Balenpres so predstlačno loputo LP 50 EH1Balirka s predpritisno loputo LP 50 EH1Presona AB

LP 50 EH1

Balenpres so predstlačno loputo LP 50 EH1Balirka s predpritisno loputo LP 50 EH1

Presona AB

LP 50 EH1

Leto izdelave

2005

Stanje

Rabljeno

Lokacija

Nizozemska

Prikaži slike

Prikaži karto

Podatki o stroju

- Proizvajalec:

- Presona AB

- Model:

- LP 50 EH1

- Leto izdelave:

- 2005

- Stanje:

- delavnici obnovljeno (rabljeno)

- Funkcionalnost:

- popolnoma funkcionalen

- Obratovalne ure:

- 30.408 h

Cena in lokacija

- Lokacija:

- , Nizozemska

Klic

Tehnične podrobnosti

- Stiskalna sila:

- 50 t

- Širina odprtine za polnjenje:

- 1.100 mm

- Dolžina polnilne odprtine:

- 1.250 mm

- Širina bale:

- 1.100 mm

- Višina bale:

- 720 mm

- Teža bale:

- 550 kg

- Skupna masa:

- 16.000 kg

- Kapaciteta rezervoarja za olje:

- 600 l

- Leto zadnje generalne obnove:

- 2024

Podrobnosti ponudbe

- ID ponudbe:

- A17766606

- Nazadnje posodobljeno:

- dne 20.06.2025

Opis

Technical Specifications of the Baler:

Manufacturer: Presona AB

Model: LP 50 EH1

Year of manufacture: 2005

Operating hours: 30,408 hours (as of April)

Number of bales produced: 198,059 (as of April)

Klsdpfx Afsu Thhro Nol

Main press force: 50 t

Specific press force: 63 N/cm²

Theoretical throughput: 530 m³/hour

Throughput under working conditions: 260 m³/hour

Feed hopper dimensions: 1,250 x 1,100 mm

Press chamber volume: 2.2 m³

Bale dimensions: 1,100 x 720 mm, length variable

Drive power: 22 kW

Tying: 5-fold vertical, fully automatic

Throughput rates at bulk density of:

30 kg/m³: 6 to 7 t/hour

50 kg/m³: 7 to 9 t/hour

100 kg/m³: 11 to 14 t/hour

Bale density (paper/newspaper): 400 to 550 kg/m³

Hydraulic oil tank capacity: 600 L

PLC control: Telemecanique TSX Micro

Control panel: Schneider Magelis

Effective transport dimensions (excluding baler): 8,125 x 2,300 x 3,000 mm (L x W x H)

Transport weight (baler): approx. 16 t

Condition of the baler:

The machine has been partially overhauled in our workshop and general maintenance work has been carried out. After completion of the overhaul, the baler was tested during operation and is available for sale at short notice.

The following overhaul work was performed:

General:

- Machine cleaned, derusted, primed, and partially repainted

- Wire entry marks in the press channel guideways welded and smoothed

Hydraulic unit:

- Hydraulic oil tank drained, tank cleaned, new oil filled

- Oil filter and air filter replaced

- Leaking oil sight glass on hydraulic oil tank replaced

- All hydraulic hoses replaced

Electrics:

- Menu language set to English in the program

- Two key switches on the control panel replaced

- Control cabinet replaced

- Signal lamp on the control cabinet replaced

- Limit switch for the flap replaced

- Electrics of the wirbulator renewed, connected, and tested

Press ram:

- All four guide rollers of the press ram removed and replaced

- Main hydraulic cylinder dismantled, disassembled, and partially overhauled; cylinder barrel honed, complete seal set replaced, leak test carried out

- All plastic wear pads on the press ram replaced

Pre-press flap:

- Both bearings on pre-press shaft replaced

- Both hydraulic cylinders dismantled, disassembled, and partially overhauled; both cylinder barrels honed, complete seal sets replaced, leak test carried out

- Scraper flap on pre-press replaced

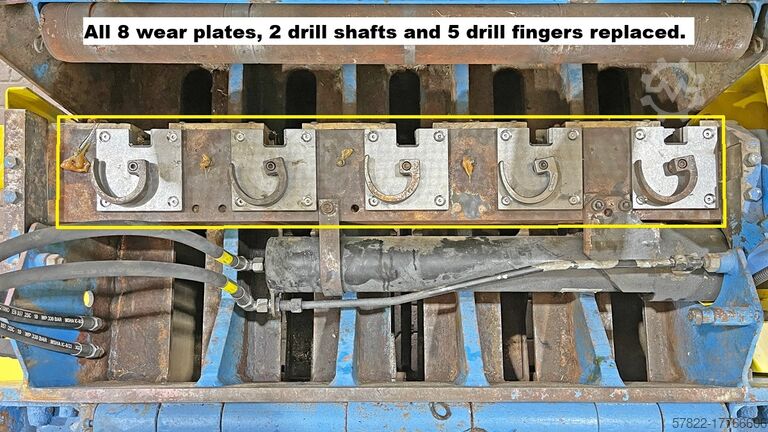

Tying unit:

- Two complete needles with wire guide rollers replaced

- Needles adjusted and set

- All wire guide rollers in the needle heads replaced

- Twister fingers replaced

- Two twister shafts replaced

- All 8 wear plates on the twist mechanism under the twister fingers replaced

Scope of delivery:

Only the baler is being sold.

Documentation (operating manual, CE declaration, electrical/hydraulic circuit diagram) is complete. Inspection by appointment. We assume no liability for the technical details or possible errors.

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Manufacturer: Presona AB

Model: LP 50 EH1

Year of manufacture: 2005

Operating hours: 30,408 hours (as of April)

Number of bales produced: 198,059 (as of April)

Klsdpfx Afsu Thhro Nol

Main press force: 50 t

Specific press force: 63 N/cm²

Theoretical throughput: 530 m³/hour

Throughput under working conditions: 260 m³/hour

Feed hopper dimensions: 1,250 x 1,100 mm

Press chamber volume: 2.2 m³

Bale dimensions: 1,100 x 720 mm, length variable

Drive power: 22 kW

Tying: 5-fold vertical, fully automatic

Throughput rates at bulk density of:

30 kg/m³: 6 to 7 t/hour

50 kg/m³: 7 to 9 t/hour

100 kg/m³: 11 to 14 t/hour

Bale density (paper/newspaper): 400 to 550 kg/m³

Hydraulic oil tank capacity: 600 L

PLC control: Telemecanique TSX Micro

Control panel: Schneider Magelis

Effective transport dimensions (excluding baler): 8,125 x 2,300 x 3,000 mm (L x W x H)

Transport weight (baler): approx. 16 t

Condition of the baler:

The machine has been partially overhauled in our workshop and general maintenance work has been carried out. After completion of the overhaul, the baler was tested during operation and is available for sale at short notice.

The following overhaul work was performed:

General:

- Machine cleaned, derusted, primed, and partially repainted

- Wire entry marks in the press channel guideways welded and smoothed

Hydraulic unit:

- Hydraulic oil tank drained, tank cleaned, new oil filled

- Oil filter and air filter replaced

- Leaking oil sight glass on hydraulic oil tank replaced

- All hydraulic hoses replaced

Electrics:

- Menu language set to English in the program

- Two key switches on the control panel replaced

- Control cabinet replaced

- Signal lamp on the control cabinet replaced

- Limit switch for the flap replaced

- Electrics of the wirbulator renewed, connected, and tested

Press ram:

- All four guide rollers of the press ram removed and replaced

- Main hydraulic cylinder dismantled, disassembled, and partially overhauled; cylinder barrel honed, complete seal set replaced, leak test carried out

- All plastic wear pads on the press ram replaced

Pre-press flap:

- Both bearings on pre-press shaft replaced

- Both hydraulic cylinders dismantled, disassembled, and partially overhauled; both cylinder barrels honed, complete seal sets replaced, leak test carried out

- Scraper flap on pre-press replaced

Tying unit:

- Two complete needles with wire guide rollers replaced

- Needles adjusted and set

- All wire guide rollers in the needle heads replaced

- Twister fingers replaced

- Two twister shafts replaced

- All 8 wear plates on the twist mechanism under the twister fingers replaced

Scope of delivery:

Only the baler is being sold.

Documentation (operating manual, CE declaration, electrical/hydraulic circuit diagram) is complete. Inspection by appointment. We assume no liability for the technical details or possible errors.

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Dokumenti

Ponudnik

Opomba: Brezplačno se registrirajte ali prijavite, za dostop do vseh informacij.

Registriran od: 2017

Pošlji zahtevo

Telefon & Faks

+31 597 2... oglasi

Ti oglasi bi vas prav tako lahko zanimali.

Mali oglas

Warburg

Warburg

733 km

Drobilnik z dvojno gredjo

Arjes / EggersmannImpaktor 250 EVO II

Arjes / EggersmannImpaktor 250 EVO II

Mali oglas

Spittal an der Drau

Spittal an der Drau

134 km

Drobilnik z eno gredjo

Lindner-Recyclingtech GmbHMERAK 2800

Lindner-Recyclingtech GmbHMERAK 2800

Mali oglas

Nemčija

Nemčija

614 km

Balirni stroj

DIXI40 SLK

DIXI40 SLK

Mali oglas

Nizozemska

Nizozemska

974 km

Balirka z 8-kratno križno vezavo

Presona ABLP 80 VHK 1

Presona ABLP 80 VHK 1

Mali oglas

Kaufungen

Kaufungen

695 km

Standardni vlačilec

MERCEDES-BENZActros 1845 SZM 4x2 Streamspace *Retarder

MERCEDES-BENZActros 1845 SZM 4x2 Streamspace *Retarder

Mali oglas

Blachownia

Blachownia

593 km

Stiskalnica za papir

American Baler COhydrauliczna

American Baler COhydrauliczna

Mali oglas

Wuppertal

Wuppertal

811 km

Reciklirni ekstruder - granulacijska naprava / kaskada

AGRIFONAM-145

AGRIFONAM-145

Mali oglas

Tata

Tata

301 km

Balirka za kanale Pal Pacomat V 50t

PAAL PACOMAT V50ton 500kg bale

PAAL PACOMAT V50ton 500kg bale

Mali oglas

Karlholmsbruk

Karlholmsbruk

1.609 km

Chipper

Söderhamn Eriksson670-56

Söderhamn Eriksson670-56

Mali oglas

Fohnsdorf

Fohnsdorf

119 km

Stiskalnica za odpadke

ATM Recyclingsystems GmbHPaketierpresse SP 100 AK-2

ATM Recyclingsystems GmbHPaketierpresse SP 100 AK-2

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake