Vertikalni Cnc Obdelovalni Center nakup rabljenega (22.412)

Razvrsti rezultate

- Najnižja cena Najvišja cena

- Najnovejši oglasi Najstarejši oglasi

- Najkrajša razdalja Največja razdalja

- Najnovejše leto izdelave Najstarejše leto izdelave

- Zadnja posodobitev Najstarejša posodobitev

- Proizvajalci od A do Ž Proizvajalec od Z do A

- Pomembnost

- Najnižja cena

- Cena

- Najvišja cena

- Cena

- Najnovejši oglasi

- Datum objave

- Najstarejši oglasi

- Datum objave

- Najkrajša razdalja

- Razdalja

- Največja razdalja

- Razdalja

- Najnovejše leto izdelave

- Leto izdelave

- Najstarejše leto izdelave

- Leto izdelave

- Zadnja posodobitev

- Nazadnje posodobljeno

- Najstarejša posodobitev

- Nazadnje posodobljeno

- Proizvajalci od A do Ž

- Proizvajalec

- Proizvajalec od Z do A

- Proizvajalec

- Oznaka od A do Ž

- Oznaka

- Oznaka od Z do A

- Oznaka

- Model od A do Ž

- Model

- Model od Z do A

- Model

- Najnižja referenca

- referenca

- Najvišja referenca

- referenca

- Najkrajši obratovalni čas

- Obratovalni čas

- Najdaljši čas obratovanja

- Obratovalni čas

- Pomembnost

- Pomembnost

Mali oglas

Wallerstein

Wallerstein

456 km

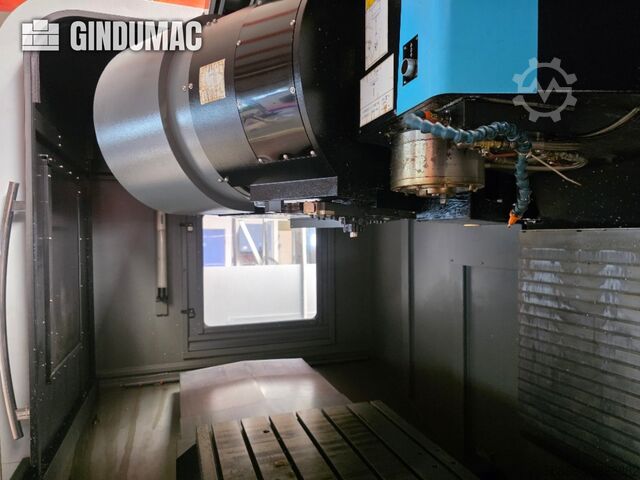

Vertikalni obdelovalni center

Deckel MahoDMC 635V

Klic

Stanje: zelo dobro (rabljeno), Leto izdelave: 2009, Funkcionalnost: popolnoma funkcionalen, Verticalne obrábacie centrum DECKEL MAHO DMC 635V

Rok výroby: 2009

CNC riadenie: Siemens 840D

Osi

Pojazd X-os mm: 635

Pojazd Y-os mm: 510

Pojazd Z-os mm: 460

Vzdialenosť vretena od povrchu stola mm: 720

Rýchlosť posuvu m/min: 20

Rýchloposuv m/min: 30

Zrýchlenie osi m/s2: 5

Pracovný stôl

Rozmery palety mm: 560×790

Max. hmotnosť obrobku kg: 600

Vreteno

Max. otáčky vretena ot./min: 14 000

Výkon pohonu vretena kW: 18,5/15 (40%ED/cont)

Krútiaci moment vretena Nm: 100/74

Systém nástrojov

Upínanie nástrojov: SK40

Počet nástrojov v zásobníku: 20

Elektronický ručný ovládač

Dopravník triesok

Vzduchové ofukovanie stredom vretena voliteľné cez M-funkciu

Priamy merací systém XYZ

Prevádzkové hodiny stroja:

Hodiny pod napätím: 14 500

Pracovný čas vretena: 3 600

Celkový príkon kVA: 35

Rozmery/Základný stroj/Hmotnosť

Dĺžka mm: 2 275

Šírka mm: 3 288

Lhjdsyay D Uopfx Abbeb

Výška mm: 2 670

Hmotnosť: 4,5 t

Vrátane upínačov a upínacích púzdier na nástroje

Mali oglas

Wallerstein

Wallerstein

456 km

Vertikalni obdelovalni center

Deckel MahoDMC 835V

Klic

Stanje: dober (rabljeno), Leto izdelave: 2007, Funkcionalnost: popolnoma funkcionalen, Proizvajalec: DECKEL MAHO DMC 835V

Leto izdelave: 2007

Krmiljenje: Siemens 840D / Shop Mill

Pomik X-os: 835 mm

Pomik Y-os: 510 mm

Pomik Z-os: 510 mm

Lodpfx Abeyaywbebshb

Hitrost vretena: 10.000 obr/min

Podajalna hitrost:

Programabilna do 15 m/min - hitri pomik 30 m/min

Pozicijska toleranca: 0,008 mm

Magazin orodij: 30 mest

Notranje hlajenje in transporter odrezkov

Teža cca 6,5 t

Mali oglas

Brno-město

Brno-město

358 km

Vertikalni obdelovalni center

BelottiEureka 4014

Klic

Stanje: rabljeno, Leto izdelave: 2001, obrati 18.000 - 24.000

Os X 4.000 mm

Os Y 1.400 mm

Lhedex Uqr Topfx Abbsb

Os Z 800 mm

Dimenzije stroja 6.400 mm x 2.600 mm x 3.800 mm

Izvedite več zdaj

+44 20 806 810 84

+44 20 806 810 84

Objavite oglas zdaj

*na oglas/mesec

Mali oglas

Cerklje na Gorenjskem

Cerklje na Gorenjskem

37 km

Obdelovalni center CNC

BUSELLATOS.MASTER H150

Klic

Stanje: rabljeno, Leto izdelave: 1996, Funkcionalnost: popolnoma funkcionalen, dolžina obdelovanca (maks.): 2.800 mm, širina obdelovanca (maks.): 1.300 mm, višina obdelovanca (maks.): 150 mm, skupna višina: 2.400 mm, skupna dolžina: 6.000 mm, skupna širina: 4.600 mm, skupna masa: 5.500 kg, CNC stroj za obdelavo lesa Busellato Super Master H150

Letnik: 1996

Še vedno priključen v delavnici

- Glavni motor 6,6 kW, vpenjalo ISO 30

- Izmenjevalec orodij za 3 pozicije

- Vrtalna enota 2,2 kW, 29 navpičnih + 6 vodoravnih vreten

- Dodatna vodoravna enota s 4. osjo, 360 stopinj, 3 kW, za 2 orodji (2 spiralna rezkarja ali 1 spiralni rezkar + krožna žaga)

Lhedpfx Abex R Tr Ujbob

- Delovna miza z 8 prečkami, 24 vakuumskih priseskov

- Vakuumska črpalka Becker 160 m3/h

Mali oglas

Italija

Italija

364 km

VERTIKALNI OBDELOVALNI CENTER

Hyundai WIAF-600D

Klic

Stanje: generalkompletno obnovljen (rabljeno), Leto izdelave: 2018, Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 800 mm, pomik osi Y: 600 mm, pomik po osi Z: 600 mm, hitro pomikanje X-os: 42.000 m/min, hitri pomik os Y: 42.000 m/min, hitri pomik na osi Z: 42.000 m/min, proizvajalec krmilnikov: FANUC, model krmilnika: i-Series, BRAND: HYUNDAI-WIA

MODEL: F-600D

CATEGORY: VERTICAL MACHINING CENTRE (ROTARY PALLET)

YEAR OF MANUFACTURE: 2018

CNC CONTROL: FANUC i-SERIES

MACHINE WEIGHT: 10,000 kg

MACHINE DIMENSIONS: Length: 3,904 mm / Width: 3,970 mm / Height: 3,080 mm

Spindle

Spindle taper: ISO 40

Spindle speed: 8,000 rpm

Spindle motor power (cont./30 min): 15/18.5 kW

Working Capacity

X-axis travel: 800 mm

Y-axis travel: 600 mm

Z-axis travel: 600 mm

Spindle-table distance: 200 - 800 mm

Distance between column and spindle centre: 690 mm

Table

Table size: 2 x (900 x 650 mm)

Ledsxxl Egopfx Abbshb

Number of tables: 2

Table load capacity: 2 x 500 kg

Pallet change time: 8.5 sec

Feedrates

Rapid traverse (X / Y axes): 42,000 mm/min

Rapid traverse (Z axis): 42,000 mm/min

Tool Changer

Tool holder: BT-40

Tool magazine capacity: 30 stations

Maximum tool diameter (adjacent/non-adjacent tools): Ø 90 / Ø 150 mm

Maximum tool length: 300 mm

Maximum tool weight: 8 kg

Accessories

Chip conveyor

Coolant collection tank with pumps

High-pressure coolant pump through spindle

Spindle line air conditioning unit

Manuals, electrical diagrams, and CE Declaration

This model stands out from the others you provided as it is a Vertical Machining Centre equipped with a Rotopallet system (two separate tables) and offers a very high rapid traverse rate of 42,000 mm/min.

Mali oglas

Budapest

Budapest

349 km

Vertikalni obdelovalni center

DMG MoriMilltap 700

Klic

Stanje: zelo dobro (rabljeno), obratovalne ure: 4.920 h, Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 700 mm, pomik osi Y: 420 mm, pomik po osi Z: 380 mm, hitro pomikanje X-os: 60 m/min, hitri pomik os Y: 60 m/min, hitri pomik na osi Z: 60 m/min, hitrost pomika os X: 60 m/min, hitrost podajanja osi Y: 60 m/min, hitrost podajanja os Z: 60 m/min, nazivna (navidezna) moč: 16 kVA, proizvajalec krmilnikov: Siemens, model krmilnika: 840D SL, obremenitev mize: 300 kg, največja hitrost vretena: 18.000 obr/min, nos vretena: BBT Big+, število mest v zalogovniku orodij: 25, Oprema: dokumentacija / priročnik, Stroj DMG Mori Milltap 700 naprodaj, v novem stanju. Krmiljenje Siemens 840 D SL. Stroj smo kupili zaradi majhnih prostorskih zahtev, 18.000 vrtljajev vretena, hitre menjave orodij in hitrega pomika 60 metrov na minuto. Stroj je mogoče ogledati in preizkusiti pod elektriko. Pomagamo pri pakiranju in nakladanju na tovornjak. 2x avtomatska vrata za robote. 40 bar notranje hlajenje, filtrirni sistem. Pripravljen za 4. in 5. os (Lehman). Heidenhain linearna merila na vseh oseh. Renishaw merilni sistemi. Transporter za odrezke. 4-kanalni hidravlični vpenjalni sistem. Dokumentacija.

Lhjdpfjxghpwox Abbob

Mali oglas

Nemčija

Nemčija

509 km

Univerzalni CNC obdelovalni center

AXAVPC 40 U

Klic

Stanje: rabljeno, Leto izdelave: 2003, Univerzalni CNC obdelovalni center

Proizvajalec: AXA

Tip: VPC 40 U

Leto izdelave: 2003

CNC krmilje: Heidenhain TNC 430

Pomiki: X/Y/Z = 2.300 x 1.200 x 600 mm

NC rotacijska miza mere: 1.100 x 1.100 mm

Fiksna miza mere: 1.100 x 1.100 mm

Lsdowwt Nmjpfx Abbehb

Vpenjalno držalo: SK40

Revolver za orodje: 60 mest

Hitrost vrtenja: 10.000 vrt/min

Teža: pribl. 20 t.

Mali oglas

Nemčija

Nemčija

509 km

CNC obdelovalni center

UnverzagtUVA 550 Plus

Klic

Stanje: rabljeno, Leto izdelave: 2012, CNC obdelovalni center

Proizvajalec: Unverzagt

Tip: UVA 550 Plus

Leto izdelave: 2012

Krmiljenje: Siemens 828D

Obratovalne ure: pribl. 3.000

Pomiki X/Y/Z: 600 x 400 x 500 mm

Orodni postaji: 20

Držalo za orodje: SK40

Območje vrtljajev vretena: 10.000 obr./min

Brezžična tipala Hexagon

Transporter za ostružke

Ledpjwv Tm Nofx Abbjhb

Hladilnik vretena

IKZ (notranji hladilni sistem)

21126ä

Mali oglas

Brno-město

Brno-město

361 km

Vertikalni obdelovalni center

HwacheonVesta 1000 12K

Klic

Stanje: dober (rabljeno), Leto izdelave: 2016, In good technical condition and fully functional.

Year of manufacture: 2016.

Machine includes 4-axis TSUDAKOMA, workpiece measuring probe, and tool measuring probe.

Axis travels (X/Y/Z): 1,000 / 550 / 500 mm

Distance from table surface to spindle face: 130 - 630 mm

Axis guide: linear rolling LM

Table working area: 1,100 x 502 mm

Table load capacity: 700 kg

Table surface configuration: 5x T-slot (width 18 mm, spacing 80 mm)

Spindle maximum speed: 12,000 rpm

Spindle power (10 min./continuous): 18.5 / 11 kW

Rapid traverse (X/Y/Z): 36/36/30 m/min

Feed rate (X/Y/Z): 1 – 24,000 mm/min

Feed motor (X/Y/Z): 1.8 / 1.8 / 3.0 kW

Automatic tool changer

Tool taper: BT40

Pull stud: MAS P40T-1 (45°)

Number of tool stations: 24

Max. tool diameter: Ø 80 / Ø 150 mm (without adjacent tool)

Max. tool length/weight: 300 mm / 8 kg

Tool-to-tool change time: 2.5 s

Chip-to-chip change time: 4.3 s

Magazine and changer disk design with rotating arm

Total connected load: 30 kVA

Tank capacity for spindle lubrication/cooling: 6 / 20 l

For coolant emulsion: 380 l

Machine dimensions – height: 2,670 mm

Footprint (length x width): 3,335 x 2,200 mm

Weight: 6,500 kg

Control system: Fanuc 0i-MD

Spindle air blast

Machine setting elements

Machine safety enclosure

Swarf conveyor in working area

Cooling system

Safety door

Lodpfx Aox Tti Sebbjhb

Ethernet interface

Mali oglas

Nemčija

Nemčija

509 km

CNC obdelovalni center

SIGMAZENIT 3-PALLET

Klic

Stanje: rabljeno, Leto izdelave: 1999, CNC Machining Center

Manufacturer: Sigma

Model: ZENIT 3-PALLET

Year of manufacture: 1999

CNC control: Heidenhain TNC 426

Travel axis X/Y/Z: 1,000 x 500 x 550 mm

Measuring system: optical rotary encoder

Machining performance:

Achieved performance in steel 60-70 kg/mm²

Drilling: 50 mm

Tapping: 36 mm

Material removal rate in milling max.: 850 cm³/min

Rapid traverse and working feed X/Y: 24,000 mm/min

Rapid traverse and working feed axis Z: 15,000 mm/min

Chain magazine with 2 directions of travel

Tool stations: 41 (optionally 51)

Tool selection: RANDOM

Automatic tool changer: double gripper change arm

Tool holder: 40 DIN 69871-A

Diameter of adjacent tools: 85 mm

Diameter of alternating tools: 125 mm

Max. tool length: 350 mm

Max. tool weight: 6 kg

Tool change time in sec.: approx. 3

Chip-to-chip time in sec.: approx. 5

Spindle speed: 40–12,000 rpm

Max. power: 25 kW

Gear stage change: electronic

Cooling system

Pallet changer unit

Number of pallets: 2

Standard surface: 1,000 x 500 mm

T-slots: 5x18 mm

T-slot center distance: 100 mm

Max. load capacity: 700 kg

Pallet change time: approx. 25 s

Clamping system: hydraulic

Dimensions (W x D approx.): 4,154 x 4,400 mm

Max. height approx.: 3,010 mm

Height without Z axis motor approx.: 2,660 mm

Height pallet/floor approx.: 1,075 mm

Connected load: 32 kW

Voltage: 400 V

Coolant pump delivery rate: 100 l/min

Coolant tank capacity: approx. 220 l

Work area lighting: Halogen 24V

Machine weight approx.: 9.8 t

20126

Lhsdpjyazqvofx Abbsb

Mali oglas

Sternenfels

Sternenfels

563 km

Vertikalni obdelovalni center

SpinnerVC 750

Klic

Stanje: zelo dobro (rabljeno), Leto izdelave: 2019, obratovalne ure: 5.500 h, Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 750 mm, pomik osi Y: 460 mm, pomik po osi Z: 460 mm, hitro pomikanje X-os: 36 m/min, hitri pomik os Y: 36 m/min, hitri pomik na osi Z: 36 m/min, proizvajalec krmilnikov: Siemens, model krmilnika: Sinumerik 840 D, širina mize: 410 mm, dolžina mize: 900 mm, obremenitev mize: 350 kg, vrtljajska hitrost (min.): 10 obr/min, največja hitrost vrtenja: 12.000 obr/min, skupna masa: 4.000 kg, hitrost vretena (min.): 10 obr/min, največja hitrost vretena: 12.000 obr/min, število vreten: 1, število mest v zalogovniku orodij: 24, Vertikalni obdelovalni center Spinner VC 750 iz učnega obrata

Leto izdelave: 2019

Krmilnik: Sinumerik 840D

Tehnični podatki

Hitrost vretena: 10 - 12.000 min-1

Pogonska moč: 11/17 kW

Vpenjalno steblo orodja: SK 40

Število mest v zalogovniku: 24

Velikost mize: 900x410 mm

Hodi osi:

X-os: 750 mm

Y-os: 460 mm

Z-os: 460 mm

Lhjdpfjya H Tcjx Abbsb

Dodatna oprema:

Elektronsko ročno kolo

KSS sistem

Transporter za ostružke

Priprava za 3D-gumb – sprejemnik prisoten

Mali oglas

Częstochowa

Częstochowa

602 km

Vertikalni obdelovalni center

HaasVM-6HE

Klic

Stanje: zelo dobro (rabljeno), Proizvajalec: Haas

Model: VM-6HE

Serijska številka (SN): 1067464

Osnosti: 3-osni CNC obdelovalni center

Vpenjalo vretena: SK40

Pomiki osi (X/Y/Z): 1.625 × 812 × 764 mm

Miza: vpenjalna miza

Oprema:

Lsdpfjxywiyjx Abbehb

transporter za ostružke

avtomatski menjalec orodij (ATC)

magazin orodij: 24 pozicij

Mali oglas

Częstochowa

Częstochowa

602 km

Vertikalni obdelovalni center

HaasVM-3HE

Klic

Stanje: zelo dobro (rabljeno), Proizvajalec: Haas

Serijska številka: 1059169

Vpenjalo vretena: SK40

Pomiki osi (X/Y/Z): 1.016 × 660 × 635 mm

Dodatna oprema:

transportni trak za odrezke

vpenjalna miza

Ljdpfxexywh Aj Abbshb

avtomatski menjalec orodij (ATC)

magazin orodij: 24 pozicij

Mali oglas

Nattheim

Nattheim

457 km

CNC obdelovalni center

SCM morbidelliM 400

Klic

Stanje: rabljeno, Leto izdelave: 2016, MORBIDELLI AUTHOR M400

KEY FEATURES

5-AXIS MACHINING UNIT "PRISMA": QUALITY AND PRODUCTIVITY AT THE HIGHEST LEVEL

Lhedpfsxnldbox Abbob

SOFTWARE XILOG MAESTRO: EXTREMELY SIMPLE PROGRAMMING

"MATIC" WORKTABLE: ONE POSITIONING FOR MULTIPLE OPERATIONS

TECHNICAL DATA AUTHORM400

AXES

Working area X-axis (infeed side): 3,680 mm

Working area Y-axis (max. workpiece size on rear stops): 1,680 mm

Workpiece passage Z / Number of Z axes: 170 mm / 1

Workpiece length in pendulum operation: 1,650 mm

Travelling speed X-Y axes Pro-Speed: 85 m/min

Z-axis speed: 30 m/min

INSTALLATION

Installed power: 62 - 82 KVA

Compressed air requirement: 400 NL/min

Extraction air requirement: 4,430 m³/h

Extraction air velocity: 25 m/s

Extraction outlet diameter: 250 mm

GENERAL FEATURES

CNC-controlled drilling and milling centre in gantry design with workpiece supports, capable of:

- Vertical drilling on panel surface

- Horizontal drilling on all four workpiece edges

- Grooving with disc cutter

- General 3-4-5 axis milling operations

MACHINE STRUCTURE

The base is a monolithic construction of thick-walled steel, additionally reinforced across the entire bed with welded stiffeners, ensuring extreme stability. The table shape, with a large base, is key to guaranteeing long-term precision and stability. The machine’s layout allows the user optimal workflow with minimal footprint. The mobile gantry is constructed as a solid monoblock and moves in the X-axis on prism-ground guides with ball-bearing carriages. The machining unit is also mounted on prism-ground guides and ball-bearing carriages on this mobile unit.

AXIS MOVEMENT

All axes travel on large-section prism linear guides with ball-bearing shoes for maximum contact area, ensuring optimal running even at the highest speeds and accelerations. The precise and rapid positioning of the moving gantry (X-axis) is achieved with helical rack and pinion drive. Large-section ball screws ensure precise positioning of the machining unit along the moving gantry (Y and Z axes).

DRIVES, MOTORS, AND INVERTERS

Perfect mechanical dynamics and highest positioning accuracy are ensured by high-quality drives and brushless motors capable of speeds up to 90 m/min, while maintaining optimum finish quality.

CONTROL

The control system consists of a numerical control unit for milling and drilling operations with the "Xilog Maestro" graphic user interface based on Windows 7 Office OS, 17" LCD color display, QWERTY keyboard, swiveling operator panel, and machine operator interface with Xilog Maestro software.

Xilog Maestro Features

Programming:

- Parametric graphical programming

- Import of DXF files (2D; geometries: "SPLINE", "POLYLINE 3D", line or circle interpolation in three axes, linear in space, spiral in the chosen plane)

- Supported programming with graphical and syntax aides for drilling and milling operations

- Automatic optimization of drilling operations and tool-change cycles

- Option to shift panel zero-point for drilling on inclined or curved panel edges

Mali oglas

Zona Industriale "scerne"

Zona Industriale "scerne"

398 km

CNC OBDELOVALNI CENTER ZA OBREZOVANJE ROBOV

HOMAGBAZ 20/50/14/G

Klic

Stanje: zelo dobro (rabljeno), Delovno središče z enoto za robno lepljenje za ravne in ukrivljene plošče

Lhodpfx Aslpf E Ujbbeb

- 4-osni elektro vreteno z vpetjem HSK F63, za natančne in vsestranske obdelave

- Avtomatski revolverski magazin za orodja z 12 mesti, za hitro menjavo orodja

- Integrirana vrtalna glava, idealna za vrtanje v različne materiale

- Enota za robno lepljenje za natančno nanašanje robnega traku na ravne in ukrivljene plošče

- Magazinski sistem za robne trakove s 3 pozicijami, za učinkovito upravljanje različnih vrst trakov

- Vakuumska črpalka za varno fiksiranje plošče med obdelavo

Mali oglas

San Giovanni Al Natisone

San Giovanni Al Natisone

125 km

2005 BIESSE ROVER B 4.40 FT 3-osni CNC obdelovalni center

BIESSEROVER B 4.40 FT

Klic

Stanje: rabljeno, Leto izdelave: 2005, 2005 BIESSE ROVER B 4.40 FT CNC obdelovalni center s 3 osmi

Tehnične značilnosti na zadnji fotografiji

Lhodpswmdynofx Abbjb

Delovne ure stroja: 45.343

Ure v avtomatskem načinu (delo): 27.267

Mali oglas

Češka republika

Češka republika

359 km

Vertikalni obdelovalni center

HurcoVMX 50t

Klic

Stanje: rabljeno, Funkcionalnost: popolnoma funkcionalen, potovalna razdalja osi X: 1.270 mm, pomik osi Y: 660 mm, pomik po osi Z: 610 mm, Parametri stroja:

Pomiki po ose X, Y, Z:

1270 x 660 x 610 mm

Lsdpfjyarahsx Abbjhb

Vpenjalna površina mize:

1500 x 660 mm

Opis:

Stroj je v dobrem tehničnem stanju, po predhodnem dogovoru je možen preizkus. Podprti sistemi: MAX4 z WinMax v8. Jeziki upravljanja v celoti v slovenskem jeziku. 3D simulacija: da. Vrsta programiranja: Dialog in NC.

MIZA

Dimenzije mize: 1500 x 660 mm

T-utori: 6 x 18 mm

Maks. obremenitev mize: 1350 kg

Razdalja čela vretena do mize: 150 – 760 mm

POMIKI

Os X: 1270 mm

Os Y: 660 mm

Os Z: 610 mm

Os A: 360°

VRETENO

Maks. vrtljaji vretena: 12.000 min⁻¹

Moč vretena: 18 kW

Navor: 237 Nm

Vretenasti stožec: SK 40

MAGAZIN ORODIJ

Število orodij: 40

Maks. premer orodja: 75 / 125 mm

Maks. teža orodja: 7 kg

POMIKI

Hitri pomik X/Y/Z: 30 / 30 / 20 m/min

Delovni pomik X/Y/Z: 15 m/min

DRUGI PODATKI O STROJU

Dimenzije Š x G x V: 3250 x 2220 x 2950 mm

Teža: 9400 kg

Mali oglas

Friesenheim

Friesenheim

593 km

Vertikalni obdelovalni center

DMG MORIDMU 65 Monoblock

Klic

Stanje: zelo dobro (rabljeno), Leto izdelave: 2015, obratovalne ure: 7.110 h, Funkcionalnost: popolnoma funkcionalen, DMG DMU 65 Monoblock 5-osni obdelovalni center (2015)

Proizvajalec: DMG

Tip: DMU 65 Monoblock

Leto izdelave: 2015

Stanje: rabljeno, zelo dobro, še vedno v proizvodnji.

Delovne ure: 21.336 h

Lhodpfxjx Iwb Io Abbob

Ure na vretenu: 7.112 h

Krmiljenje: Heidenhain iTNC 530

X-os: 735 mm

Y-os: 650 mm

Z-os: 560 mm

Vpenjanje orodja: SK40

Hitrost vretena: 10.000 obr./min

Transporter odrezkov

Visokotlačno notranje hlajenje 40 bar

Trakasti filter

3D tipalo

Dokumentacija

Dodatna oprema po izbiri.

Mali oglas

Nattheim

Nattheim

457 km

CNC obdelovalni center

MorbidelliAuthor 853

Klic

Stanje: rabljeno, Leto izdelave: 2006, Delovno območje X-Y-Z: 5300 x 1700 x 180 mm Dolžina hoda X-Y-Z: 6040 x 1810 x 280 mm Vrtalna glava s 30 + 8 vreteni Hitrost vrtenja: 6000 1/min Moč: 2,2 kW Avtomatsko centralno mazanje Delovna miza TV z 10 podporniki L=1500 4 delovna polja 2 križna laserja Vakuumska črpalka 250 m³/h PC nadzor Windows Vertikalna rezkalna enota ISO 30 7,5 kW z menjalcem orodja RAPID 14 in vektorsko osjo Dodatni vrtalni agregat (E-os) Dongle za programsko opremo XILOG Lokacija skladišča: Nattheim

Lhsdpsx Twd Hjfx Abbob

Mali oglas

Nattheim

Nattheim

457 km

CNC obdelovalni center

SCMTECH Z 25

Klic

Stanje: rabljeno, Leto izdelave: 2007, Workspace: 2780 x 1140 mm (vertical milling), 2500 x 950 mm (horizontal drilling). Travel X-Y: 2980 x 1271 mm. Z-axis travel: 200 mm. Clearance height: 180 mm. The base structure is a monolithic design made of thick-walled steel, reinforced throughout the entire machine bed by fully welded triangular plates, resulting in extreme rigidity. The triangle shape with a wide base, used for all load-bearing components, is the secret to ensuring lasting precision and stability. The machine layout provides the operator with an optimal workflow while requiring minimal space. This base structure offers the machining unit a balanced and secure foundation with outstanding load distribution.

The mobile aggregate support is constructed as a solid monoblock. It travels along the X-axis on precision-ground linear guides by means of recirculating ball bearing carriages. The machining unit is mounted to the mobile support via precision-ground linear guides and ball bearing carriages as well.

Description of aggregates and standard accessories:

Drilling unit: Drilling head with 10 + 4 spindles

· 6 individually selectable vertical spindles in X

· 4 individually selectable vertical spindles in Y

· 2 horizontal spindles in X (1+1)

· 2 horizontal spindles in Y (1+1)

· Speed: 4,000 rpm

· Power: 2.2 kW

· Pitch: 32 mm

· Chuck: M10 with 11 mm locating pin

· Extraction port: D = 160 mm

Vertical milling unit (Position 2)

· Tool holder: HSK 63F

· Speed: 1,500 - 24,000 rpm, variably adjustable via inverter

· Motor output: 4.4 kW (6 HP) from 12,000 rpm (S1)

· Clockwise / counterclockwise rotation

· Ceramic bearings

· Delivery includes: 4 tool holders (right), without collets

Tool changer

· Side-mounted tool magazine for 7 tools (TR7), fully enclosed to protect against chips

· 7 tool stations for HSK 63F holders in sequence

· Max. tool diameter: D = 120 mm

· Max. weight per holder: 4.5 kg

· Max. total tool weight: 20 kg (TR7)

· Angle heads can be accommodated

Horizontal milling unit (Position 1)

Horizontal unit with two opposing outputs for milling and grooving.

· Speed: 9,000 - 18,000 rpm, stepless via inverter

· 1 output for collet 3-20 mm (ER 32)

· 1 output for saw/collet 3-12 mm (ER20) (for saw blade D = 120 mm / bore 50 mm)

· Motor output: 3 kW (4 HP)

· Max. tool diameter, front milling: 20 mm

· Max. tool length, front milling: 110 mm

· Max. tool diameter, rear milling: 12 mm

· Max. tool length, rear milling: 80 mm

· Max. saw blade diameter: 100 mm

· Saw blade bore (ER 32): 50 mm

· Saw blade spindle diameter (ER 20): 12 mm

Worktable

The worktable is designed to guarantee the operator maximum freedom of movement. The quick vacuum clamping system ensures maximum flexibility for precise positioning and optimal holding of workpieces.

· 4 supports, 900 mm, infinitely variable adjustment in X

Ljdex Twdyepfx Abbshb

· 8 round vacuum pods D = 110 mm, infinitely adjustable in Y (2 per support)

· 2 stops in X (1 left / 1 right)

· 1 stop in Y per support (total: 6)

· The retractable reference stops are CNC-controlled

· Supplied: 4 plug-in adapters for suction pads

· Standard feature: pendulum (dual-zone) operation

Axis movement

The drive system in X, Y, and Z uses ground recirculating ball screws of the highest precision class. The X-axis ball screw is positioned exactly along the centerline...

Mali oglas

Nattheim

Nattheim

457 km

CNC obdelovalni center

SCMZ1 26A

Klic

Stanje: rabljeno, Leto izdelave: 2011, · Working area: 2,550 x 1,067 mm

· Travel range X-Y: 2,980 x 1,450 mm

· Z-axis stroke: 150 mm

· Clearance height: 120 mm

Drilling unit F14:

Drill head with 8 + 6 spindles

· 5 individually selectable vertical spindles in X

· 3 individually selectable vertical spindles in Y

· 4 horizontal spindles in X (2+2)

· 2 horizontal spindles in Y (1+1)

· Speed: 4,000 rpm (6,000 rpm optionally available)

· Power: 2.2 kW

· Grid: 32 mm

· Drill chuck: M10 with 11 mm fit

· Pneumatic feed stroke: 60 mm

Grooving saw unit in "X":

· Integrated in the drill head

· Grooving saw blade up to max. 120 mm diameter

Main milling unit:

· Tool holder HSK 63F

· Speed 1,500 – 24,000 rpm, infinitely variable via inverter

· Motor power 6.6 kW (9 HP) from 12,000 rpm (S1)

· Motor power 7.5 kW (10 HP) from 12,000 rpm (S6)

· Clockwise/counterclockwise rotation

· Ceramic bearings

· Prepared for angle drive use

Tool changer TR10

Automatic side tool changer for 10 tools.

· Number of tool slots: 10

· Max. tool diameter: 120 mm

· Max. tool weight: 4.5 kg

· Max. total tool weight: 28 kg

A central extraction port combines all machining units to a single connection with D = 200 mm. This reduces the required extraction capacity to approx. 3,200 m³/h.

Worktable TVF

The worktable is designed to guarantee the operator maximum freedom of movement. The quick-release vacuum system ensures maximum flexibility, precise positioning, and optimal clamping of workpieces.

· 4 TVF supports L = 1,100 mm, continuously adjustable in X

· 12 TVF vacuum cups 120 x 120 mm, continuously adjustable in Y

· 2 stops in X (1 left / 1 right)

· 1 stop in Y per support (total 4 pcs.)

· The retractable reference stops are CNC-controlled

Automatic central lubrication

The correct amount of grease is distributed via an electronic CNC control unit (X, Y, Z axes)

Vacuum system (basic machine):

· Vacuum pump: 90 m³/h

· Power: 2.2 kW

· Max. vacuum (at pump): 0.9 bar

PROGRAMMING SYSTEM XILOG PLUS

Software features:

- Import of DXF files

- Import of ASCII files

- User interface in operator’s native language

Safety devices with bumpers

Machine technical data

· Total connected load max.: 18 kW

· Recommended fuse: 64 A

· Supply: 400 V 50-60 Hz

· Compressed air: 6-7 bar

· System pressure (recommended): 8 bar

· Compressed air consumption: 200 Nl/min

· Central extraction port diameter: 200 mm

· Extraction speed: 30 m/sec

· Air consumption (central extraction): 3,200 m³/h

· Vacuum: 3,000 Pascal

· Weight: approx. 2,500 kg

Lhjdpjx Twc Nefx Abbjb

Remote control of machine functions

6 TVF supports L=1,100mm and 18 vacuum cups 120x120 mm

Cross laser for vacuum cup positioning

Two cross lasers mounted on the unit carrier facilitate easy positioning of the vacuum cups.

Location: Nattheim

Znak zaupanja

Prodajalci, certificirani pri Machineseeker

Mali oglas

Nattheim

Nattheim

457 km

CNC obdelovalni center

SCMTech Z27 C

Klic

Stanje: rabljeno, Leto izdelave: 2006, · Working area: 2,650 x 1,240 mm

· Travel range X-Y: 2,995 x 1,385 mm

· Z-axis travel: 200 mm

· Clearance height: 180 mm

The machine base structure is a monolithic design made of thick-walled steel. It is reinforced with welded triangular plates across the entire machine bed, providing exceptional stability. The use of the triangular shape with a broad base for load-bearing components is the key to long-lasting precision and stability. The layout of the machine allows the user to achieve optimal workflow while requiring minimal floor space. This design gives the processing unit a balanced and secure foundation with excellent load distribution.

The moving aggregate carrier is constructed from a solid monoblock. It is positioned in the X direction on prismatically ground guides via recirculating ball carriages. The processing unit itself is mounted on this mobile carrier, also on prismatic, ground guides and recirculating ball carriages.

Description of units and accessories (basic version)

Drilling unit:

Drill head with 12 + 6 spindles

· 7 individually activatable vertical spindles in X

· 5 individually activatable vertical spindles in Y

· 4 horizontal spindles in X (2+2)

· 2 horizontal spindles in Y (1+1)

· Speed: 4,000 rpm

· Power: 2.2 kW

· Grid: 32 mm

· Drill holder: M10 with 11 mm locating shoulder

Grooving saw unit in X:

· Integrated in the drill head

· Grooving saw blade up to max. 120 mm diameter

Ljdpfx Aox Twccobbohb

Main milling unit (position 2):

· Tool holder HSK 63F

· Speed 1,500 – 24,000 rpm, steplessly via inverter

· Motor power 4.4 kW (6 HP) from 12,000 rpm (S1)

· Motor power 6.6 kW (9 HP) from 12,000 rpm (S6)

· Right/left rotation

· Ceramic bearings

· Scope of delivery: 4 pcs. tool holders (right) without collet

Tool changer R8L

Automatic tool change system for 8 tools. Mounted on the rear aggregate carrier for rapid tool access.

· Number of tool places: 8

· Max. tool diameter: 120 mm

· Max. tool weight: 4.5 kg

· Max. total tool weight: 22 kg

· Holder for 1 angle gear

· Moves in X-direction

Horizontal milling unit (position 1):

Horizontal unit with two opposing outputs for milling and grooving.

· Speed 9,000 – 18,000 rpm steplessly via inverter

· 1 output for collets 3–20 mm (ER32)

· 1 output for saw/collet 3–12 mm (ER20) (For saw D=120 mm / bore 50 mm)

· Motor power 3 kW (4 HP)

· Max. milling diameter front: 20 mm

· Max. milling length front: 110 mm

· Max. milling diameter rear: 12 mm

· Max. milling length rear: 80 mm

· Max. saw blade diameter: 100 mm

· Saw blade bore (ER32): 50 mm

· Saw blade arbor diameter (ER20): 12 mm

Work table

The work table is designed to guarantee the operator maximum range of motion. The vacuum quick-clamping system provides maximum flexibility with precise positioning and optimal workpiece holding.

· 6 rails, 1000 mm, continuously adjustable pneumatically in X

· 12 vacuum cups, round, D = 110 mm, continuously adjustable in Y (2 pieces per rail)

· 2 stops in X (1 left / 1 right)

· 1 stop in Y per rail (total 6 pcs)

· The retractable reference stops are CNC-controlled

· Pendulum machining standard (2 working zones)

--- Other clamping systems available as options ---

Axis movement

The drive system in X, Y, and Z axes operates via ground recirculating ball screws of the highest precision class. The ball recirculation...

Mali oglas

Burgoberbach

Burgoberbach

476 km

Vertikalni obdelovalni center

DMGDMC 80 H Hi-Dyn RS4

Klic

Stanje: dober (rabljeno), Funkcionalnost: popolnoma funkcionalen, številka stroja/vozila: 288-40003902, potovalna razdalja osi X: 800 mm, pomik osi Y: 800 mm, pomik po osi Z: 800 mm, skupna višina: 2.500 mm, skupna dolžina: 5.000 mm, skupna širina: 3.500 mm, širina mize: 500 mm, dolžina mize: 630 mm, DMG DMC 80 H Hi-Dyn RS4

For sale: Horizontal Machining Center DMC 80 H hi-dyn RS4.

The machine is in good condition.

Technical Specifications:

Travel paths:

X-axis: 800 mm

Y-axis: 800 mm

Z-axis: 800 mm

Table Data:

Table size: approx. 630 × 500 mm

Max. workpiece weight: ~1,200–1,400 kg

Rotary table: 4th axis, 360° continuous

Spindle:

Direct drive, liquid cooled

Speed ranges:

Operating mode: 0–6,000 rpm

Setup mode: 0–800 rpm

Manual mode: 0–5,000 rpm

Max. speed: up to 8,000 rpm

Spindle power: approx. 20 kW

Torque: S1 – 100% duty cycle

Upon request, disassembly, loading, and Europe-wide transport can be organized for an additional fee.

Prices plus VAT

Lhsdpfx Asx Uq Saobbjb

Inspection possible by appointment. Contact us—our team is happy to assist you!

Trade-in or exchange possible!

Machinery Purchase / Sale

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINES AND MORE.

Are you looking for a high-quality yet cost-effective metalworking machine for your production? Or would you like to sell yours?

For more information or contact options, please visit our website.

Mali oglas

Burgoberbach

Burgoberbach

476 km

Vertikalni obdelovalni center

Exeron DigmaHSC 300

Klic

Stanje: dober (rabljeno), Leto izdelave: 2006, potovalna razdalja osi X: 415 mm, pomik osi Y: 340 mm, pomik po osi Z: 355 mm, hitro pomikanje X-os: 20 m/min, hitri pomik os Y: 20 m/min, hitri pomik na osi Z: 20 m/min, dolžina podajanja os X: 40.000 mm, proizvajalec krmilnikov: Heidenhain, hitrost vretena (min.): 42.000 obr/min, For sale: Vertical CNC Machining Center Exeron Digma HSC 300. The machine is in good condition.

Technical Data:

Machine type: Vertical CNC Machining Center

Year of manufacture: 2006

Control system: HEIDENHAIN

X-axis travel: 300 mm or 415–480 mm

Y-axis travel: 300 mm or 340 mm

Z-axis travel: 300 mm or 355–400 mm

Rapid traverse (X/Y/Z): Up to 20 m/min

Feed rate range: Up to 40,000 mm/min

Spindle speed: Up to 42,000 rpm, high-frequency spindle

Spindle taper: HSK-40E

Tool changer: 30 stations

Lhjdpjx Upy Nofx Abbeb

Max. workpiece weight: 500 kg

Total weight: 5,000 kg

Dimensions: 3,050 x 2,500 x 2,470 mm

Transport and loading can be organised across Europe for an additional fee upon request.

Prices are subject to VAT.

Viewing possible by appointment. Please contact us—our team is happy to assist you.

Part exchange or trade-in is possible!

Machinery Purchase / Sale

PURCHASE / SALE OF PRODUCTION & METALWORKING MACHINERY, AND MORE.

Are you looking for a high-quality yet cost-effective metalworking machine for your production? Or would you like to sell yours?

For more information or contact options, please visit our website.

Mali oglas

Madžarska

Madžarska

362 km

Vertikalni obdelovalni center

HurcoVMX84i

Klic

Stanje: pripravljen za uporabo (rabljen), Leto izdelave: 2015, Splošni podatki

Teža stroja 17000 kg

Miza

Obremenitev mize 2270 kg

Glavni pogon

Število osi 3

Hitrost vretena 12000 vrt/min

Moč motorja vretena 18 kW

Oznaka vpenjalnega stožca SK 40

Pomiki

Pomik po osi X 2135 mm

Pomik po osi Z 762 mm

Pomik po osi Y 865 mm

Orodja

Največja teža orodja 7 kg

Ta triosni stroj Hurco VMX84i je bil izdelan leta 2015. Opremljen je z nadzornim sistemom WinMax, velikostjo mize 2185 × 865 mm in največjo obremenitvijo mize 2270 kg. Stroj omogoča pomike 2135/865/762 mm in hitrost vretena do 12000 vrt/min. Vključen je 40-pozicijski avtomatski menjalnik orodij in hlajenje preko vretena. Če iščete kakovostne rezkalne zmogljivosti, razmislite o stroju Hurco VMX84i iz naše ponudbe. Za več informacij nas kontaktirajte.

Vrste uporabe

Rezkanje

Lodpfox Stlwox Abbohb

Olajšamo vam iskanje: "vertikalni cnc obdelovalni center"

Nove ponudbe prejmete takoj in brezplačno po e-pošti.

Iskalno nalogo lahko kadar koli preprosto končate.

Rabljeni Vertikalni Cnc Obdelovalni Center (22.412)

Zdaj preiščite celoten Machineseeker z več kot 200.000 rabljenimi stroji.Brskajte po najbolj priljubljenih poimenovanjih strojev:

- Avtomatski Stroj Za Varjenje

- Bar Obdelovalni Center

- Center Brusilni Stroj

- Centrirni Stroj Za Pnevmatike

- Cnc - Stroj Za Rezkanje

- Cnc Fräsen Center

- Cnc Rezkalni Center

- Cnc Rezkalni Stroj In Obdelovalni Center

- Cnc Rezkalni Stroj S Orodje Menjalec

Izvedite več zdaj

+44 20 806 810 84

+44 20 806 810 84

Objavite oglas zdaj

*na oglas/mesec