Rabljena popolna polnilna linija za mirno vino - 8000 steklenic na uro (BPH)APE Impianti

Rabljena popolna polnilna linija za mirno vino - 8000 steklenic na uro (BPH)

APE Impianti

Stanje

Rabljeno

Lokacija

Italija

Prikaži slike

Prikaži karto

Podatki o stroju

Cena in lokacija

- Lokacija:

- , Italija

Klic

Podrobnosti ponudbe

- ID ponudbe:

- A21193520

- Št. reference:

- LC597

- Nazadnje posodobljeno:

- dne 24.02.2026

Opis

Technical specifications and performance data

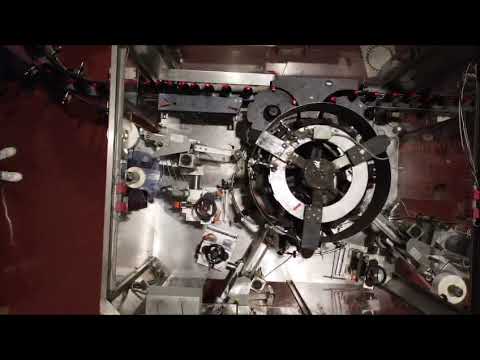

This used bottling line is designed for reliable beverage production and downstream industrial packaging, achieving up to 8,000 bottles per hour (bph). The configuration integrates an MBF filling monoblock (2002), consisting of rinser, filler, and capper, specifically engineered for straight flush cork closure technology. The line also includes a ROBINO & GALANDRINO POKER Z 6/8 (2002) capsule and shrink machine, followed by APE Impianti carton handling and KOSME labeling technology. This equipment offers robust performance for used plant settings and flexible format management, as typically required for glass and PET bottles.

Production speed: 8,000 bottles per hour

Filling monoblock: MBF (year 2002) – rinser, filler, capper

Closure type: straight flush cork

Capsuling/shrinking: ROBINO & GALANDRINO POKER Z 6/8 (year 2002)

Compatible formats: Typical carton pattern includes 12 x 0.75 L; additional formats manageable with changeover kits

Containers: Suitable for bottle handling; configuration supports glass (cylindrical containers)

Labeling modules: KOSME STAR 720 12T (cold glue) and KOSME EXTRA ADHESIVE 12T S3 E3 (self-adhesive)

Labeling capabilities: Front, back, and neckband (collarino) application

Packaging modules: APE FORMA 2000 (carton erector), APE INCA 2010 (carton packer), APE INSER 2001 (partition inserter)

Electrical (MBF monoblock): 380 V, 50 Hz; installed power 17 kW

Electrical (labelers): 400 V, 50 Hz; installed power 4 kW (STAR) or 8 kW (EXTRA ADHESIVE)

Pneumatics (MBF): 0.6 MPa (6 bar); air consumption 200 Nl/min

Weights: 9,000 kg (MBF monoblock), 2,650 kg (STAR 720 12T), 2,000 kg (EXTRA ADHESIVE 12T S3 E3)

Compliance: CE-marked components

Advanced automation and control systems

The line uses modular automation across filling, labeling, and carton stations to ensure stable throughput. The MBF monoblock and Robino & Galandrino POKER Z operate in synchronized mode, ensuring precise fill heights, hermetic straight cork sealing, and professional capsule handling. The KOSME labelers are configured for complex equipment requirements and allow synchronized application of front, back, and neckband labels. Operator-friendly controls on each module support fast commissioning and format changeovers. APE Impianti packaging modules offer synchronized motions and interlocked safety guards for downstream processes.

Integration capability in production lines

Nkedpfjyh E Huex Ag Tju

This bottling line is engineered to work inline with conveyors and buffer zones to achieve the 8,000 bph target. The MBF filling core

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

This used bottling line is designed for reliable beverage production and downstream industrial packaging, achieving up to 8,000 bottles per hour (bph). The configuration integrates an MBF filling monoblock (2002), consisting of rinser, filler, and capper, specifically engineered for straight flush cork closure technology. The line also includes a ROBINO & GALANDRINO POKER Z 6/8 (2002) capsule and shrink machine, followed by APE Impianti carton handling and KOSME labeling technology. This equipment offers robust performance for used plant settings and flexible format management, as typically required for glass and PET bottles.

Production speed: 8,000 bottles per hour

Filling monoblock: MBF (year 2002) – rinser, filler, capper

Closure type: straight flush cork

Capsuling/shrinking: ROBINO & GALANDRINO POKER Z 6/8 (year 2002)

Compatible formats: Typical carton pattern includes 12 x 0.75 L; additional formats manageable with changeover kits

Containers: Suitable for bottle handling; configuration supports glass (cylindrical containers)

Labeling modules: KOSME STAR 720 12T (cold glue) and KOSME EXTRA ADHESIVE 12T S3 E3 (self-adhesive)

Labeling capabilities: Front, back, and neckband (collarino) application

Packaging modules: APE FORMA 2000 (carton erector), APE INCA 2010 (carton packer), APE INSER 2001 (partition inserter)

Electrical (MBF monoblock): 380 V, 50 Hz; installed power 17 kW

Electrical (labelers): 400 V, 50 Hz; installed power 4 kW (STAR) or 8 kW (EXTRA ADHESIVE)

Pneumatics (MBF): 0.6 MPa (6 bar); air consumption 200 Nl/min

Weights: 9,000 kg (MBF monoblock), 2,650 kg (STAR 720 12T), 2,000 kg (EXTRA ADHESIVE 12T S3 E3)

Compliance: CE-marked components

Advanced automation and control systems

The line uses modular automation across filling, labeling, and carton stations to ensure stable throughput. The MBF monoblock and Robino & Galandrino POKER Z operate in synchronized mode, ensuring precise fill heights, hermetic straight cork sealing, and professional capsule handling. The KOSME labelers are configured for complex equipment requirements and allow synchronized application of front, back, and neckband labels. Operator-friendly controls on each module support fast commissioning and format changeovers. APE Impianti packaging modules offer synchronized motions and interlocked safety guards for downstream processes.

Integration capability in production lines

Nkedpfjyh E Huex Ag Tju

This bottling line is engineered to work inline with conveyors and buffer zones to achieve the 8,000 bph target. The MBF filling core

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Dokumenti

Ponudnik

Opomba: Brezplačno se registrirajte ali prijavite, za dostop do vseh informacij.

Registriran od: 2021

Pošlji zahtevo

Telefon & Faks

+39 344 0... oglasi

Ti oglasi bi vas prav tako lahko zanimali.

Mali oglas

Fumane (Verona)

Fumane (Verona)

326 km

Pakirnica za kovčke

APE ImpiantiInca 2001

APE ImpiantiInca 2001

Mali oglas

Italia

Italia

514 km

Stroj za proizvodnjo pijač

Bottling MBFBottling WINE Bottling Line 10.000 bph

Bottling MBFBottling WINE Bottling Line 10.000 bph

Mali oglas

Fumane (Verona)

Fumane (Verona)

326 km

Erektor ohišja

APE ImpiantiForm 1200 HM

APE ImpiantiForm 1200 HM

Mali oglas

Fumane (Verona)

Fumane (Verona)

326 km

Pakirnica za kovčke

APE ImpiantiINCA 2000

APE ImpiantiINCA 2000

Mali oglas

Fumane (Verona)

Fumane (Verona)

326 km

Polnjenje monoblokov

GAI2405

GAI2405

Mali oglas

Fumane (Verona)

Fumane (Verona)

326 km

Erektor ohišja

APE ImpiantiForm 2000 HM SX

APE ImpiantiForm 2000 HM SX

Mali oglas

Fumane (Verona)

Fumane (Verona)

326 km

Erektor ohišja

APE ImpiantiFORM1500 HMB

APE ImpiantiFORM1500 HMB

Mali oglas

Freinsheim

Freinsheim

629 km

Stroj za pijače

BertolasoType 63/40/6/6

BertolasoType 63/40/6/6

Mali oglas

Oirschot

Oirschot

924 km

Merilnik pretoka

Endress+HauserProline Promag H 300

Endress+HauserProline Promag H 300

Mali oglas

Fumane (Verona)

Fumane (Verona)

326 km

Polnjenje monoblokov

BertolasoOlimpia 12/12/1

BertolasoOlimpia 12/12/1

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake