Univerzalni obdelovalni centerReiden

RX10-5X

Univerzalni obdelovalni center

Reiden

RX10-5X

VB plus DDV

330.900 €

Stanje

Rabljeno

Lokacija

Gütersloh

Prikaži slike

Prikaži karto

Podatki o stroju

- Oznaka stroja:

- Univerzalni obdelovalni center

- Proizvajalec:

- Reiden

- Model:

- RX10-5X

- Stanje:

- zelo dobro (rabljeno)

Cena in lokacija

VB plus DDV

330.900 €

- Lokacija:

- Dietrichstr. 103, 33335 Gütersloh, Deutschland

Pokliči

Podrobnosti ponudbe

- ID oglasa:

- A20125415

- Posodobitev:

- nazadnje dne 28.02.2026

Opis

5-axis machining center

with swivel milling head, pallet station, tool calibration, thermal compensation, work area extraction, and much more.

Year of manufacture: 2016

Spindle hours approx. 1,500 h (after spindle replacement, beginning of 2025)

Control:

Heidenhain iTNC 530 HSCI

Heidenhain DCM collision monitoring

Heidenhain HR 410 handwheel

Swiveling console with 19" monitor

Teleservice via LAN/WLAN

Travel range:

Travel X 1,000 mm, Y 1,100 mm, Z 810 mm

NC rotary table D 1,000 x 800 mm, swing circle 1,350 mm

Milling head:

Automatic horizontal/vertical swivel head

fully-fledged stepless NC axis from -1° to +90°

Blow air through the spindle

External cooling via nozzle ring

Drive power 38 kW (100% duty cycle)

Speed 16,000 rpm

Torque 135 Nm at 40% duty cycle

Spindle taper HSK 63-A

Medium supply:

Internal coolant supply 50 bar - output 28 l/min

Paper belt filter with additional fine filter

Pressure regulation for individual tools during program run

Tool changer:

Rack magazine with 73 stations (expandable with additional racks)

Swiveling dialog control panel

Drawer for inserting/removing tools in/from the tool magazine

Cpsdexhg Dispfx Afnow

Tool measurement:

3D wireless touch probe m&h 20.00-Multi, software adjustment for HSK 63-A

Includes Kinematics-Opt, matched to iTNC control, and calibration sphere on magnetic stand

Pallet changer:

Dual pallet unit, pallet diameter 1,000 x 800 mm, hole pattern 100mm x 100mm, hardened drill bushings D 16mm

Rotary table unit incl. zero-point clamping system, loading station accessible for crane.

Pallet change unit protected by enclosure.

Special equipment:

Micro-Epsilon

for detection and dynamic compensation of thermally induced spindle growth

Chip conveyor

Scraper belt conveyor, longitudinal to machine bed

Chip discharge height 1,100 mm

Machine enclosure

Full-space protective cladding with large angled door for crane loading and a quick access door.

Easy removal of chips from the working area.

Extraction unit

Oil and emulsion mist extraction, mechanical air filter, suction power 1,800 m³/h

Rotating viewing window

Viewing window integrated into the work area door

Camera in the working area

Monitor and keyboard at the control panel. Allows observation of rear-side machining.

Machine data:

Space requirements (without service areas!) LxWxH approx. 4,791 mm x 4,100 mm x 4,791 mm (including extraction unit)

Machine weight approx. 19,700 kg

Total weight with complete equipment, plus max. workpiece load, fully loaded tool magazine, all operating materials: approx. 27,730 kg

Connected load 50 kVA, 400V, 50/60 Hz

This machining center, with an exceptionally good and practical configuration, is in excellent condition. It operates with the customary "Swiss precision." The machine does not have any backlog of maintenance or repairs—quite the opposite. With an almost new milling spindle, the REIDEN RX 10 5X is very well positioned for the long term.

Technical modifications and errors excepted.

Oglas je bil avtomatsko preveden. Možne so napake pri prevodu.

with swivel milling head, pallet station, tool calibration, thermal compensation, work area extraction, and much more.

Year of manufacture: 2016

Spindle hours approx. 1,500 h (after spindle replacement, beginning of 2025)

Control:

Heidenhain iTNC 530 HSCI

Heidenhain DCM collision monitoring

Heidenhain HR 410 handwheel

Swiveling console with 19" monitor

Teleservice via LAN/WLAN

Travel range:

Travel X 1,000 mm, Y 1,100 mm, Z 810 mm

NC rotary table D 1,000 x 800 mm, swing circle 1,350 mm

Milling head:

Automatic horizontal/vertical swivel head

fully-fledged stepless NC axis from -1° to +90°

Blow air through the spindle

External cooling via nozzle ring

Drive power 38 kW (100% duty cycle)

Speed 16,000 rpm

Torque 135 Nm at 40% duty cycle

Spindle taper HSK 63-A

Medium supply:

Internal coolant supply 50 bar - output 28 l/min

Paper belt filter with additional fine filter

Pressure regulation for individual tools during program run

Tool changer:

Rack magazine with 73 stations (expandable with additional racks)

Swiveling dialog control panel

Drawer for inserting/removing tools in/from the tool magazine

Cpsdexhg Dispfx Afnow

Tool measurement:

3D wireless touch probe m&h 20.00-Multi, software adjustment for HSK 63-A

Includes Kinematics-Opt, matched to iTNC control, and calibration sphere on magnetic stand

Pallet changer:

Dual pallet unit, pallet diameter 1,000 x 800 mm, hole pattern 100mm x 100mm, hardened drill bushings D 16mm

Rotary table unit incl. zero-point clamping system, loading station accessible for crane.

Pallet change unit protected by enclosure.

Special equipment:

Micro-Epsilon

for detection and dynamic compensation of thermally induced spindle growth

Chip conveyor

Scraper belt conveyor, longitudinal to machine bed

Chip discharge height 1,100 mm

Machine enclosure

Full-space protective cladding with large angled door for crane loading and a quick access door.

Easy removal of chips from the working area.

Extraction unit

Oil and emulsion mist extraction, mechanical air filter, suction power 1,800 m³/h

Rotating viewing window

Viewing window integrated into the work area door

Camera in the working area

Monitor and keyboard at the control panel. Allows observation of rear-side machining.

Machine data:

Space requirements (without service areas!) LxWxH approx. 4,791 mm x 4,100 mm x 4,791 mm (including extraction unit)

Machine weight approx. 19,700 kg

Total weight with complete equipment, plus max. workpiece load, fully loaded tool magazine, all operating materials: approx. 27,730 kg

Connected load 50 kVA, 400V, 50/60 Hz

This machining center, with an exceptionally good and practical configuration, is in excellent condition. It operates with the customary "Swiss precision." The machine does not have any backlog of maintenance or repairs—quite the opposite. With an almost new milling spindle, the REIDEN RX 10 5X is very well positioned for the long term.

Technical modifications and errors excepted.

Oglas je bil avtomatsko preveden. Možne so napake pri prevodu.

Ponudnik

Opomba: Brezplačno se registrirajte ali prijavite, za dostop do vseh informacij.

Pošlji povpraševanje

Telefon & Faks

+49 173 2... oglasi

Ti oglasi bi vas prav tako lahko zanimali.

Mali oglas

Warren

Warren

7.284 km

Stroj za brušenje ročične gredi

LandisLT2

LandisLT2

Mali oglas

Europa

Europa

932 km

CNC stružni in rezkalni center

WFLM120 MILLTURN x 3000

WFLM120 MILLTURN x 3000

Mali oglas

Grüsch

Grüsch

415 km

Obdelovalni center - univerzalni

DECKEL- MAHODMU100P duoBLOCK

DECKEL- MAHODMU100P duoBLOCK

Mali oglas

Gondelsheim

Gondelsheim

576 km

Žerjav nadstrešek Žerjav Notranji žerjav Žerjavska steza

Demag Portalkran KBK 250KGKBKI/II KBK1/2 8x4m 250Kg DC Kettenzug

Demag Portalkran KBK 250KGKBKI/II KBK1/2 8x4m 250Kg DC Kettenzug

Mali oglas

Mažeikiai

Mažeikiai

1.242 km

Obdelovalni Center

HERMLEC1200U

HERMLEC1200U

Mali oglas

Burscough

Burscough

1.519 km

Brusilnik za orodje

HAASMultigrind

HAASMultigrind

Mali oglas

Nemčija

Nemčija

650 km

Obdelovalni center

SW Schwäbische WerkzeugmaschinenBAW06-22

SW Schwäbische WerkzeugmaschinenBAW06-22

Mali oglas

West Yorkshire

West Yorkshire

1.466 km

Razdelilnik za testo

Mondial Forni Dough DividerSV Asda

Mondial Forni Dough DividerSV Asda

Mali oglas

Lemmer

Lemmer

1.004 km

Stroj za rezkanje portalov

MTorresMGP-51350 TT

MTorresMGP-51350 TT

Mali oglas

Korschenbroich

Korschenbroich

838 km

CNC stroj za notranje izvlečenje

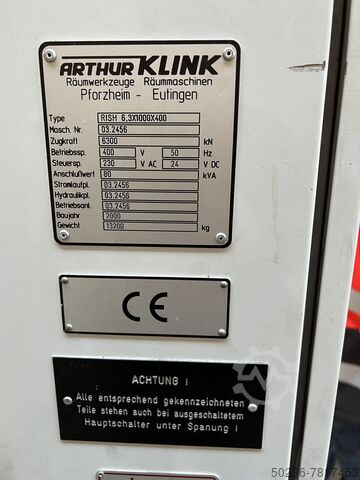

Arthur KlinkRISH 6.3X1000X400

Arthur KlinkRISH 6.3X1000X400

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake