Stroj za vrtanje lukenj za moznikeGanner

DB 21

Stroj za vrtanje lukenj za moznike

Ganner

DB 21

Leto izdelave

2024

Stanje

Rabljeno

Lokacija

Nattheim

Prikaži slike

Prikaži karto

Podatki o stroju

- Opis stroja:

- Stroj za vrtanje lukenj za moznike

- Proizvajalec:

- Ganner

- Model:

- DB 21

- Leto izdelave:

- 2024

- Stanje:

- rabljeno

Cena in lokacija

- Lokacija:

- Daimlerstr. 21, 89564 Nattheim, DE

Klic

Podrobnosti ponudbe

- ID ponudbe:

- A20292745

- Št. reference:

- BD-P-24005

- Nazadnje posodobljeno:

- dne 22.01.2026

Opis

Dowel Hole Boring Machine GANNOMAT "DB 21400V, 3Ph, 50Hz / 1.5 kW complete in standard configuration including:

- Fully automatic electronic control with pulse operation via foot pedal for clamping-drilling-unclamping, with electric skip function.

- Automatic return of the drilling unit after reaching the set drilling depth.

- Automatic extension of borehole depth when drilling on the end-face. This eliminates the need to reset borehole depth when switching from wide-face to end-face drilling (+10 mm, for example, with dowel length 35 mm, drilling depth wide-face 14 mm, and drilling depth end-face 24 mm).

- 1 drilling beam with 21 spindles, 32 mm pitch, 1.5 kW motor (drilling feed 0-70 mm), including 21 quick-change chucks (Ganner system) for easy drill bit changes.

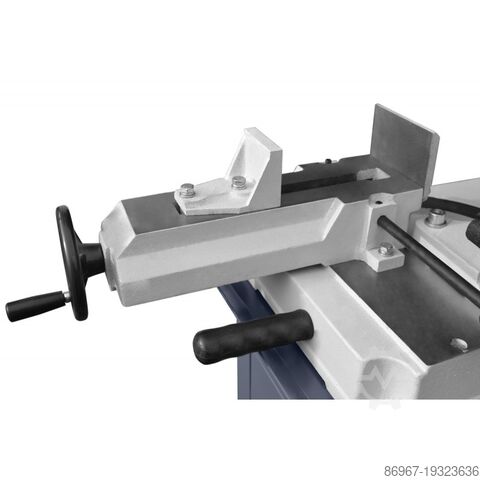

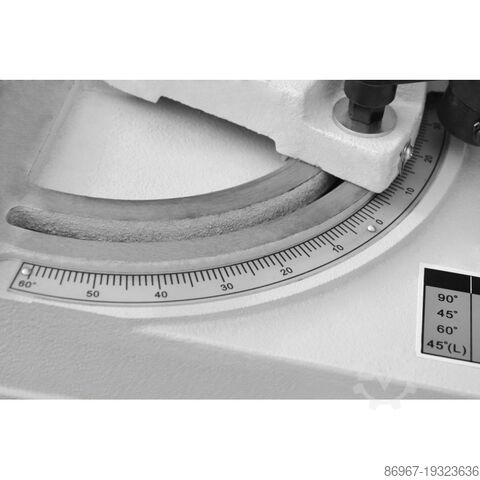

- Simple pivoting of the drilling unit from 0° to 90°, assisted by gas cylinder.

- 1 clamping rail adjustable on the Y-axis with 3 pneumatic clamping cylinders, for workpiece height up to max. 80 mm.

Ideal positioning system consisting of:

- 1 stop ruler 1800 mm for drilling shelves and intermediate panels, (aluminium profile 40x40 mm) with 3 drop-in stops.

- With quick-change system, easily swapped from right to left stop side for mirror-image drilling of shelves and intermediate panels in carcass constructions. Also suitable for line boring in 32 mm system.

- Side stops and position adjustments, as well as drilling height adjustment via mechanical digital counters on the support table.

- Side stops can be easily pivoted away for quick changeover from carcass to frame and line drilling operations.

- Clamping arms for clamping rail designed for line boring positions up to max. 300 mm.

Ksdsxnlflopfx Af Noll

- Ideal three-stage tooling system.

- 1 set of dowel drills: 5 HM dowel drill bits, Ø 8x77 mm, right-hand - 4 HM dowel drill bits, Ø 8x77 mm, left-hand

Basic machine Dowel Hole Boring Machine GANNOMAT "DB 21400V, 3Ph, 50Hz / 1.5 kW complete in standard configuration including:

- Fully automatic electronic control with pulse operation via foot pedal for clamping-drilling-unclamping, and electric skip function.

- Automatic return of the drilling unit after reaching the set drilling depth.

- Automatic extension of the borehole depth for end-face drilling, eliminating the need to adjust the drilling depth from wide-face to end-face (+10 mm, e.g. with dowel length 35 mm, wide-face drilling depth 14 mm, end-face drilling depth 24 mm).

- 1 drilling beam with 21 spindles, 32 mm pitch, 1.5 kW motor (drilling feed 0-70 mm), including 21 quick-change chucks (Ganner system) for easy drill bit changes.

- Simple pivoting of the drilling unit from 0° to 90°, assisted by gas cylinder.

- 1 clamping rail adjustable on the Y-axis with 3 pneumatic clamping cylinders, for workpiece height up to max. 80 mm.

- Ideal positioning system consisting of:

- 1 stop ruler 1800 mm for drilling shelves/intermediate panels (aluminium profile 40x40 mm) with 3 drop-in stops,

- quick-change system, easily switched from right to left stop side for mirror-image shelf drilling in carcass construction; also suitable for line boring in System 32.

- Side stops and position adjustments, as well as drilling height adjustment via mechanical digital counters on the support table.

- Side stops can be easily pivoted away for ultra-fast changeover from carcass to frame and line boring.

- Clamping arms for clamping rail suited for line boring positions up to max. 300 mm.

- Ideal three-stage tooling system.

Extraction funnel, dust-teste

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

- Fully automatic electronic control with pulse operation via foot pedal for clamping-drilling-unclamping, with electric skip function.

- Automatic return of the drilling unit after reaching the set drilling depth.

- Automatic extension of borehole depth when drilling on the end-face. This eliminates the need to reset borehole depth when switching from wide-face to end-face drilling (+10 mm, for example, with dowel length 35 mm, drilling depth wide-face 14 mm, and drilling depth end-face 24 mm).

- 1 drilling beam with 21 spindles, 32 mm pitch, 1.5 kW motor (drilling feed 0-70 mm), including 21 quick-change chucks (Ganner system) for easy drill bit changes.

- Simple pivoting of the drilling unit from 0° to 90°, assisted by gas cylinder.

- 1 clamping rail adjustable on the Y-axis with 3 pneumatic clamping cylinders, for workpiece height up to max. 80 mm.

Ideal positioning system consisting of:

- 1 stop ruler 1800 mm for drilling shelves and intermediate panels, (aluminium profile 40x40 mm) with 3 drop-in stops.

- With quick-change system, easily swapped from right to left stop side for mirror-image drilling of shelves and intermediate panels in carcass constructions. Also suitable for line boring in 32 mm system.

- Side stops and position adjustments, as well as drilling height adjustment via mechanical digital counters on the support table.

- Side stops can be easily pivoted away for quick changeover from carcass to frame and line drilling operations.

- Clamping arms for clamping rail designed for line boring positions up to max. 300 mm.

Ksdsxnlflopfx Af Noll

- Ideal three-stage tooling system.

- 1 set of dowel drills: 5 HM dowel drill bits, Ø 8x77 mm, right-hand - 4 HM dowel drill bits, Ø 8x77 mm, left-hand

Basic machine Dowel Hole Boring Machine GANNOMAT "DB 21400V, 3Ph, 50Hz / 1.5 kW complete in standard configuration including:

- Fully automatic electronic control with pulse operation via foot pedal for clamping-drilling-unclamping, and electric skip function.

- Automatic return of the drilling unit after reaching the set drilling depth.

- Automatic extension of the borehole depth for end-face drilling, eliminating the need to adjust the drilling depth from wide-face to end-face (+10 mm, e.g. with dowel length 35 mm, wide-face drilling depth 14 mm, end-face drilling depth 24 mm).

- 1 drilling beam with 21 spindles, 32 mm pitch, 1.5 kW motor (drilling feed 0-70 mm), including 21 quick-change chucks (Ganner system) for easy drill bit changes.

- Simple pivoting of the drilling unit from 0° to 90°, assisted by gas cylinder.

- 1 clamping rail adjustable on the Y-axis with 3 pneumatic clamping cylinders, for workpiece height up to max. 80 mm.

- Ideal positioning system consisting of:

- 1 stop ruler 1800 mm for drilling shelves/intermediate panels (aluminium profile 40x40 mm) with 3 drop-in stops,

- quick-change system, easily switched from right to left stop side for mirror-image shelf drilling in carcass construction; also suitable for line boring in System 32.

- Side stops and position adjustments, as well as drilling height adjustment via mechanical digital counters on the support table.

- Side stops can be easily pivoted away for ultra-fast changeover from carcass to frame and line boring.

- Clamping arms for clamping rail suited for line boring positions up to max. 300 mm.

- Ideal three-stage tooling system.

Extraction funnel, dust-teste

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Ponudnik

Opomba: Brezplačno se registrirajte ali prijavite, za dostop do vseh informacij.

Registriran od: 2010

Pošlji zahtevo

Telefon & Faks

+49 7321 ... oglasi

Ti oglasi bi vas prav tako lahko zanimali.

Mali oglas

Siedlce

Siedlce

853 km

Tračna žaga

CORMAKBS-128HDRC 400V

CORMAKBS-128HDRC 400V

Mali oglas

Siedlce

Siedlce

853 km

Skobeljni stroj - debelinka

CORMAKPT250 230V

CORMAKPT250 230V

Mali oglas

Bad Sooden-Allendorf

Bad Sooden-Allendorf

677 km

Stroj za izdelavo čepov

ScheerDB 150

ScheerDB 150

Mali oglas

Juszczyn

Juszczyn

530 km

Vrtalni stroj z več vreteni

MaggiBoring System 35

MaggiBoring System 35

Mali oglas

Nordhorn

Nordhorn

903 km

Iverna plošča Talna obloga Skladiščna ploščad ploščad

4.000 m², 3.200 mm x 1.000 mm x 38 mmAusführung: P6

4.000 m², 3.200 mm x 1.000 mm x 38 mmAusführung: P6

Mali oglas

Certaldo

Certaldo

425 km

Večvretenski vrtalni stroj

Maggi EngineeringBoring System 800 GT

Maggi EngineeringBoring System 800 GT

Mali oglas

Berlin

Berlin

718 km

Popolna zaščita in večja varnost.

Bodori5 3000W

Bodori5 3000W

Mali oglas

Wijchen

Wijchen

922 km

Briketirni stroj Schuko Compacto CT 700 S-20 2017

SchukoCompacto CT 700 S-20

SchukoCompacto CT 700 S-20

Mali oglas

Siedlce

Siedlce

853 km

Brusilnik robov

CORMAKMM2315Q 400/230V

CORMAKMM2315Q 400/230V

Mali oglas

Karsin

Karsin

887 km

Večvretenska vrtalna naprava Vitap Alfa 21

Vitapalfa 21r

Vitapalfa 21r

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake