working speed: 20 m/min

- Working accuracy: 0.05 mm

- Vacuum grid table with 8 zones and T-slots

- 2 x vacuum pumps, 5.5 kW each, air-cooled

- Workpiece positioning: pneumatically retractable stops, 2 each on X and Y

- Tool length sensor

- CAD/CAM software: VECTRIC CUT 2D PRO (NESTING included)

- Control system: DSP NK105 G3

- Interface: USB

- Electrical connection: 3-phase, 400 V, 50 Hz

- Operating ambient temperature: 0-45°C

- Dimensions, width: 2,900 mm

- Dimensions, length: 5,000 mm

- Weight: 2,900 kg

Mali oglas

Leipzig

Leipzig

609 km

CNC obdelovalni center

WINTERROUTERMAX ATC 1530 ECO

Klic

Stanje: novo, Leto izdelave: 2025, Dimensions (L/W/H): 4000 x 2300 x 2100 mm

Weight: 2300 kg

Total power requirement: 21 kW

CNC machining center ROUTERMAX ATC 1530 ECO

- Working area X-axis: 1500 mm

- Working area Y-axis: 3000 mm

- Working area Z-axis: 300 mm

- Milling spindle, air-cooled, 9.5 kW, ISO 30

- Spindle speed, infinitely variable: 24,000 rpm

- Tool changer, 12-position, side-mounted

- Drive system (X & Y axes): Rack and pinion drive

- Drive system (Z axis): Ball screw

- Drive motors: AC servo motors, Leadshine 850 W

- Max. traverse speed: 45 m/min

Nkodpfx Abov A E Tvsbet

- Max. working speed: 20 m/min

- Working accuracy: 0.05 mm

- Vacuum grid table with 6 zones and T-slots

- Vacuum pump 7.5 kW, air-cooled

- Workpiece positioning: Pneumatically retractable stops, 2 each on X and Y axes

- Tool length sensor

- CAD/CAM software: VECTRIC CUT 2D PRO (nesting included)

- Control: DSP NK105 G3

- Interface: USB

- Electrical connection: 3-phase, 400 V, 50 Hz

- Operating ambient temperature: 0-45°C

- Width: 2300 mm

- Length: 4000 mm

- Weight: 2300 kg

Mali oglas

Leipzig

Leipzig

609 km

CNC obdelovalni center

WINTERROUTERMAX ATC 1530 DELUXE

Klic

Stanje: novo, Leto izdelave: 2025, Dimensions (Length/Width/Height): 3800x2300x2100 mm

Weight: 2000 kg

Total power requirement: 19 kW

CNC Machining Center ROUTERMAX ATC 1530 DELUXE

- Working area X-axis: 1500 mm

- Working area Y-axis: 3000 mm

- Working area Z-axis: 300 mm

- Milling spindle, air-cooled, HITECO / Italy, 9.5 kW, HSK 63F

- Infinitely variable spindle speed: 24,000 rpm

- 8-position tool changer, side-mounted

- Drive system (X & Y axis): rack and pinion

- Drive system (Z axis): ball screw

- Drive motors: AC servo motors Delta / YASKAWA

- SHIMPO gearbox drive

- Max. traverse speed: 40 m/min

- Max. working speed: 20 m/min

Nksdpfx Abev A E Tpjbst

- Working accuracy: 0.05 mm

- Vacuum matrix table with 4 zones and T-slots

- BECKER vacuum pump, oil-free, air-cooled, capacity 129 m³/h

- Pneumatic workpiece positioning stops, retractable: 2 in X, 2 in Y

- Tool length sensor

- CAD/CAM software VECTRIC 2D PRO (NESTING included)

- Safety light curtain according to EN 848-3 (optional, depending on local installation conditions)

- OSAI control system / Italy

- Interfaces: Ethernet/USB/CompactFlash Card

- Electrical connection: 3-phase, 400 V, 50 Hz

- Operating ambient temperature: 0–45°C

- Dimensions width: 2300 mm

- Dimensions length: 3800 mm

- Weight: 2000 kg

Mali oglas

Leipzig

Leipzig

609 km

CNC obdelovalni center

WINTERROUTERMAX ATC 1325 ECO

Klic

Stanje: novo, Leto izdelave: 2025, Dimensions (L/W/H): 3300 x 2250 x 2100 mm

Weight: 2000 kg

Total power requirement: 19 kW

CNC Machining Center ROUTERMAX ATC 1325 ECO

- X-axis working area: 1300 mm

- Y-axis working area: 2500 mm

- Z-axis working area: 300 mm

- Air-cooled milling spindle, 9.5 kW, ISO 30

- Infinitely variable spindle speed: 24,000 rpm

- 8-position tool changer, lateral

- Travel system (X & Y axis): rack and pinion drive

- Travel system (Z axis): ball screw

- Travel motors: Leadshine 850 W AC servo motors

- Max. traverse speed: 45 m/min

- Max. working speed: 20 m/min

- Working accuracy: 0.05 mm

- Vacuum grid table with 6 zones and T-slots

Nkjdpfx Abov A E Tcebot

- Vacuum pump: 5.5 kW, air-cooled

- Workpiece positioning: pneumatically retractable stops, 2 on X and 2 on Y axis

- Tool length sensor

- CAD/CAM software: VECTRIC CUT 2D PRO (includes nesting)

- Controller: DSP NK105 G3

- Interface: USB

- Electrical connection: 3-phase, 400 V, 50 Hz

- Operating ambient temperature: 0–45°C

- Width: 2250 mm

- Length: 3300 mm

- Weight: 2000 kg

Mali oglas

Leipzig

Leipzig

609 km

CNC obdelovalni center

WINTERROUTERMAX 1313 ATC DELUXE

Klic

Stanje: novo, Leto izdelave: 2025, Dimensions (L/W/H): 0x0x0 mm

Weight: 1000 kg

Total power requirement: 15 kW

CNC Machining Center ROUTERMAX 1313 ATC DELUXE

- Working area X-axis: 1300 mm

- Working area Y-axis: 1300 mm

- Working area Z-axis: 200 mm

- Working accuracy: ±0.04/300 mm

- Vacuum grid table with 4 sections and T-slots including vacuum pump

- Max. traverse speed: 10,000 mm/min

- Max. working speed: 6,000 mm/min

- Milling spindle motor: 9.0 kW / ISO 30, air-cooled

Nksdpfxov A E Sxe Abbet

- Tool changer: 8-position, side-mounted

- Collet tool holder diameters: 6, 8, 10, 12, 14, 16, 20 mm

- Spindle speed max.: 24,000 rpm

- Drive motors: AC servo motors Leadshine 850 W

- Voltage: 400 V/50Hz

- Guideways in X, Y direction: Linear guide + rack and pinion

- Guideways in X, Z direction: Linear guide + ball screw

- Command language: G-code

- Interface: USB

- DSP controller NK 105 G3 (Option: Mach3 controller, PC and monitor)

- CAD/CAM software: Vectric CUT2D PRO (NESTING included)

- Workpiece positioning: 2 pneumatically retractable stops in X, 2 in Y

- Tool length sensor

- Safety light barrier as per EN 848-3 (Optional, depending on local installation requirements)

- Ambient temperature: 0-45°C

- Relative humidity: 30-75 %

- Weight: 1000 kg

Mali oglas

Ditzingen

Ditzingen

535 km

TISKALNA ZAVORA

TRUMPFTruBend 1060

Klic

Stanje: novo, Leto izdelave: 2025, Offer "Comfort Model": *

Equipped with a 4-axis backgauge, BendGuard, CNC-controlled crowning system, standard tool set, and hydraulic upper tool clamping to ensure quick and easy tool changes.

*The images shown are for illustrative purposes and may not correspond to the standard scope of the offer. For detailed offer specifications and further information, please feel free to contact us.

Nkjdpfxeiwxfio Abbst

About the machine:

Are you looking to enter TRUMPF bending technology while covering a wide range of applications? Then the TruBend 1000 is the ideal machine for you. The focus here is on the essentials: reliability, simple operation, high precision, and of course, the highest TRUMPF safety standards. Thanks to its robust design, high-quality components, and user-friendly programming system, the TruBend Series 1000 provides an ideal foundation for your entry into the world of TRUMPF bending. It is perfectly suited for box bending components in small and medium batch sizes.

Operate directly and intuitively

The TRUMPF control enables fast and easy numerical and graphical programming.

Bend precisely

With the 4-axis backgauge, you can position and bend even complex parts with precision.

TRUMPF quality

Our fast remote service support takes care of your needs, worldwide.

For further technical details, please refer to the data sheet or visit our website. If you have any questions, feel free to contact us.

About TRUMPF:

In our 100-year company history, we have helped shape many thousands of sheet metal productions in Germany alone. We pass on this experience to our customers every day. With innovative machines and functions, the industry's most comprehensive service concept, and experts in software, automation, and smart factory solutions, you always receive a customized offer tailored exactly to your requirements.

P.S.: We are also happy to assist you with financing. With the financing, leasing, or pay-per-use models from TRUMPF Financial Services, we are here to support you with both financial and business challenges.

Mali oglas

Nemčija

Nemčija

650 km

Stroj za lasersko rezanje z vlakni

ADIGELASERTUBE LT722D

Klic

Leto izdelave: 2021, obratovalne ure: 66.828 h, Stanje: pripravljen za uporabo (rabljen), Glavni pogon

Laserska moč: 2,5 kW

Dodatna oprema

Avtomatski podajalnik cevastih snopov za vhodne dolžine med 3.200 in 6.500 mm

Možno nalaganje z mostno dvigalo

Nosilnost nakladalca: 4.000 kg

Posebna dvižna oprema za kvadratne, pravokotne in ploščato-ovalne cevi

Ločevanje cevi z merilno postajo za dolžino

Oprema za podajalnik snopov dolžine 6.500 mm za cevi z občutljivo površino

Vključen programski paket Artube za optimizacijo razreza

ADIGE LASERTUBE LT722D je bil izdelan leta 2021. Namenjen je laserski obdelavi cevi ter omogoča obdelavo materialov kot so konstrukcijsko jeklo in nerjavno jeklo. Podpira različne oblike cevi, vključno z okroglimi, kvadratnimi in pravokotnimi, dimenzij do 140 mm. Glavne značilnosti vključujejo rezalno glavo PRECITEC AK-HP, avtomatski podajalnik cevastih snopov in robusten razkladalni sistem. Idealno za visokokakovostne laserske rezalne operacije. Za več informacij o stroju nas kontaktirajte.

Nkedpfjx D Nniex Abbjt

Področja uporabe

Rezanje

Mali oglas

Przełazy

Przełazy

678 km

Skladiščni vozički z možnostjo trojnega zlaganja v višino

Cordesmc200/250/270

Klic

Stanje: skoraj kot novo (rabljeno), We offer used warehouse trolleys designed for use in production, logistics, and storage facilities.

We operate on a model of steady, repeatable deliveries, targeting our offer primarily at business customers.

Offer:

• Warehouse / transport trolleys (various types and dimensions)

• Used trolleys, inspected and prepared for further operation

Nkjdpfxsx Nrvpe Abbst

• Continuous availability – regular product batches

• Possibility to assemble larger quantities

Intended for:

• Manufacturing plants

• Logistics centers

• Warehouses and wholesale facilities

• Manufacturers (including the furniture industry)

Why cooperate with us:

• Focus on long-term partnerships, not one-off sales

• Repeatable assortment and transparent conditions

• Extensive experience in serving B2B clients

• Possibility of regular deliveries and batch reservations

📦 Photos show currently available trolleys – our entire stock.

💰 Price determined individually – depending on volume and cooperation model.

📞 If you are interested in a reliable supplier of warehouse trolleys – please contact us.

3-fold stacking

Wheels: 100 mm polyamide, 4 swivel, 1 directional lock.

When empty, the trolleys can be collapsed and nested.

The Corletta can be used for in-plant transport and storage of nearly all types of goods. Thanks to the ability to stack up to three units, full use of warehouse height can be achieved.

We provide comprehensive trolley servicing.

This allows us to offer a 1-year warranty on used trolleys!

Delivery available across Europe!

Your specialist in Corlett sales and service

KAM-KUB Logistic & Trolleys Europe

Mali oglas

Almelo

Almelo

922 km

Obdelovalni center

DMA MACHINERY-ROUTERSEXPRESS1326-ATC

Klic

Stanje: novo, Leto izdelave: 2026, Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 2.600 mm, pomik osi Y: 1.300 mm, pomik po osi Z: 200 mm, hitro pomikanje X-os: 40 m/min, hitri pomik os Y: 40 m/min, hitri pomik na osi Z: 15 m/min, višina obdelovanca (maks.): 350 mm, skupna dolžina: 3.500 mm, skupna širina: 2.100 mm, vrtljajska hitrost (min.): 1.000 obr/min, največja hitrost vrtenja: 24.000 obr/min, skupna masa: 2.460 kg, vhodna napetost: 400 V, Oprema: dokumentacija / priročnik, transportni trak za ostružke, vrtilna hitrost brezstopenjsko nastavljiva, CNC Nesting Machine

EXPRESS-ROUTER CNC router is the new custom machining center for those who demand precision and reliability.

Designed and assembled in the Netherlands according to the strictest European standards.

This machine is engineered for small and medium-sized enterprises.

Nedpjx R D Rnjfx Abbekt

Featuring a robust welded steel frame, servo drive system, automatic tool changer, and intelligent software integration, it is the ideal solution for everything from cabinet making to complex 3D relief machining.

Why DMA MACHINERY

- Price & Quality

- Minimal floor space required

- Complies with the latest European Machinery Regulation (EU)2023/1230

- CNC Gantry Router

- Capable of processing: wood, plastic, aluminum, acrylic, foam, composites, etc.

- Unlimited possibilities

- No license fees

- CadCam software Pegasuds (see videos)

- 1 year online helpdesk support

CNC Machines: Honestly priced, for craftsmen who can do it themselves.

Pay for steel, not for service. Our CNCs are for the resourceful, independent entrepreneur.

Focus on functionality: Your machine, your control, our lowest price.

Choose self-assembly and save tens of thousands of euros on your new CNC machine.

The power of CNC without the overhead costs. For professionals with technical expertise.

Mali oglas

Almelo

Almelo

922 km

Obdelovalni center

DMA Machinery CNC-ROUTERSExpress-1326 ATC ( COMPACT )

Klic

Stanje: novo, Leto izdelave: 2026, Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 2.600 mm, pomik osi Y: 1.300 mm, pomik po osi Z: 200 mm, hitro pomikanje X-os: 60 m/min, hitri pomik os Y: 60 m/min, hitri pomik na osi Z: 20 m/min, proizvajalec krmilnikov: syntec, dolžina obdelovanca (maks.): 6.000 mm, širina obdelovanca (maks.): 2.100 mm, višina obdelovanca (maks.): 350 mm, skupna višina: 2.200 mm, skupna dolžina: 4.200 mm, skupna širina: 2.100 mm, obremenitev mize: 1.500 kg, vrtljajska hitrost (min.): 1.000 obr/min, največja hitrost vrtenja: 24.000 obr/min, skupna masa: 2.800 kg, nosilec vretena: MK 3, število mest v zalogovniku orodij: 10, vhodna napetost: 400 V, vrsta vhodnega toka: trifazni, Oprema: dokumentacija / priročnik, vrtilna hitrost brezstopenjsko nastavljiva, Cost savings for the end customer: €80,000 instead of €40,000

DMA supplies high-quality CNC machines at unbeatable prices, as costly service contracts and on-site installations are not required. Perfect for professionals who want to retain full control.

Included in the purchase price:

- "SYNTEC" CNC controller

- CNC nesting/milling CAD/CAM

Nksdpfx Aex Rz Auobbet

- PEGASUS Professional CAD/CAM including online training/helpdesk

- Starter kit with cutting and drilling tools for CNC sheet metal processing

• Spare parts supply: In the event of a defect within 12 months, spare parts will be shipped free of charge after diagnosis (photo/video). • Labor costs not included: You can replace the part yourself or hire an external service provider.

• Low-maintenance designs.

• Digital setup: via app or TeamViewer, direct online service. This eliminates the need for technician visits, saving time and money.

• Online service: 24/7 support.

Digital support as an alternative

• Video tutorials: Clips for calibration or part replacement.

• Exploded diagrams: Components immediately identifiable.

Functionality in focus: Your machine, your management, our best price.

Usable working area: 3200 x 1600 mm (standard sizes available).

Z-axis: 200 mm.

Automatic tool changer with 9-kW milling spindle.

Up to 26 spindle positions.

Row drilling unit optional. Slot milling unit optional.

CadCam nesting software.

Pressure rollers (for uneven material) optional.

Becker VTLF2.250 vacuum pump.

All axes servo-driven.

Heavy-Duty CNC Milling Machine

Type: "NESTING"

Working area: 1300 x 2600 mm (standard sizes available)

Z-axis: 200 mm

ATC 9 kW milling spindle

Drilling unit optional

Slot milling unit optional

CadCam nesting software

Pressure rollers (for uneven material) optional

Becker VTLF2.250 vacuum pump

All axes servo-driven

Mali oglas

Elsenfeld

Elsenfeld

599 km

Stroj za rezanje z vodnim curkom

Dardi International / FB-2030 NeuFB-2030 ESA / IGEMS/KEYENCE/Allfi

Klic

Stanje: novo, Leto izdelave: 2026, New installation from one of the world's largest manufacturers, Dardi International / Flying Bridge design, 3x2 m cutting area, 2-D, linear guides with ball screws on all three axes, Yaskawa motors with controllers.

Delivery time approx. 6–8 weeks, directly in our showroom in Elsenfeld with the following configuration:

Many machines of the same type can be inspected in Benelux, Switzerland, Germany, etc. in advance. Contact us for details.

-- Other sizes available on request --

Nkedpfsx Ig Sisx Abbjt

Machine:

- 2x3 m cutting area with stainless steel tank and wave-shaped, individually replaceable steel supports

- ESA PC control WIN 11

- IGEMS 2-D CAD/CAM programming system including automatic nesting to minimize material waste

- 1 cutting head, 2-D version

- Handwheel

- High-pressure supply via rotary union

- Automatic central lubrication system

- High-pressure supply with stab profile and shut-off valve

- Allfi® abrasive feeding system 1.3 to, fully automatic

- Allfi® abrasive dosing system 2.0, steplessly adjustable without pneumatics

- KEYENCE safety light curtains for CE compliance

- IGEMS and operator training as well as on-site installation available at additional cost

Price ex works Elsenfeld.

We are the European distributor for Dardi International with 26 years of experience in high-pressure waterjet systems.

Available at extra charge:

- High-pressure pump BFT Ecotron 40.37+

- Aqualon High Pressure Pump AQRO S50c 37 kW / 3.8 l/min

Optional: Manual tilting head available at extra charge, see photos.

Mali oglas

Kruibeke

Kruibeke

962 km

Obdelovalni center z zmogljivostjo

Igolden02P-WVQ

Klic

Stanje: zelo dobro (rabljeno), Leto izdelave: 2023, Funkcionalnost: popolnoma funkcionalen, 4-osni hranilni CNC stroj za izdelavo omar - sestavljen iz 4 delov - del 1: avtomatsko dvigalo plošč - del 2: avtomatski etiketirni stroj - del 3: 4-osni CNC - del 4: avtomatska izhodna miza - vseh 4 deli delujejo skupaj - vključno z odsesovalno napravo - vključno z vakuumsko črpalko za CNC mizo - kompatibilna rezkalna glava ISO30 ER32 - vključno s 3D programom za načrtovanje omar (Haixun programska oprema) Haixun quick design + Haixun quick production vključena - rezervni deli in etikete vključeni v tej ponudbi - dimenzije električne omare 80x60x190 cm - dimenzije odsesovalne naprave: 140x80x140 cm - dimenzije etiketirnega stroja: 4000x2700x1800 mm

Njdpfxov Dupve Abbskt

Mali oglas

Nemčija

Nemčija

394 km

CNC obdelovalni center

Holz-HerPro-Master 7123 M 500

Klic

Stanje: rabljeno, Leto izdelave: 2007, Rabljeni stroj

Letnik: 2007

Oprema in tehnični podatki:

Nesting naprava z rastrsko mizo

Obdelovalne mere:

- X: 5000 mm

- Y: 1240 mm

- Z: 135 mm

Pomiki osi:

- X: 5665 mm

- Y: 1650 mm

- Z: 325 mm

z rezkalno enoto 7933:

- Motor 11 kW (S6)

- HSK 63

- vodno hlajenje

z osjo C

z diskastim izmenjevalcem orodij za 18 mest

z vakuumsko črpalko 250 m³

z ročnim upravljalnikom

s centralnim mazanjem

z minimalnim mazalnim sistemom

Dobavljivost: takoj

Lokacija: Röllbach

Njdpfxswka Ipo Abbskt

Dražba

Dražba končana

Piemonte

Piemonte

591 km

Obdelovalni center

WEEKEVANTAGE 24 L

Stanje: pripravljen za uporabo (rabljen), Leto izdelave: 2010, Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 3.700 mm, pomik osi Y: 1.550 mm, hitrost pomika os X: 96 m/min, hitrost podajanja osi Y: 96 m/min, največja hitrost vrtenja: 24.000 obr/min, DÉTAILS TECHNIQUES

Course axe X : 3 700 mm

Course axe Y : 1 550 mm

Course axe X (levée) : 4 538 mm

Course axe Y (levée) : 1 952 mm

Nkjdoxw Up Sspfx Abbet

Passage maximal de la pièce : 100 mm

Vitesse de déplacement axe X : 96 m/min

Vitesse de déplacement axe Y : 96 m/min

Vitesse de déplacement axe Z : 25 m/min

Nombre d’axes commandés : 3 axes

Nombre de broches de perçage : 7

Nombre de positions d’outils : 8

Table de nesting

Longueur : 1 550 mm

Largeur : 3 700 mm

Matériau : Bakélite

Nombre de pompes : 4

Capacité individuelle : 108 m³/h

Unité de perçage

Unité : supérieure

Broches pour perçages verticaux : 7

Unité de fraisage

Unité : supérieure

Nombre d’axes commandés : 3

Changeur d’outils automatique : oui

Puissance du moteur : 9 kW

Vitesse max. : 24 000 tr/min

DÉTAILS MACHINE

Puissance totale installée : 26 kW

ÉQUIPEMENT

Pompe à vide

Système de contrôle PC85

Logiciel WoodWOP

Marquage CE

Rideaux immatériels de sécurité

Remarque : Les outils ne sont pas compris dans l’offre.

Dražba

Dražba končana

Piemonte

Piemonte

591 km

Obdelovalni center

REICHENBACHERARTIS X

Stanje: pripravljen za uporabo (rabljen), Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 2.500 mm, pomik osi Y: 1.300 mm, največja hitrost vretena: 18.000 obr/min, število osi: 5, TEHNIČNI PODATKI

Pomik osi X: 2.500 mm

Pomik osi Y: 1.300 mm

Število mest za orodja: 16

Vrtalna enota

Enota: zgoraj

Nsdpsxw Ukcefx Abbjkt

Vreten za vertikalno vrtanje: 7

Skupno število vertikalnih in horizontalnih vreten: 7

Rezkalna enota

Enota: zgoraj

Število kontroliranih osi: 5

avtomatska menjava orodij

Moč motorja: 7 kW

Največje število vrtljajev: 18.000 obr/min

PODROBNOSTI O STROJU

Nameščena skupna moč: 20 kW

OPREMA

Nesting

Zaščitna struktura enot

Varnostni senzorji

Na stroj pritrjene zaščitne ograje

Znak zaupanja

Prodajalci, certificirani pri Machineseeker

Mali oglas

Varaždin

Varaždin

105 km

Obdelovalni Center

SCMmorbidelli x400

Klic

Stanje: zelo dobro (rabljeno), Leto izdelave: 2023, Funkcionalnost: popolnoma funkcionalen, CNC stroj Morbidelli X 400 z ravno (gnezdenje) mizo

Njdpfoxqzm Dex Abbjkt

Mali oglas

Plzeň-město

Plzeň-město

418 km

Etiketirne postaje

BarbaricLabeling LPS

Klic

Leto izdelave: 2021, Stanje: zelo dobro (rabljeno), Funkcionalnost: popolnoma funkcionalen, Etiketirne postaje Barbaric Labeling LPS, letnik 2021, vsaka z tiskalnikom etiket Godex EZ235I. Fiksna miza, primerna za avtomatska skladišča ali CNC stroje za gnezdenje.

Nkjdpfx Aboxy Ad Aobot

Mali oglas

Nemčija

Nemčija

661 km

CNC obdelovalni center s skladiščem plošč

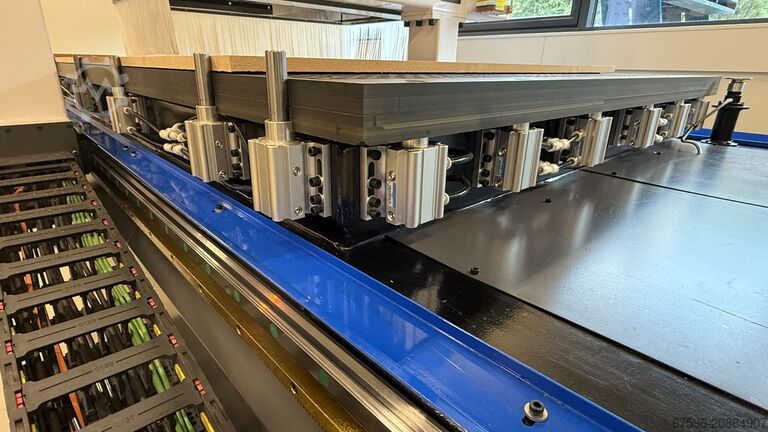

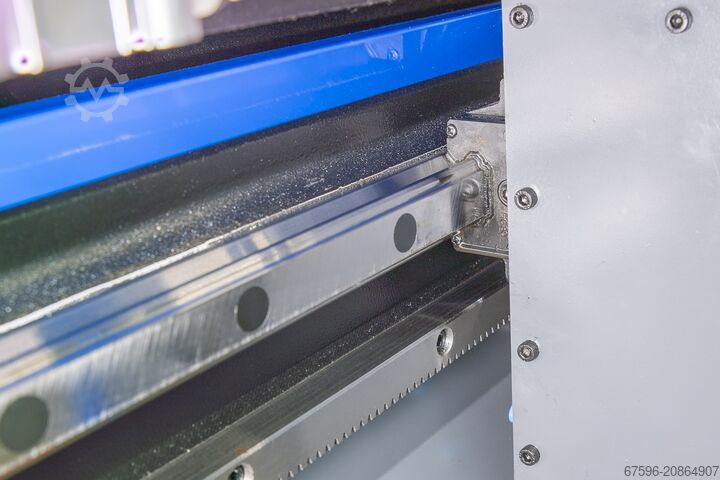

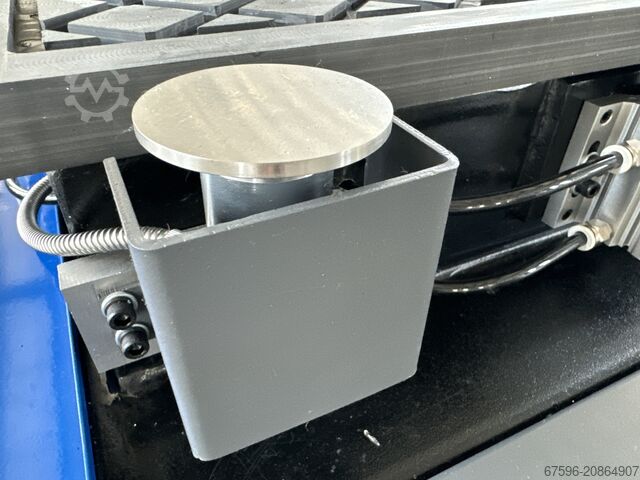

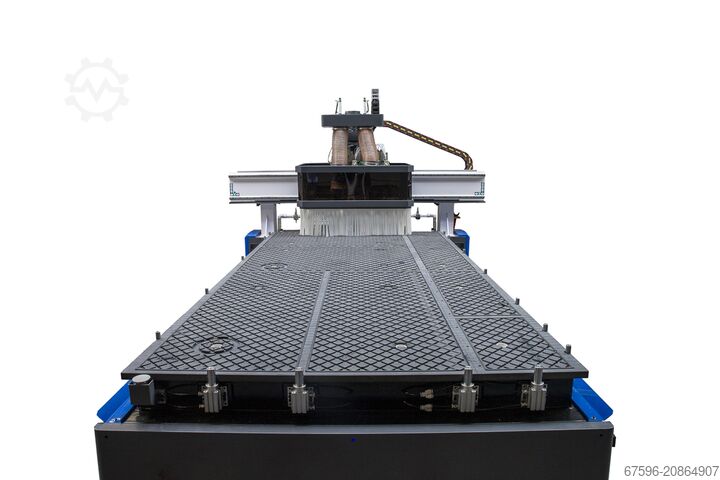

Holz-HerDynestic 7532 10.5 automatic mit Store-Master 511

Klic

Stanje: rabljeno, Leto izdelave: 2019, Used machine

Year of manufacture: 2019

Equipment and technical data:

- Designed for classic nesting machining with wear plate

- Machine frame in welded construction with ground and hardened prism guides for the gantry, spindle head, and consoles

- Gantry-type moving bridge

- Helical rack-and-pinion drive in X and Y axes; ball screw drive in Z axis for precise positioning

- Working dimensions:

- Max. clamping surface on nesting table:

X = 3100 mm, Y = 1560 mm

- Max. travel range:

X = 4695 mm, Y = 2100 mm, Z = 293 mm

- Max. clearance height on DYNESTIC table:

Z = 100 mm from table top (without wear plate)

- Maximum programmable speed:

Vector speed: 128 m/min

X = 80 m/min, Y = 100 m/min, Z = 25 m/min

- DYNESTIC table:

- Fixed, continuous machining table with grid division

- Continuous T-slots in X and Y directions

- Slot spacing 50 mm

Nksdpfswka Upsx Abbjt

- Includes 25 meters of sealing cord for securing the wear plate

- Vacuum zones: single-circuit vacuum system

- Drilling unit 7877:

- 19 spindles

- Drive power: 1.7 kW

- 13 vertical spindles:

- Individually selectable

- U-shaped arrangement

- 5+4 in X-direction, 4 in Y-direction

- 32 mm pitch

- Maximum drill diameter: 35 mm

- Total drill length: 70 mm from mounting end (depends on panel thickness)

- Spindle stroke: 70 mm

- Reversible rotation (CW/CCW)

- n(max): 1000–4400 rpm, stepless

- Mount: M10 thread, 11 mm fit

- Without tools, without holder

- 6 horizontal spindles:

- 2 double drilling spindles in X-direction

- 1 double drilling spindle in Y-direction

- Mount: M10 thread, 11 mm fit

- Max. drill length: 63 mm from mounting end

- Without tools, without holder

- Milling unit 7842:

- Power: 12.0 kW (S6 duty cycle)

- n(max) = 1000–24000 rpm, stepless

- Max. output at 12000–24000 rpm

- Air-cooled

- With HSK-F 63 tool holder

- With right-hand threaded nut (for right-hand tools)

- With collet chuck for HSK shank

- Hybrid ceramic bearings

- Max. tool weight: 6 kg (including holder)

- Tools: milling and grinding tools up to max. Ø 160 mm

- Safety enclosure as per CE standards

- Safety fence on sides and rear

- Vacuum pump: 500 m³/h, dry-running

- Operator safety with light barriers in front machine area

- Handheld remote control unit for machine operation with following functions:

- Start / Stop machining program

- Speed control for machining cycles

- Reset button

- Manual feed / rapid traverse for all axes

- EMERGENCY STOP

- CAMPUS V7 CAD/CAM software—1x machine license comprising:

- CAMPUS NC-HOPS:

- Graphical parametric system with WOP and CAD/CAM features for creating part variants with macro technology

- CAMPUS MT-Manager

- CAMPUS Workcenter

- CAMPUS DXF interface

- Automatic central lubrication

- Automatic lubrication at defined intervals

- Additional dust sealing by means of overpressure in each guide carriage

Mali oglas

Iași

Iași

969 km

Cnc stružnica

EMAGVL 2

Klic

Stanje: rabljeno, Leto izdelave: 2013, Funkcionalnost: omejena funkcionalnost, številka stroja/vozila: 105032, Caracteristici tehnice:

Arie de lucru

# Diametru maxim al plăcii de strângere: 160 mm

# Diametru maxim de strunjire: 160 mm

# Diametru maxim de prelucrare: 100 mm

# Lungime maximă piesă de prelucrat: 150 mm

# Cursă pe axa X: 700 mm / Avans rapid pe axa X: 60 m/min

# Cursă pe axa Z: 375 mm / Avans rapid pe axa Z: 30 m/min

# Automatizare închisa standard (număr de cuiburi de încărcare cu diametru piesă ,14/(80...200),18/(30...160), 30/(30...85))

Ax principal

# Arbore principal conform DIN 55026: Mărime A5

# Turație maximă: 6000 rpm

# Putere la ciclu de funcționare 100 / 40%: 18,1 / 13,9 kW

# Cuplu la ciclu de funcț. 100 / 40%: 77 / 59 Nm

Portscule cu scule antrenate

# Suport prindere pal cilindric conform DIN 69880: 12 - BMT65

# Număr poziții: 12

# Lungime maximă sculă (cu suport inclus): 190 mm

# Turație maximă: 6000 rpm

# Cuplu maxim la ciclu 10%: 27 Nm, la ciclu 100%: 14 Nm

Echipament electric

# Tensiune de alimentare: 400 - 480 V, 80 A

# Putere instalată: 27 kVA

Dimensiuni

# Dimensiuni totale: Lungime=4350 mm cu evacuator span, Lățime=1600 mm, Înălțime=2500 mm

# Greutate: 5500 kg

Caracteristici principale și capabilități:

# Construcție verticală: Evacuare optimă a spanului și încărcare/descărcare facilă.

# Control: GE Fanuc FS 32i B.

# Precizie ridicată: Precizie de poziționare pe axe X,Z ±0,001 mm; rigle liniare Haidenhain

# Arbore principal: Putere mare și plajă largă de turații.

# Control în proces: palpator de măsurare Marposs T25

# Încărcare/descărcare automată: Piese alimentate și preluate din utilaj prin automatizare integrată.

# Scule antrenate: Posibilitate de utilizare scule antrenate pentru găurire și frezare.

# Monitorizare durată de viață scule cu management tip "sister tool"

# Bandă transportoare span, unitate răcire, filtru dublu schimbabil, pompă înaltă presiune 15 bar

# Zonă de lucru complet închisă, iluminare spațiu de lucru

# Documentație: electronică disponibilă & carte incompletă

Nkodpfx Ajxxwztjbbet

Stare utilaj:

FUNCȚIONAL

# Panou de siguranță operator – spart

Olajšamo vam iskanje: "nesting"

Nove ponudbe prejmete takoj in brezplačno po e-pošti.

Iskalno nalogo lahko kadar koli preprosto končate.

Rabljeni Nesting (336)

Zdaj preiščite celoten Machineseeker z več kot 200.000 rabljenimi stroji.Brskajte po najbolj priljubljenih poimenovanjih strojev:

Izvedite več zdaj

+44 20 806 810 84

+44 20 806 810 84

Objavite oglas zdaj

*na oglas/mesec