Navpični obdelovalni centerBrema

Vektor 15 - 13

Navpični obdelovalni center

Brema

Vektor 15 - 13

Leto izdelave

2019

Stanje

Rabljeno

Lokacija

Sesto Calende

Prikaži slike

Prikaži karto

Podatki o stroju

- Opis stroja:

- Navpični obdelovalni center

- Proizvajalec:

- Brema

- Model:

- Vektor 15 - 13

- Leto izdelave:

- 2019

- Stanje:

- rabljeno

Cena in lokacija

- Lokacija:

- Sesto Calende, Italy

Klic

Podrobnosti ponudbe

- ID ponudbe:

- A10298021

- Št. reference:

- MHF003

- Nazadnje posodobljeno:

- dne 18.10.2024

Opis

Highly flexible vertical machining center for milling, drilling, and cutting. The BREMA patent for processing.

Due to its vertical orientation, this machine series is the most flexible and productive machine of its kind, achieving an extremely high quality standard. In addition, the automatic return/rotation system for the panels ensures fully automatic operation.

It is possible to work on all 6 sides of the panel at a height of up to 1300 mm.

Working dimensions:

* Length: 300 - 2500 mm

* Height: 60 - 1300 mm

* Thickness: 10 - 80 mm

* Maximum weight: 50 kg

Machine programming and control system operated via PC - TPA Albatros software.

The programming editor, featuring a high-level software interface, allows for simple, intuitive machine programming and also offers:

* Linear, circular, and spiral interpolation

* Double zero point

* Mirror program management

* Turret tool diameter optimizer

* Independent spindle diameter optimizer

Lrsdpjl Ikzgsfx Abbjg

* DXF file conversion (geometric conversion)

* Import of worklists in ASCII format

* Additional key for office-based programming

* Barcode scanner

* 17-inch LCD monitor

* Professional operating system Windows 7

Panel feeding and handling via motorized vertical transfer with rollers and rubber-coated pressure units for securing the panel during processing. Includes a motorized conveyor carpet length of 2000 mm, with electronically adjustable speed via converter. Photo sensors and NC program ensure sequential feeding of one or multiple panels as selected by the operator.

Height reading system for panels consisting of an independent axis capable of reading the panel height before loading into the machine.

Reading tolerance for dimension: +/- 0.15 mm. If the tolerance is exceeded, a message is displayed and the operator and machine stop the active operation.

Panel thickness reading system using a mechanical probe.

Horizontal vice – M.O. axis: allows the program to determine the workpiece thickness.

Vertical vice – M.V. axis: allows the program to determine the workpiece height dimension.

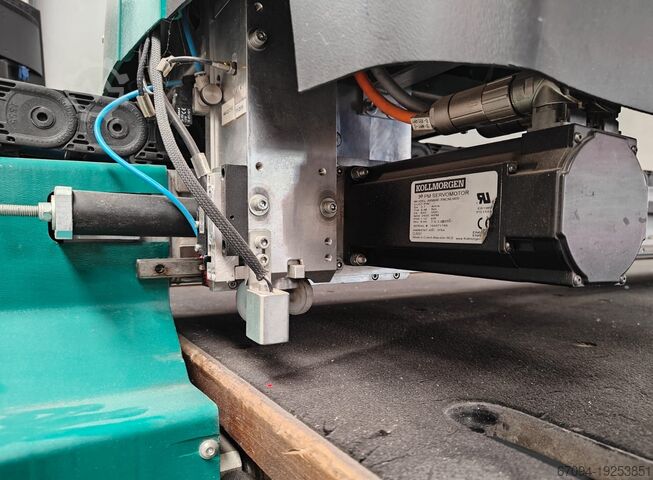

Chain - X axis: Patented double section with laser photo sensors capable of reading the reference zero point prior to machining operations. The double section allows machining on the underside of the panel, permitting processing of all 6 panel sides. Brushless motors with programmable speed control via NC.

Drilling unit with independent spindles 7 + 17 x 32 mm

24 independent spindles with 32 mm pitch, arranged as follows:

* 7 spindles oriented on X axis

* 17 spindles oriented on Y axis

Powered by a high-frequency motor, which enables spindle rotation changes up to 7,000 rpm. The brushless motor allows control of drilling depth and feed speed.

Upper turret milling group with 10 positions and NC-controlled tool change. 11 kW motor with direct motion transfer to the tool up to 18,000 rpm. The turret rotates via a controlled axis with a brushless motor, enabling...

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Due to its vertical orientation, this machine series is the most flexible and productive machine of its kind, achieving an extremely high quality standard. In addition, the automatic return/rotation system for the panels ensures fully automatic operation.

It is possible to work on all 6 sides of the panel at a height of up to 1300 mm.

Working dimensions:

* Length: 300 - 2500 mm

* Height: 60 - 1300 mm

* Thickness: 10 - 80 mm

* Maximum weight: 50 kg

Machine programming and control system operated via PC - TPA Albatros software.

The programming editor, featuring a high-level software interface, allows for simple, intuitive machine programming and also offers:

* Linear, circular, and spiral interpolation

* Double zero point

* Mirror program management

* Turret tool diameter optimizer

* Independent spindle diameter optimizer

Lrsdpjl Ikzgsfx Abbjg

* DXF file conversion (geometric conversion)

* Import of worklists in ASCII format

* Additional key for office-based programming

* Barcode scanner

* 17-inch LCD monitor

* Professional operating system Windows 7

Panel feeding and handling via motorized vertical transfer with rollers and rubber-coated pressure units for securing the panel during processing. Includes a motorized conveyor carpet length of 2000 mm, with electronically adjustable speed via converter. Photo sensors and NC program ensure sequential feeding of one or multiple panels as selected by the operator.

Height reading system for panels consisting of an independent axis capable of reading the panel height before loading into the machine.

Reading tolerance for dimension: +/- 0.15 mm. If the tolerance is exceeded, a message is displayed and the operator and machine stop the active operation.

Panel thickness reading system using a mechanical probe.

Horizontal vice – M.O. axis: allows the program to determine the workpiece thickness.

Vertical vice – M.V. axis: allows the program to determine the workpiece height dimension.

Chain - X axis: Patented double section with laser photo sensors capable of reading the reference zero point prior to machining operations. The double section allows machining on the underside of the panel, permitting processing of all 6 panel sides. Brushless motors with programmable speed control via NC.

Drilling unit with independent spindles 7 + 17 x 32 mm

24 independent spindles with 32 mm pitch, arranged as follows:

* 7 spindles oriented on X axis

* 17 spindles oriented on Y axis

Powered by a high-frequency motor, which enables spindle rotation changes up to 7,000 rpm. The brushless motor allows control of drilling depth and feed speed.

Upper turret milling group with 10 positions and NC-controlled tool change. 11 kW motor with direct motion transfer to the tool up to 18,000 rpm. The turret rotates via a controlled axis with a brushless motor, enabling...

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Ponudnik

Opomba: Brezplačno se registrirajte ali prijavite, za dostop do vseh informacij.

Registriran od: 2017

Pošlji zahtevo

Telefon & Faks

+39 0331 ... oglasi

Ti oglasi bi vas prav tako lahko zanimali.

Mali oglas

Lennestadt

Lennestadt

753 km

Obdelovalni center s prehodnim podajanjem

BRE.MAVEKTOR 15-13 CNC

BRE.MAVEKTOR 15-13 CNC

Mali oglas

Maasmechelen

Maasmechelen

870 km

Miza za rezanje stekla

Bottero548LAM-38 2.0 - 363BCS-J 2.0

Bottero548LAM-38 2.0 - 363BCS-J 2.0

Mali oglas

Hedel

Hedel

945 km

Tovornjak z žerjavom

ScaniaR560 V8 2012 HMF 30TM!!CRANE/KRAN/GRUE!! 6x2!FU...

ScaniaR560 V8 2012 HMF 30TM!!CRANE/KRAN/GRUE!! 6x2!FU...

Mali oglas

Barbing

Barbing

380 km

Dvostranski stroj za brušenje stekla

Schiatti AngeloBFP12

Schiatti AngeloBFP12

Mali oglas

Zevenbergen

Zevenbergen

974 km

CNC stružnica z Y-osjo, gnana. WK

Mori SeikiNL 2500 SY / 1250

Mori SeikiNL 2500 SY / 1250

Mali oglas

Gondelsheim

Gondelsheim

575 km

Mostni žerjav Dvoranski žerjav Žerjavna steza Žerjav

Stahl 250KG Hängekran 1,5-6,35 mKranhimmel Portalkran Kran mehrere vorh.

Stahl 250KG Hängekran 1,5-6,35 mKranhimmel Portalkran Kran mehrere vorh.

Mali oglas

Gościcino

Gościcino

967 km

Miza za rezanje stekla

GlastonUC 1000

GlastonUC 1000

Mali oglas

Krefeld

Krefeld

843 km

Teleskopski transportni transportni trak tračni transporter

BuddeTGF03

BuddeTGF03

Mali oglas

Maasmechelen

Maasmechelen

870 km

Miza za rezanje stekla

Bottero353BKM-J

Bottero353BKM-J

Mali oglas

Sliven

Sliven

979 km

Optimizacija križnih črt

WEINIGOpticut 200 Elite

WEINIGOpticut 200 Elite

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake