Hank nakup rabljenega (4.440)

Razvrsti rezultate

- Najnižja cena Najvišja cena

- Najnovejši oglasi Najstarejši oglasi

- Najkrajša razdalja Največja razdalja

- Najnovejše leto izdelave Najstarejše leto izdelave

- Zadnja posodobitev Najstarejša posodobitev

- Proizvajalci od A do Ž Proizvajalec od Z do A

- Pomembnost

- Najnižja cena

- Cena

- Najvišja cena

- Cena

- Najnovejši oglasi

- Datum objave

- Najstarejši oglasi

- Datum objave

- Najkrajša razdalja

- Razdalja

- Največja razdalja

- Razdalja

- Najnovejše leto izdelave

- Leto izdelave

- Najstarejše leto izdelave

- Leto izdelave

- Zadnja posodobitev

- Nazadnje posodobljeno

- Najstarejša posodobitev

- Nazadnje posodobljeno

- Proizvajalci od A do Ž

- Proizvajalec

- Proizvajalec od Z do A

- Proizvajalec

- Oznaka od A do Ž

- Oznaka

- Oznaka od Z do A

- Oznaka

- Model od A do Ž

- Model

- Model od Z do A

- Model

- Najnižja referenca

- referenca

- Najvišja referenca

- referenca

- Najkrajši obratovalni čas

- Obratovalni čas

- Najdaljši čas obratovanja

- Obratovalni čas

- Pomembnost

- Pomembnost

Mali oglas

Schwanberg

Schwanberg

69 km

Vijačni kompresor

AGRE / ALUPSONETTO 9

Klic

Stanje: novo, Screw compressor with refrigerant dryer

Belt-driven. Space-saving. Cost-effective.

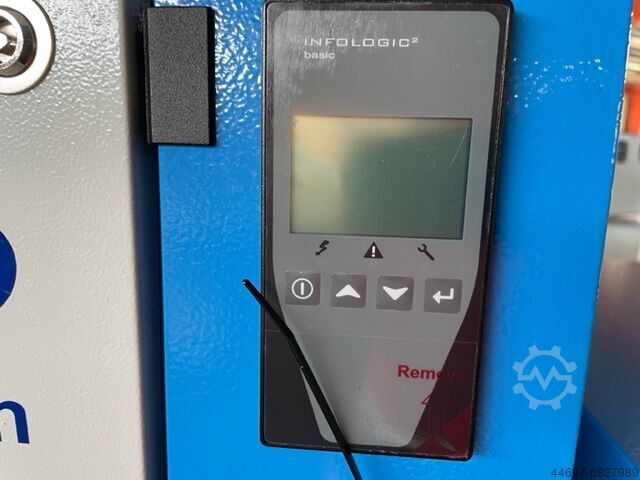

Easy operation thanks to Infologic² Basic control system.

Efficient compressor stage. Perfect solution for industrial and craft enterprises.

Convincing compressed air quality.

Detailed features:

Compression concept: Oil-lubricated screw compressor

Gtsdpfx Afewm Ih Aoqet

Cooling: Air-cooled, efficient cooling system

Drive: Efficient IE3 motor, belt drive

Control: Fixed speed

Controller: Infologic² Basic control unit

Refrigerant dryer: Integrated, refrigerant R513A

Receiver: Horizontal, painted, manufactured according to AD2000

Performance data:

Free air delivery at operating pressure 9.5 bar: 0.98 m³/min

Operating pressure min. / max.: 5.5 / 10.0 bar

Total power consumption at 9.5 bar / full load: 9.6 kW

Motor nominal power; IP55: 7.5 kW

Oil quantity: 3.2 liters

Pressure dew point of dryer (20°C 100% RH): approx. +3 °C

Installation data:

Ambient conditions min. / max.: 1 / 46 °C

Δ T over cooling medium temperature: 2 °C

Cooling air requirement: 756 m³/h

Free fan pressure: 30 Pa

Sound level: 68 dB(A)

Voltage / PH / Frequency: 400 / 3 / 50 V / Ph / Hz

Dryer power rating (230V/50Hz): 0.27 kW

Dimensions and weight:

Length x Width x Height: 1540 x 665 x 1350 mm

Weight: 240 kg

Compressed air outlet: G 1/2" female thread

Air receiver volume: 270 liters

INCLUDED OPTION:

Aftercooler C43 MINI (reduces condensate formation to a minimum)

Mali oglas

Waiblingen

Waiblingen

519 km

Center stružnica

WEILERCONDOR VC plus

Klic

Stanje: novo, Leto izdelave: 2025, CONDOR VC plus

The new standard in conventional precision lathes.

A high-quality, powerful, and energy-efficient precision lathe designed for high productivity in production and toolmaking, as well as in training and education environments.

Premium quality, energy efficiency, precision, and universal application in production, training, and continuous education. It stands out thanks to:

- Future-oriented technology

- Maximum accuracy

- Long service life

- User-friendly ergonomics

- Minimal footprint

- Extensive range of accessories

The consistent and innovative further development of the proven Condor series offers an economical and intelligent solution for your daily operations.

Technical Data:

WORKING RANGE

Center height: 180 mm

Swing diameter over bed: 360 mm

Swing diameter over cross slide: 190 mm

Distance between centers: 800 mm

SPINDLE

Spindle nose DIN 55027 / DIN ISO 702-3: Size 6

Spindle bore: 57 mm

Spindle front bearing diameter: 90 mm

MAIN DRIVE

Power rating 60%/100% duty cycle: – / 10.5 kW

Spindle speed range: 25 – 4,000 rpm

Number of speeds: stepless

FEED RANGE

Number of feeds: stepless

Longitudinal: 0.01 – 6 mm/rev

Cross: 0.003 – 2 mm/rev

THREADING RANGE

Metric threads: 0.1 – 20 mm

TAILSTOCK

Quill diameter: 50 mm

Quill stroke: 110 mm

Internal taper DIN 228: MK 3

ACCEPTANCE ACCURACY: DIN 8605

Equipped with WEILER screen display WTS 15 VC plus

- Large, clear 15" touchscreen, rotatable and tiltable, resolution 1366 x 768

- Menu navigation via swipe gestures

- Operating functions accessible via app manager

- Operator panels freely configurable, placeable, and scalable

- Drawings/sketches import from PDF files via USB interface, individually zoomable

- Video-supported machine maintenance

- Context-sensitive help menu

Gjdpfoqwipnsx Afqett

(replaces WEILER VC plus screen display)

The machine is located at our showroom in 71334 Waiblingen-Beinstein and is available immediately. For detailed equipment information, please contact us.

Mali oglas

Cantù

Cantù

455 km

Klasični stružnica

MVM - ITALYT 1500

Klic

Stanje: dober (rabljeno), Kód: 0242

Znamka: MVM - ITALIJA

Model: T 1500 - CE standard

Profesionalni stružnica za les s kopirno napravo za les, mavec, kompozitne materiale in različne druge materiale – CE standard

Tehnični podatki:

Enofazni motor 220 V – 2,5 kW

Kopirna naprava: Kopirna naprava je enota, nameščena na zadnji strani postelje stroja. Omogoča reprodukcijo oblik s pomočjo lesenih vzorcev ali kovinskih šablon zaradi moderne izvedbe. Je praktično in enostavno vodljivo orodje, ki omogoča veliko prihranek časa tudi pri serijski ali masovni proizvodnji. Pomik se izvaja z udobnim obračanjem kolesa, ki se nahaja na sprednji strani stroja.

Razdalja med konicama: 1500 mm

Višina konice: 220 mm

Orodni nosilec

Število obratov vretena: 4 hitrosti

Stožec vretena št. 2

Gedpfx Afjxykwkoqjtt

Kontra konica št. 3

Skupne dimenzije (dxšxv): 2350 x 650 x 1200 mm

Teža: 325 kg

Izvedite več zdaj

+44 20 806 810 84

+44 20 806 810 84

Objavite oglas zdaj

*na oglas/mesec

Mali oglas

Pfeffenhausen

Pfeffenhausen

364 km

Kombi z visokim stropom

IVECODaily Koffer Auto *Luftfederung* Kasten

Klic

Stanje: rabljeno, prevoženi kilometri: 129.000 km, moč: 78 kW (106,05 KM), prva registracija: 02/2012, vrsta goriva: dizel, skupna masa: 3.500 kg, vrsta prenosa: samodejen, emisijski razred: Euro 4, Oprema: ABS, centralno zaklepanje, elektronski program stabilnosti (ESP), filter saj, Net sale price: €5,880

Iveco Daily

First registration: 02/2012

Mileage: 129,000 km

TÜV (MOT): 02/2026

For enquiries:

VAT deductible.

At least 50 units in stock

----Please no emails / Emails can only be processed sporadically due to time constraints! Thank you for your understanding.

---- Opening hours and further information:

Inspection and purchase without appointment possible:

MON - THU: 9:00 am to 4:00 pm

FRI: 9:00 am - 1:00 pm

Gtsdpow H H Eyjfx Afqot

SAT: 9:00 am - 12:00 pm

Address:

Tabakried 11

84076 Pfeffenhausen

Germany

For enquiries:

Christian Hirsch

Please, try several times as we are often in customer meetings.

----Full service history / maintained: yes

Emission class: EURO 4

Environmental badge: green

Previous owner(s): 1

VAT deductible: yes

Emission class: Euro 4 = Green badge

- With / without air suspension in stock

- Reversing camera - LED

- Interior lighting with motion detector

- Cargo area length: 4.35 m

- Cargo area width: 2.05 m

- Cargo area height: 2.07 m

Front passenger seat foldable

Interior features:

Cupholder,

Power steering

Exterior features:

Sliding door,

Electrically adjustable & heated side mirrors,

Central locking incl. remote control,

Electric windows - front

Technology:

Outside air temperature display

On-board computer

Safety & Environment:

Driver's airbag,

Immobilizer

ABS

ESP

Traction control

Particulate filter

For enquiries:

Christian Hirsch

Please try several times as we are often in customer meetings.

Further offers at /

Further offers at /

Equipment details were determined using a VIN query; technical errors may occur

Opening hours and further information:

Inspection and purchase without appointment possible:

MON - THU: 9:00 am to 4:00 pm

FRI: 9:00 am - 1:00 pm

SAT: 9:00 am - 12:00 pm

Address:

Tabakried 11

84076 Pfeffenhausen

Germany

---- Information provided online is a non-binding description. They do not constitute guaranteed characteristics. The seller is not liable for typing or transmission errors / changes / entry errors. Subject to errors and prior sale.

Mali oglas

Češka republika

Češka republika

359 km

Planetarni brusilnik in polirnik cevi

NS MaquinasML 100 3Z

Klic

Stanje: zelo dobro (rabljeno), Leto izdelave: 2017, Funkcionalnost: popolnoma funkcionalen, Opis stroja: Visoko zmogljiv planetarni brusilnik, zasnovan za končno obdelavo površin (brušenje, satiniranje in poliranje) okroglih in ovalnih profilov. Model ML 100 3Z je opremljen s tremi neodvisnimi brusnimi enotami, ki omogočajo doseganje želene hrapavosti površine v enem samem prehodu.

Glavne prednosti:

Planetarni sistem: Brusni trakovi rotirajo okoli cevi, medtem ko se sam material ne vrti. To omogoča varno obdelavo izjemno dolgih ali rahlo ukrivljenih cevi.

Visoka učinkovitost (3Z): Zaradi treh postaj lahko kombinirate različne granulacije (npr. od grobega brušenja do finega sijaja) brez potrebe po menjavi trakov med operacijami.

Gedpfsx Ti I Djx Afqjtt

Vsestranost: Idealno za nerjaveče jeklo, aluminij, medenino in druge kovine do premera cca 114 mm.

Kakovost površine: Zagotavlja popolnoma enakomerno obdelavo po celotnem obodu brez vidnih spojev.

Stroj je v dobrem tehničnem stanju. Po dogovoru je možen preizkus.

Brusilnik je idealen za obdelavo ravnih okroglih ali ovalnih cevi. Ima orbitalni sistem, ki omogoča večnamensko uporabo. Podajanje obdelovancev in odpiranje trakov je avtomatsko.

Velikost obdelovanca: premer 10–114 mm.

Minimalna dolžina obdelovanca pri avtomatskem podajalnem sistemu: 355 mm.

Število brusnih trakov: 6

Skupna moč: 14 kW.

Hitrost brusnih trakov: 10–30 m/s.

Mali oglas

Grafing

Grafing

313 km

Ploščati dostavnik

Mercedes-BenzVito 116 CDI Kühlkasten 7Gtr SHz Klima FahrStand

Klic

Stanje: rabljeno, prevoženi kilometri: 52.500 km, moč: 120 kW (163,15 KM), prva registracija: 06/2020, vrsta goriva: dizel, skupna masa: 2.800 kg, gorivo: dizel, Izpusti CO₂: 178 g/km, poraba goriva (mestna vožnja): 8 l/100 km, poraba goriva (izven mesta): 6 l/100 km, poraba goriva (kombinirana): 6,8 l/100 km, barva: srebrn, vrsta prenosa: samodejen, emisijski razred: Euro 6, vzmetenje: jeklo, število sedežev: 3, Oprema: ABS, airbag, drsna vrata, filter saj, greljenje sedeža, klimatska naprava, nadzor oprijema, računalnik na krovu, servovolan, sistem za imobilizacijo, tempomat, E07 Hill Start Assist, EY5 Mercedes-Benz Emergency Call System, EY6 Breakdown Management, G42 7G-TRONIC PLUS, F66 lockable glove compartment, H20 all-round heat-insulating glazing, CM2 bumpers and attachments painted in body color, JW8 ATTENTION ASSIST, JK3 instrument cluster with pixel-matrix display, RS3 steel wheels 6.5 J x 16, Y44 warning triangle, LC4 comfort roof control unit, RG1 tires 205/65 R16, ER0 radio pre-installation, XO9 Mercedes-Benz MobiloVan with DSB and GgD, JX2 maintenance interval 40,000 km, SA6 passenger airbag, CF0 standard chassis, MR6 Emission Class Euro 6c N1, JH3 communication module (LTE) for digital services, X30 registration certificate Part II, HH9 semi-automatic TEMPMATIC air conditioning, Y10 first aid kit, MJ8 ECO start-stop function, IB6 model series C447 Vito/V-Class, KB5 main tank 70 liters, RH6 tire brand Hankook, SB1 comfort driver seat, FY7 multi-button remote control, M60 alternator 14 V / 250 A, E28 additional battery for retrofit consumers, MS1 cruise control, VY2 Tunja fabric black, HI1 climate zone 1 (cold/comfort), S23 passenger double seat, XU1 signage / printed materials in German, IG5 Basic, Z41 registration as truck, IG4 Standard, W65 tailgate, LE1 adaptive brake light, ZM0 panel van, RM7 summer tires, D50 full-length partition wall, MG9 generator management, MX0 BlueEFFICIENCY package, E34 buffer battery for starting process, CL1 steering wheel adjustable in tilt and height, E36 separating relay for additional battery, CL4 multifunction steering wheel with trip computer, XZ0 model generation 0, EL8|.

Gsdswy Ac Uepfx Afqett

We would be happy to provide you with a personalized financing or leasing offer and take your used vehicle in payment. We look forward to welcoming you to our dealership for further consultation. Vehicle condition according to age/mileage, partial repainting was carried out during reconditioning. No liability for printing or typographical errors. Subject to changes and prior sale ... more on our homepage.

Mali oglas

Schwanberg

Schwanberg

69 km

Vijačni kompresor

AGRE ALUPSonetto 7,5+ 10

Klic

Stanje: novo, Screw Compressor

AGRE

Model Sonetteo 7.5+ 10

Compact screw compressor system including refrigerated dryer and 270 L receiver tank. Belt-driven. Space-saving. Cost-effective. Simple operation thanks to Infologic² Basic control. Efficient compression stage. The perfect solution for industrial and craft businesses. Outstanding compressed air quality. Integrated refrigerated dryer.

Detailed equipment:

Compression concept: Oil-lubricated screw compressor

Gtodpfehun Tzjx Afqot

Cooling: Air-cooled, efficient cooling system

Drive: Efficient IE3 motor, belt drive

Control: Fixed speed

Controller: Infologic² Basic control unit

Refrigerated dryer: Integrated, refrigerant R513A

Receiver tank: 270 L horizontal, painted, 11 bar

Motor power: 5.5 kW

Pressure: 10 bar

Delivery rate: 780 L/min

Including timed condensate drain

Dimensions (L x W x H): 1500 x 1350 x 600 mm

Mali oglas

Waiblingen

Waiblingen

519 km

Center stružnica

WEILERPraktikant GSD

Klic

Stanje: novo, Leto izdelave: 2025, Praktikant GSD

One of the best-selling and most popular conventional precision lathes

stands out due to:

advanced engineering

highest precision

durability

ergonomics proven in daily practice

minimal space requirements

and a wide range of accessories.

Proven for decades in single-part and small-batch production, across trade and industry, for training and further education, and in tool and fixture construction.

Centre distance: 650 mm

Centre height: 160 mm

Automatic handwheel disengagement

Leadscrew and feed shaft cover

Main spindle brake

Toolroom accuracy according to DIN 8605

Pole-changeable brake motor

Headstock gearbox

16 fixed spindle speed steps

Digital position readout (optional)

LED machine light

TECHNICAL DATA:

WORKING AREA

Centre height 160 mm

Swing over bed 320 mm

Swing over cross slide 190 mm

Centre distance 650 mm

SPINDLE

Spindle nose DIN 55027/DIN ISO 702-3 Size 5

Spindle bore 43 mm

Spindle diameter at front bearing 70 mm

MAIN DRIVE

Drive power 60%/100% duty cycle 2.6 / 3.1 kW

Speed range 48 – 2,500 rpm

Number of speeds 16

FEED RANGE

Number 24

Longitudinal 0.02 – 0.63 mm/rev

Cross 0.006 – 0.2 mm/rev

Godpfx Aowhzcpefqjtt

THREAD CUTTING RANGE

Metric threads 0.25 – 8* mm

TAILSTOCK

Quill diameter 40 mm

Quill stroke 85 mm

Internal taper DIN 228 MK 3

TEST ACCURACY DIN 8605

* Whitworth threads and metric thread pitches 0.45; 0.75; 4.5 and 5.5 are only possible using additional change gears.

The machine is located at our showroom in 71334 Waiblingen-Beinstein and is available immediately. For details on equipment and configuration, please contact us.

Mali oglas

Hallstadt

Hallstadt

520 km

CNC stružnica

OptimumS400HSC CNC

Klic

Stanje: kot nova (razstavni stroj), Leto izdelave: 2024, The machine is located in the showroom and has only been used for demonstration purposes. Optiturn S400 HSC CNC Premium CNC lathe direct from the manufacturer.

S400 HSC – The OPTIMUM premium CNC turning machine with Siemens SINUMERIK 828D control system stands out for its performance, speed, precision, and long service life.

Heavy-duty construction

· Compact design

· SIEMENS servo motors on all axes

· Renishaw measuring arm for tool measurement

· All servo motors with integrated encoder for maximum accuracy

· Main spindle implemented as motor spindle

· 45° slant bed for particularly large machining diameters and unobstructed chip discharge into the chip tray

· Hydraulic three-jaw chuck Ø 170 mm with soft jaws

· Servo tool changer VDI 30 with 12 tool stations

· Hardened and precision-ground ball screws for high rapid traverse speeds on all axes

· Faster tool change speed

· High hydraulic clamping force

· Heavy-duty machining without vibration, for automated machining and high efficiency even under extreme conditions

· Rigid linear guides ensure long service life with maximum static and dynamic stiffness

· Device for manual tool measurement

· Heat exchanger

· Portable electronic handwheel with enabling button and emergency stop switch makes program setup significantly easier

· Belt-type chip conveyor for efficient removal of chips

· Work light for complete illumination of the working area

· Coolant system with cleaning gun

· RJ45 and power interface

· EMC (electromagnetic compatibility)

· Additional SIEMENS material defect liability and free online/on-site service OSS Plus; see "SIEMENS OSS Plus Package" on page 117

· 1 year basic maintenance contract included

Machine specifications

Electrical connection: 400 V / 3 Ph ~50 Hz

Total connected load: 25 kVA

Spindle

Drive motor S1 operation: 11.6 kW

Torque drive motor S1 operation: 65 Nm

Drive motor S6-30% operation: 14.4 kW

Torque drive motor S6-30% operation: 81 Nm

Spindle mount: A2-5

Spindle bore: Ø 56 mm

Chuck passage: Ø 45 mm

Hydraulic chuck: Ø 170 mm

Coolant system

Coolant pump output: 700 W

Tank capacity: 160 liters

Hydraulic system

Hydraulic pump output: 1.5 kW

Tank capacity: 36 liters

Machine data

Max. turning diameter: 220 mm

Turning length: 320 mm

Swing diameter over cross slide: 300 mm

Swing diameter over bed: 500 mm

Slant bed: 45°

Speed range

Spindle speeds*: 30 - 6,000 min⁻¹

Tool changer

Type: Servo VDI 30

Number of tool stations: 12

Accuracy

Repeat accuracy: ±0.004 mm

Positioning accuracy: ±0.004 mm

Travel

Gtodpfx Afow Ebn Heqot

X-axis: 180 mm

Z-axis: 350 mm

Feed force, dynamic

X-axis: 3.6 kN

Z-axis: 3.6 kN

Feed rate

X-axis / Z-axis: 30 m/min

Motor torque

X-axis / Z-axis: 6 Nm

Dimensions

Length x width x height: 2,000 x 2,250 x 1,550 mm

Total weight: 2,600 kg

Mali oglas

Ubstadt-Weiher

Ubstadt-Weiher

585 km

Stroj za vrtanje in rezkanje

FEHLMANNPicomax 51 CNC

Klic

Stanje: zelo dobro (rabljeno), Leto izdelave: 1995, Funkcionalnost: popolnoma funkcionalen, High-precision drilling and milling machine

Fehlmann Model Picomax 51 CNC Heidenhain TNC 360, very good condition, CE compliant

Hthrgw39X

Technical data:

>> Year of manufacture: 1995

>> Travel X/Y/Z: 420 / 240 / 120 mm

>> W-axis travel: 450 mm

>> Clamping surface (L x W): 730 x 280 mm

>> Maximum table load: 75 kg

Gsdpfx Ajuxprlefqjtt

>> Distance table – spindle nose: 0 – 560 mm

>> Feed rate X/Y: 1 – 7200 mm/min

>> Feed rate Z: 1 – 3600 mm/min

>> Tool quick-change system SF 32

>> Stepless speed range up to 9,200 rpm

>> Drive power: 4 kW

>> Space requirement approx. (W x D x H): 2.0 x 1.5 x 2.4 m

>> Fourth axis dividing head

About the machine:

For sale is a high-precision drilling and milling machine, Fehlmann model Picomax 51 CNC, in very good condition and CE compliant. It is equipped with a Heidenhain TNC 360 path control system. Programming is especially easy thanks to the user-friendly Heidenhain plain text dialog. HEIDENHAIN TNCs are workshop-oriented path controls that allow you to program milling and drilling operations directly on the machine in an intuitive plain text dialog. Tool holders (see photos) are included. Mechanically and electrically tested. Take advantage of the opportunity to view and test this machine under power on site.

Mali oglas

Conegliano

Conegliano

210 km

Elektronsko zaustavljanje

SALVAMACCOMBO SALVASTOP 100

Klic

Stanje: novo, Leto izdelave: 2025, Zero errors, no waste, and increased productivity!

We developed SalvaStop_100 as a core component to give your work a competitive edge.

This electronic stop, controlled by a numerical system, precisely manages the feeding, stopping, and positioning of the profiles to be cut—regardless of the material. This allows you to significantly reduce human errors, minimize material waste, and lower labor costs.

SalvaStop_100 comes equipped with exclusive software, featuring an intuitive, instantly accessible graphical interface for easy operation.

Gsdpfx Afjkzhb Ueqott

You can use SalvaStop either as a standalone device or in combination with one of our Legend crosscut saws to boost performance, ensure total operational safety, and virtually eliminate human error.

Mali oglas

Konstanz

Konstanz

475 km

3D tiskalnik

StratasysF170

Stanje: generalkompletno obnovljen (rabljeno), Funkcionalnost: popolnoma funkcionalen, številka stroja/vozila: D01427, Leto izdelave: 2017, obratovalne ure: 7.300 h, We present the Stratasys F170™, a powerful 3D printer that prioritizes reliability and user-friendliness. Equipped with state-of-the-art FDM® technology and seamless integration with the design-to-print platform GrabCAD, the F170 streamlines the 3D printing process for both experienced professionals and newcomers alike.

The F170 offers convenient plug-and-play functionality, enabling you to start printing immediately without complex setup procedures. Automatic calibration ensures precise print results and saves valuable time. Changing print materials is quick and easy, providing flexibility in selecting the right materials for your projects.

With a spacious build volume of 254 x 254 x 254 mm, the F170 allows for printing a wide variety of parts in different sizes. Adjustable layer thicknesses—0.127, 0.178, 0.254, and 0.330 mm—give you the flexibility to tailor print quality to your needs, from fine detail to faster build times.

Gedjrrf Tdjpfx Afqott

The F170 stands out for its reliable and precise printing performance, ensuring consistent results. Thanks to its quiet operation and low emissions, it is ideally suited for use in offices or educational environments.

The Stratasys F170 comes with advanced GrabCAD software, ensuring seamless transfer of your 3D models and easy project management. A comprehensive selection of accessories and consumables is also available to meet your printing requirements.

Expand your 3D printing capabilities with the Stratasys F170 and explore limitless creative possibilities with this dependable and user-friendly 3D printer. Boost your productivity and bring your design visions to life with ease and precision. The Stratasys F170—your reliable partner for professional 3D printing.

This printer is part of the Certified Pre-Owned (CPO) program

Certified Pre-Owned 3D printers are used systems that have been refurbished and serviced by our experts, then verified through a 24-hour test print.

Maintenance Contracts and Additional Services

We provide optimal support before, during, and after your purchase. In addition to services such as on-site installation and team training, we also supply accessories, spare parts, and materials. Enter into a maintenance contract with us to benefit from full planning and cost security, rapid response times, and minimized machine downtime. This ensures you take no risks with your purchase.

If you are still unsure which 3D printing system is right for you, we are happy to advise and answer any questions you may have regarding 3D printing. Request your tailored quote today.

Mali oglas

Schwanberg

Schwanberg

69 km

Drsna namizna žaga

SCMnova si x

Klic

Stanje: novo, Saw unit swivels 46° to both sides. Programmable, electric saw blade adjustment.

Control unit with electronic display for saw blade tilt and height.

Gray cast iron saw unit ensures torsional rigidity and vibration-free operation.

Easy panel handling thanks to large squaring frame with roller.

Telescopic fence with 2 professional flip stops.

Outstanding cutting precision – sliding table guided by a highly precise, time-proven ball contact system for smooth operation.

Scoring unit features its own drive and is easily adjustable from outside.

Saw unit accommodates saw blades up to 400 mm diameter.

Scoring blade diameter: 160 mm.

Two-position manually adjustable saw blade pendulum guard.

3-axis control.

Motorized parallel fence with electronic position control.

Includes:

- Position display via encoder

Gedpfx Asd Akygsfqott

- Adjustment via ball screw spindle

- Stepless setting via switch or automatic positioning system

- Incremental adjustment capability

- Swiveling fence retraction below table

- Cutting width 1270 mm

- Programmed movement of motorized saw unit adjustment and tilting

UP version:

- Swiveling operator panel for maximum flexibility

X version:

- Compex miter fence for fast, precise miter cuts with automatic length compensation (length adjustment)

- Outrigger with angle-adjustable telescopic crosscut fence

- Optional degree scale division (Art.-No.: 5510403)

- Longitudinal fence with 2 LCD position displays

Options included:

- Version with max. sliding table travel of 3200 mm

- Integrated main and scoring blade start/stop switches on the squaring frame

- Squaring frame with CompeX feature

- Version “READY 3 UP”

- 2 cutting speeds (3500/5000 rpm)

Extraction port diameter: 120 & 80 mm

Main motor: 7.0 kW, 400 V, 50 Hz

Squaring frame length: 1200 mm

Squaring frame width: 650 mm

Sliding table length: 3200 mm

Sliding table width: 360 mm

Cutting width with parallel fence: 1270 mm

Max. crosscut width left of blade: 3260 mm

Saw blade tilt: -46 to +46°

Max. cutting height 90°: 136 mm

Max. cutting height 45°: 97 mm

Max. cutting height -45°: 60 mm

Main saw blade diameter: 400 mm

Scoring saw blade diameter: 160 mm

Mali oglas

Hallstadt

Hallstadt

520 km

Rezkalni stroj

OptimumF150E

Klic

Stanje: kot nova (razstavni stroj), Leto izdelave: 2024, The machine is currently on display and has only been used for demonstration purposes. Optimill F 150 E CNC milling machine, directly from the manufacturer.

F 150 E – The OPTIMUM CNC milling machine equipped with Siemens SINUMERIK 808D Advanced control stands out for its performance, speed, precision, and long service life.

- Carousel tool changer with 16 tool positions

- All linear guides with stainless steel covers

- Central automatic lubrication system

- Siemens main spindle motor

- SIEMENS servo drives on all axes (closed loop)

- Belt-type chip conveyor ensures efficient chip removal

- Chip trolley

- Maximum spindle speed: 10,000 rpm

- Work area machine light

- Portable electronic handwheel with enabling switch and emergency stop switch—significantly simplifies program setup

- Coolant system with 190-liter coolant tank

- Tool change is automatic or triggered at the push of a button

- Heavy, precisely machined and large-scale milling table

- Large access doors designed to minimize cleaning and maintenance time

- “SINUMERIK 808D on PC” software package included. (Practical training software allowing for offline programming and simulation of workpieces on PC. The software can be downloaded free of charge.)

SINUMERIK 808 ADVANCED – CNC technology from the market leader, combined with a revolutionary operating concept

The SINUMERIK 808D ADVANCED control is a panel-based CNC control system. This compact and user-friendly entry-level solution is designed for simple milling applications. Features such as intuitive operation, commissioning, and easy maintenance make it the ideal basis for equipping CNC machines.

Through its technology-specific configuration, the SINUMERIK 808D ADVANCED is perfectly preconfigured for milling. Thanks to hardware and software extensions, it provides sufficient performance for basic milling functions in mold and tool making.

Compact and robust

Thanks to its panel-based CNC design with minimal interfaces and an IP65-rated control panel, the SINUMERIK 808D ADVANCED is perfectly suited for use in harsh environments. Its compact dimensions enable installation in smaller machines.

INCLUDED:

- RJ45 Ethernet port

- 8.4” LCD color display with 800 x 600 resolution

- Prepared for remote maintenance

- AST function: allows for easy optimization in tasks requiring greater dynamics and accuracy

- Absolute encoder / No reference run required

- Higher precision

Travel distances:

X = 750 mm

Y = 500 mm

Z = 500 mm

Dimensions and weights:

Length approx. 3,420 mm

Width/Depth approx. 2,050 mm

Height approx. 2,400 mm

Weight approx. 4,500 kg

Drilling/Milling performance:

Maximum face mill diameter: 80 mm

Maximum shank cutter diameter: 38 mm

Gtedpfx Afew Ea Dgsqst

Electrical data:

Supply voltage: 400 V

Mains frequency: 50 Hz

Total connected load: 15 kW

Horizontal milling table:

Length: 900 mm

Width: 500 mm

Vertical spindle – table distance min.: 100 mm

Vertical spindle – table distance max.: 600 mm

T-slot width: 18 mm

Number of T-slots: 5

T-slot spacing: 80 mm

Maximum table load: 350 kg

Accuracy:

Repeatability: ±0.005 mm

Positioning accuracy: ±0.01 mm

Mali oglas

Konstanz

Konstanz

475 km

3D tiskalnik

StratasysEDEN260V

Stanje: generalkompletno obnovljen (rabljeno), številka stroja/vozila: 32405, Leto izdelave: 2012, obratovalne ure: 2.087 h,

Mali oglas

Schwanberg

Schwanberg

69 km

Vretena stroj za brizganje plastike, vretena moulde

SCM MiniMaxTI 105 Nova

Klic

Stanje: novo, Tilting Spindle Moulder

Simple and practical operations thanks to the ergonomic arrangement of the controls on the front of the machine.

Digital display for the height and swivel position of the spindle.

Spindle speed display.

Right/left rotation of the spindle.

8 speeds.

Spindle diameter: 30 mm.

Spindle clamping length: 125 mm.

Max. tool diameter under table: 240 x 80 mm.

Extraction port diameter: 2 x 120 mm.

INCLUDES OPTIONS:

57.02.63 “LL” version for profiling work with 2 table extensions.

57.03.30 Motorized height and angle adjustment of the working unit with digital displays.

57.01.56 Three-phase motor 7.0 kW 50Hz with star-delta switching.

57.00.76 Fence adjustment with handwheel:

- Fence with stepless adjustment via conveniently accessible handwheels on the front:

– Adjustment of the entire fence in relation to the tool.

– Adjustment of the front ruler to change chip removal.

– Mechanical digital displays.

– Wooden pressure faces and connecting rails.

Dimensions (L x W x H): 2500 x 855 x 900 mm

Weight: approx. 550 kg

Note on used machines:

Gtodpfxscuwpte Afqst

• Technical data subject to errors and prior sale reserved.

• Stated prices are ex location and ex loading!

• The machines have been cleaned and tested for function.

• All machines are sold as seen, without any warranty claims.

Buyers are welcome to inspect the machines at the location.

• Special agreements are only valid in written form.

(Inquiries will only be answered if you provide your address and telephone number!)

Mali oglas

Hallstadt

Hallstadt

520 km

Stroj za površinsko brušenje

OptimumGT22 Flächenschleifmaschine

Klic

Stanje: kot nova (razstavni stroj), Leto izdelave: 2024, High-quality spindle with precision tapered roller bearings

Hardened and ground table guideways

Turcite-B coated counter-guides for high wear resistance and low friction

Integrated grinding wheel dressing device

Machine base made of robust, torsion-resistant cast iron for maximum rigidity and stability

Backlash-free V-flat guide on the Z-axis and flat guides on the X and Y-axes

Trapezoidal leadscrew on the Y-axis

Manual central lubrication

All flat guides are finely scraped, ensuring high precision for all manual movements

LED work lamp

Safety electrical system with 24 V DC voltage

Grinding accuracy: 0.005 mm

Corundum grinding wheel, grit 46, for all common steels included as standard

Dual-channel safety electric system

Electromagnetic compatibility (EMC) filter grade

Significant energy savings due to IE3 motor

Coolant unit with external coolant tank

Dimensions and Weights

Length approx. 1970 mm

Width/Depth approx. 1300 mm

Gtodpsw Eay Iofx Afqet

Height approx. 1700 mm

Weight approx. 850 kg

Electrical Data

Drive motor power: 1.5 kW

Connection voltage: 400 V

Mains frequency: 50 Hz

Surface Grinding Table

Clamping surface length: 200 mm

Clamping surface width: 500 mm

Grinding Wheel(s)

Outside diameter: 200 mm

Width: 20 mm

Bore: 31.75 mm

Peripheral speed: 33 m/s

Spindle

Speed: 2850 rpm

Run-out accuracy: 0.005 mm

X-Axis

Feed rate: Manual

Mali oglas

Schwanberg

Schwanberg

69 km

Kombinirani planer

SCM MiniMaxfs 41 es

Klic

Stanje: novo, Digital version with motorized thickness table adjustment

• Helical-toothed steel feed roller for constant and uniform material feed

• Material feed with two speeds

• Extra-long surfacing tables enable easy and precise planing of workpieces

• Work tables are made of stress-relieved, annealed cast iron—durable, distortion-free, and highly resistant

• Surfacing tables open to the rear simultaneously for minimal setup times

• The high machine weight ensures maximum precision and smooth operation

• Powerful industrial motor

• Robust steel/cast iron construction

• Chip removal from as little as 0.2 mm (with a minimum workpiece thickness of 3 mm) thanks to the helical-toothed feed roller—ideal for efficient planing of precious timber

Technical Data:

Working width 410 mm

Cutterhead diameter (mm) 95 mm

Max. chip removal 5 mm

Total surfacing table length 2200 mm

Thickness table dimensions 410 x 775 mm

Thickness table feed speed 6/12 m/min

Min./max. working height thickness table 3 – 240 mm

Min. working length thickness 180 mm

Motor power 5.0 kW, 400V, 50 Hz

Gtjdpfx Afsdvn Hweqot

Including the following options:

• Motorized thickness table adjustment with digital display

• Fold-down auxiliary fence for thin workpieces

• TERSA cutterhead system

Mali oglas

Hallstadt

Hallstadt

520 km

Stružnica - ciklično krmiljena

OptimumL44 CNC

Klic

Stanje: kot nova (razstavni stroj), Leto izdelave: 2025, The machine is currently in the showroom and has only been used for demonstration purposes. Optiturn L44 CNC Premium CNC lathe, directly from the manufacturer.

L44 CNC – The OPTIMUM Premium CNC lathe with Siemens SINUMERIK 828D control stands out for its performance, speed, precision, and long service life.

Dimensions and Weights

Max. width/depth: 2300 mm

Length approx.: 2530 mm

Width/depth approx.: 1595 mm

Height approx.: 1795 mm

Weight approx.: 2600 kg

Working Areas

Chuck diameter: 150 mm

Chuck clamping control: Hydraulic

Centre height: 223 mm

Distance between centres: 850 mm

Swing over bed: 446 mm

Swing over gap: 520 mm

Swing over cross slide: 240 mm

Bed width: 300 mm

Motor Torque

X axis: 6 Nm

Z axis: 8.5 Nm

Speed Range

Number of speed ranges: 1

Speed range: 10 – 3000 rpm

Electrical Data

Drive motor power: 7 kW

Connection voltage: 400 V

Mains frequency: 50 Hz

Electrical Connection

Total connected load: 23 kVA

Accuracy

Repeatability: ± 0.005 mm

Positioning accuracy: ± 0.005 mm

Hydraulic System

Motor power: 0.75 kW

Tank capacity: 50 l

Coolant System

Coolant pump power: 270 W

Tank capacity: 90 l

Machine Data

Chuck passage diameter: 40 mm

Motor(s)

Drive motor torque: 33 Nm

Tailstock

Quill taper: MK 4

Quill stroke: 165 mm

Quill diameter: 52 mm

Spindle

Spindle mount: DIN ISO 702-1 No. 5

Spindle bore/bar capacity: 52 mm

Control

Type: Sinumerik 828D PPU 240

System software: SW 24

CNC memory: 3 MB

Look Ahead: 50

Block change time: 3 ms

Number of tools: 128

Travel

X axis: 250 mm

Z axis: 760 mm

Vertical Spindle

Continuous duty drive motor power (S1): 7 kW

Drive motor power S6-30% duty: 16 kW

Drive motor torque: 33 Nm

Drive motor S6-30% duty: 80 Nm

Feed Rate

X axis: 15,000 mm/min

Z axis: 15,000 mm/min

Feed Force

Feed force X axis: 7.5 kN

Feed force Z axis: 5.3 kN

Tool Changer

Type: Hydraulic; VDI 30

Number of tool stations: 8

Max. tool shank height/width (square): 20 x 20 mm

Max. boring bar diameter: 25 mm

SIEMENS SAFETY INTEGRATED

Features

Main Spindle

- Heavy-duty design

Machine Bed

- Deeply ribbed

- High rigidity and durability

Guides

- Robust flat bed guideways

Ball Screw

- For high rapid traverse speeds in all axes

- Reduced wear

- High positioning and repeatability accuracy

Cast Iron Body

- Hardened to HRC48-52 and heat-treated

Machine Feet

- Six pieces

Gtjdjw Ea Tuepfx Afqet

- Optimal machine alignment

Heat Exchanger

- Enclosed control cabinet with intelligent cooling management

- Optimal temperature even at high ambient temperatures

Tool Changer System

- Eight tool stations

- Hydraulic VDI30 tool changer

- Max. tool shank height: 20 mm

Hydraulic Unit

- Motor power: 750 W

- Tank capacity: 50 litres

- Clamping/operating pressure: 2,500 – 2,942 kPa

Three-Jaw Chuck

- Hydraulic three-jaw chuck Ø 150 mm

- Hydraulic unclamping and clamping via foot pedal

- Easy clamping of workpieces

- Hard and soft top jaws

Central Lubrication System

- Automatic interval lubrication

- Reduces wear on bearings, guides, and ball screws

- With float switch: an audible signal sounds if the oil level is too low

Mali oglas

Sankt Peter im Sulmtal

Sankt Peter im Sulmtal

70 km

Stroj za linijsko vrtanje

MAGGI / SCMBORING SYSTEM 21 PRESTIGE

Klic

Stanje: kot nova (razstavni stroj), pneumatic single-head boring machine with 21 spindles

MAGGI

Gsdpfod Supgox Afqjtt

Model: Boring System 21

STANDARD EQUIPMENT:

- Aluminium fence with 2 stops (each 1,500 mm, right and left)

- No. 5 quick-change chucks

- No. 2 patented safety pneumatic hold-down cylinders

- Connector for suction/extraction unit compliant with EU standards

KEY FEATURES:

- Worktable made of cast iron

- Boring head made of aluminium

- Patented spiral system for fine adjustment of drilling depth

- Pneumatic lowering of the boring head, lockable in any position between 0° - 90°

- Extendable cast iron side stops with millimetre adjustment, readable on a scale with magnifier

- Drill height adjustment via digital counter with decimal display

- Fixed stops, 37 mm, for cup hinges

- Machine constructed according to CE standards

TECHNICAL DATA:

- Boring spindles (left red/right black): 21 pcs. (10/11)

- Distance between boring spindles: 32 mm

- Working width: 640 mm

- Max. drilling depth: 65 mm

- Number of pneumatic hold-down cylinders: 2 pcs.

- Max. workpiece size: 900 x 3000 x 60 mm

- Max. workpiece height: 65 mm

- Number of motors: 1 pc.

- Motor power: 1.5 kW, 400 V, 50 Hz

- Motor speed: 2800 rpm

- Working pressure: 6-8 bar

- Standard air consumption per cycle: 10 l/cycle

- Extraction port diameter: 80 mm

- Worktable height: 860 mm

Overall dimensions (approx.) L x W x H: 1030 x 1030 x 1285 mm

Weight (approx.): 260 kg

Mali oglas

Hallstadt

Hallstadt

520 km

Rezkalni stroj

OptimumF80 CNC

Klic

Stanje: kot nova (razstavni stroj), Leto izdelave: 2025, The machine is currently on display and has only been used for demonstration purposes. Optimill F 80 CNC milling machine, direct from the manufacturer.

• Column-type machine bed made of cast iron for high rigidity

• Carousel-type tool changer with 12 tool positions

• All linear guides equipped with stainless steel covers

• Automatic central lubrication system

• Siemens main spindle motor

• Siemens servo drives on all axes (closed control loop)

• Maximum spindle speed of 10,000 rpm

• The portable electronic handwheel with enabling button and emergency-stop switch greatly simplifies program setup

SINUMERIK 808 ADVANCED

CNC technology from the industry leader

SINUMERIK 808D on PC

• Identical control software package, further simplifying machine operation

Compact and Robust

• Thanks to its panel-based CNC design with few interfaces and a control panel rated to IP65, the SINUMERIK 808D ADVANCED is perfectly suited for operation in demanding environments

Communication Interfaces

• Front-panel USB (IP65)

• Serial interface RS232C

• Rear RJ45 Ethernet port

• Technology-specific keyboard layout

• Durable hard keys with protective membrane

Dimensions and Weight

Length: approx. 1995 mm

Width/Depth: approx. 1930 mm

Height: approx. 1640 mm

Weight: approx. 2300 kg

Rapid Traverse Speed

X-axis: 20 m/min

Y-axis: 20 m/min

Z-axis: 20 m/min

Electrical Data

Connection voltage: 400 V

Mains frequency: 50 Hz

Electrical connection

Total connected load: 12 kVA

Horizontal milling table

Length: 800 mm

Width: 260 mm

Distance vertical spindle – table (min.): 100 mm

Distance vertical spindle – table (max.): 550 mm

T-slot size: 16 mm

Number of T-slots: 5

Distance between T-slots: 50 mm

Maximum load: 200 kg

Precision

Repeatability: ± 0.01 mm

Positioning accuracy: ± 0.01 mm

Coolant System

Coolant pump drive power: 450 W

Tank capacity: 80 l

Pneumatic Connection

Operating pressure: 7 bar

Travel

X-axis (automatic): 450 mm

Y-axis (automatic): 260 mm

Z-axis (automatic): 450 mm

Distance spindle to column (max.): 370 mm

Vertical Spindle

Spindle taper: BT 40

Speed range: 50 – 10,000 rpm

Cont. drive motor power S1: 3.7 kW

Drive motor power S6-30%: 5.5 kW

Gjdjw Ea Rtepfx Afqott

Cont. drive motor torque S1: 24 Nm

Drive motor torque S6-30%: 36 Nm

Feed Motor Torque

X-axis (S1): 6 Nm

Y-axis (S1): 6 Nm

Z-axis (S1): 11 Nm

Tool Changer

Type: Carousel

Number of tool stations: 12 tools

Maximum tool diameter: 95 mm

Maximum tool length: 300 mm

Maximum tool weight: 8 kg

Tool change time (chip-to-chip): 7 s

Znak zaupanja

Prodajalci, certificirani pri Machineseeker

Mali oglas

Hallstadt

Hallstadt

520 km

Radialni vrtalni stroj

OptimumRadialbohrmaschine RD6

Klic

Stanje: kot nova (razstavni stroj), Leto izdelave: 2024, Optimum OPTIdrill RD 6

Highly precise, heavy-duty radial drilling machines of top quality. Ideal for flexible use in both single-part and series production.

• Versatile applications including drilling, reaming, and tapping

• Electrically braked motor

• 24V DC electrics and dual-channel safety circuit in accordance with DIN EN 12717

• Heavy-duty, high-grade cast-iron construction

• Wide outreach thanks to horizontally adjustable machine head

• Clearly arranged control panel

• Smooth-running swivel and travel axes

• Elaborately engineered column swivel with optimized clamping for maximum stability and minimal alignment deviation

• Rigid, torsion-resistant boom construction

• Boom height adjustment via powerful motor drive and lift spindle

• Drill head gearbox operates in oil bath

• Hardened and precision-ground boom guideways

• Hardened and precision-ground chrome-nickel steel gear wheels for smooth and quiet gearbox operation

• Drill head and column can be clamped or released together or separately

• Forward/reverse operation

• Large, solid, and precise drill table

• Hardened and ground clamping table with parallel T-slots

• Integrated machine lamp

• Overload protection

• Thick-walled cast column ensures high running smoothness and stability

• LED lamp

• Coolant system with integrated tank in machine base

RD 6 / RD 7

• Column is clamped hydraulically

Dimensions and Weights:

Column diameter: 320 mm

Length approx.: 2670 mm

Width/depth approx.: 1120 mm

Height approx.: 2760 mm

Weight approx.: 3200 kg

Boom Arm:

Swivel angle: 180°

Drilling Capacity:

Drilling capacity in steel (S235JR): 50 mm

Continuous drilling capacity in steel (S235JR): 45 mm

Drill Table:

T-slot size: 14 mm

T-slot quantity: 4

T-slot spacing: 180 mm

Max. spindle-to-table distance: 1420 mm

Clamping table length: 630 mm

Clamping table width: 500 mm

Clamping table height: 500 mm

Clamping table T-slot size: 22 mm

Clamping table T-slot quantity: 3

Clamping table T-slot spacing: 150 mm

Min. spindle-to-clamping table distance: 0 mm

Max. spindle-to-clamping table distance: 910 mm

Min. spindle-to-table distance: 465 mm

Speed Range:

Spindle speed range: 44 – 1023 rpm

Number of speed ranges: 12

Electrical Data:

Total connected load: 6.5 kW

Connection voltage: 400 V

Mains frequency: 50 Hz

Machine Base:

Working surface length: 2550 mm

Working surface width: 970 mm

Motors:

Spindle drive motor power: 4 kW

Boom height adjustment motor power: 1.5 kW

Coolant pump drive motor power: 90 W

Hydraulic clamping drive power: 0.75 kW

Spindle:

Quill stroke: 270 mm

Spindle taper: MK5

Quill feed rate: 0.06 – 0.2 mm/rev

Quill feed rate steps: 3

Travel:

Gtsdpfx Aswa Tc Sjfqst

Drill head (horizontal travel): 1250 mm

Boom lift (vertical travel): 680 mm

Max. spindle-to-column distance: 1600 mm

Min. spindle-to-column distance: 350 mm

Mali oglas

Hallstadt

Hallstadt

520 km

Rezkalni stroj

OptimumF3 Pro CNC

Klic

Stanje: kot nova (razstavni stroj), Leto izdelave: 2025, The machine is on display and has only been used for demonstration purposes. Optimill F 3 Pro CNC milling machine (training machine) directly from the manufacturer.

F 3 PRO – The OPTIMUM CNC milling machine with Siemens SINUMERIK 808D Advanced control system stands out for its performance, speed, precision, and long service life.

- All linear guides with stainless steel covers

- Automatic central lubrication

- SIEMENS servo drive on all axes (open-loop control)

- Max. spindle speed: 4000 rpm

- Work area machine light

- Portable electronic handwheel with enabling switch and emergency-stop slam switch. Greatly simplifies program setup

- Tool changes by push button

- Large access doors to minimize cleaning and maintenance time

- Software package 'SINUMERIK 808D on PC' included (practical training software for offline programming and simulation of workpieces on PC; available for free download)

SINUMERIK 808D ADVANCED – CNC technology from the technology leader, paired with a revolutionary operating concept

The SINUMERIK 808D ADVANCED control is a panel-based CNC system. The compact and user-friendly entry-level solution is used for basic milling applications. Features such as simple operation, commissioning, and maintenance make it the perfect foundation for equipping CNC machines.

Compact and robust

Thanks to a panel-based CNC design with few interfaces and a control panel with IP65 protection class, the SINUMERIK 808D ADVANCED is ideally prepared for operation in harsh environments. Its compact dimensions make it suitable for installation in smaller machines.

Gsdpew Ea R Hofx Afqett

INCLUDED

- RJ45 Ethernet port

- 8.4" LCD color display with 800 x 600 resolution

- Remote maintenance ready

Dimensions & Weights

- Length: approx. 1410 mm

- Width/depth: approx. 1372 mm

- Height: approx. 2007 mm

- Weight: approx. 1000 kg

Drilling/Milling capacity

- Max. cutter head size: 50 mm

- Max. shank cutter size: 25 mm

Electrical Data

- Connection voltage: 400 V

- Network frequency: 50 Hz

- Electrical connection

- Total connected load: 5 kVA

Horizontal Milling Table

- Length: 620 mm

- Width: 180 mm

- Distance vertical spindle – milling table min.: 50 mm

- Distance vertical spindle – milling table max.: 295 mm

- T-slot size: 12 mm

- Number of T-slots: 3

- T-slot spacing: 50 mm

- Maximum load capacity: 30 kg

Accuracy

- Repeatability: ± 0.02 mm

- Positioning accuracy: ± 0.01 mm

Coolant/Lubricant System

- Coolant pump drive power: 95 W

- Tank capacity: 30 l

Travel

- X-axis (auto): 355 mm

- Y-axis (auto): 190 mm

- Z-axis (auto): 245 mm

Vertical Spindle

- Spindle taper: BT 30

- Speed range: 4000 rpm

- Note: max. spindle speed must be reduced by approx. 20% during continuous operation

- Drive motor power S1 (continuous): 1.5 kW

- Drive motor power S6-30% (intermittent): 2.2 kW

- Drive motor torque S1 (continuous): 9.5 Nm

- Drive motor torque S6-30%: 14 Nm

Feed Rate

- X-axis: 10,000 mm/min

- Y-axis: 10,000 mm/min

- Z-axis: 10,000 mm/min

Feed Motor Torque

- X-axis S1 (continuous): 1.9 Nm

- Y-axis S1 (continuous): 3.5 Nm

- Z-axis S1 (continuous): 3.5 Nm

Mali oglas

Hallstadt

Hallstadt

520 km

CNC stružnica

OptimumL28 HS CNC

Klic

Stanje: kot nova (razstavni stroj), Leto izdelave: 2025, Machine is on display. Optiturn L28 HS CNC lathe - directly from the manufacturer.

L28 HS - The OPTIMUM CNC lathe equipped with Siemens SINUMERIK 808D Advanced PPU 150 control.

- Reinforced machine bed made of cast iron

- High-quality spindle bearing

- Emergency stop push-switch

- Centralized lubrication system

- Reference switches

- Maintenance-friendly protective enclosure

- Rear maintenance access panel

- Safety switch on the front sliding door

- Turret positioned behind the turning center (left-hand turning tools)

- Linear guides

- Software package “SINUMERIK 808D on PC” included (practical training software allowing workpieces to be programmed and simulated offline on a PC; free to download)

- Includes two-year SIEMENS warranty

Gtedpfxow Ebnge Afqot

Technical Data

Electrical connection: 400 V / 3 Ph ~50 Hz

Total connected load: 3.75 kVA

Spindle

- Drive motor (S1 operation): 2.2 kW

- Torque drive motor (S1 operation): 14 Nm

- Torque at spindle: 28 Nm

- Spindle mount: DIN 6350 A2-3

- Spindle taper: 5C

- Spindle bore: Ø 30 mm

Coolant System

- Coolant pump power: 95 W

- Tank capacity: 25 liters

Machine Data

- Center height: 169 mm

- Center distance: 430 mm

- Swing over cross slide: Ø 200 mm

- Swing over bed: Ø 300 mm

Speed Range

- Spindle speeds*: 40 - 4,000 rpm

Tool Turret

- Type: Electric

- Number of tool stations: 6 tools

- Maximum tool shank size (square): 16 mm

- Maximum boring bar diameter: 16 mm

Precision

- Repeatability: ± 0.01 mm

- Positioning accuracy: ± 0.01 mm

Travel

- X-axis: 145 mm

- Z-axis: 465 mm

Feed Rate

- X-axis: 10,000 mm/min

- Z-axis: 12,000 mm/min

Machine leasing available via Siemens Finance (subject to liquidity).

Mali oglas

Hallstadt

Hallstadt

520 km

UMENJA

OptimumTX5216V Vario

Klic

Stanje: rabljeno, Leto izdelave: 2023, Optimum Optiturn TX 5216V – Used Machine.

Machine bed made from heavily ribbed cast iron

One-piece machine base made from steel

High rigidity of the headstock housing thanks to heavily ribbed 25GG cast iron

Precisely machined carriage

Shafts mounted on needle bearings, all components lubricated in an oil bath

Bed guideways hardened and precision ground

All electronic controls centrally accessible

All feed gearbox gears made of hardened steel

Handwheels decoupled and inspected according to EN 23125

Dual-channel safety electronics

Switches with life-cycle calculation, tested to EN ISO 13849

Full leadscrew and feed screw cover

Fully illuminated work area

Service-friendly removable rear panel

Hardened and ground face plate spindle ensures exceptional accuracy and durability

Gjdpfx Aex Hdq Tjfqett

High material removal rate in rough machining thanks to large cutting capacity

Energy chain for gentle cable and hose guidance

Lockable chip guard travels with the carriage, featuring integrated position indicator and coolant hose, manually adjustable

No change gears required

Equipped with safety device against simultaneous operation of threading and feed mechanisms

Electronic feed stop for the Z-axis

Coolant system with separate coolant tank featuring fill level indicator and oil separator; easy and complete emptying and cleaning as per DIN

Electrical position shutoff with quadruple position stop

Three-jaw chuck included as standard

Quick-change tool post SWH 7-C

Tool holder 32 x 130 type D for 25 mm square tools

Large spindle bore

Dimensions and Weights

Length approx. 2925 mm

Width/Depth approx. 1195 mm

Height approx. 1930 mm

Weight approx. 2470 kg

Work Area

Centre height: 260 mm

Centre distance: 1600 mm

Swing over bed: 520 mm

Swing over cross slide: 324 mm

Bed width: 350 mm

Speed Range

Number of speed ranges: 2 x 3 steps

Speed range: 12 – 1800 rpm

Electrical Data

Output (motor power): 7.5 kW

Total connected load: 5.5 kW

Connection voltage: 400 V

Network frequency: 50 Hz

Coolant System

Coolant pump power: 60 W

Type of generated data: Usage data

Tailstock

Quill taper: MK 5

Quill travel: 180 mm

Quill diameter: 72 mm

Spindle

Spindle mounting: Camlock DIN ISO 702-2 No. 8

Spindle bore/bar pass-through diameter: 80 mm

Tool post: SWH 7C

Spindle taper: MK 7

Thread Cutting

Metric pitch: 0.5 – 15 mm/rev

Number of metric pitches: 55

Imperial pitch: 60 – 2 TPI

Number of imperial pitches: 55

Diametral pitch: 120 – 4 DP

Number of diametral pitches: 55

Module thread pitch: 0.25 – 7.5 mm x π

Number of module pitches: 55

Travel

Cross slide travel: 170 mm

Compound rest travel: 340 mm

Carriage travel: 1400 mm

Feed

Longitudinal feed range: 0.05 – 1.5 mm/rev

Number of longitudinal feeds: 55

Flat feed range: 0.025 – 0.75 mm/rev

Number of flat feeds: 55

Olajšamo vam iskanje: "hank"

Nove ponudbe prejmete takoj in brezplačno po e-pošti.

Iskalno nalogo lahko kadar koli preprosto končate.

Rabljeni Hank (4.440)

Zdaj preiščite celoten Machineseeker z več kot 200.000 rabljenimi stroji.Brskajte po najbolj priljubljenih poimenovanjih strojev:

Izvedite več zdaj

+44 20 806 810 84

+44 20 806 810 84

Objavite oglas zdaj

*na oglas/mesec