Kombinacija obračalnih miz za gradnjo lesenih okvirjevRandek AB

BS20

Kombinacija obračalnih miz za gradnjo lesenih okvirjev

Randek AB

BS20

Leto izdelave

2026

Stanje

Novo

Lokacija

Falkenberg

Prikaži slike

Prikaži karto

Cena in lokacija

- Lokacija:

- Falkenberg, Schweden

Klic

Podrobnosti ponudbe

- ID ponudbe:

- A896820

- Št. reference:

- BS20

- Nazadnje posodobljeno:

- dne 22.01.2026

Opis

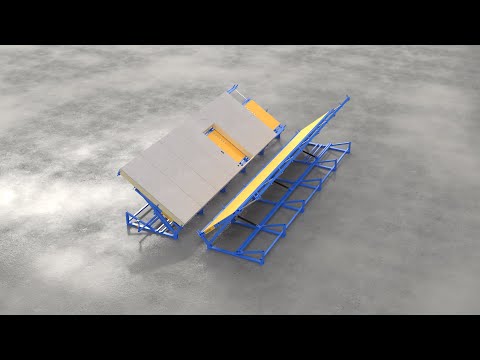

Tilting Table Combination for Timber Frame Construction – BS20

The Randek Tilting Table Combination is an efficient tool for the production of prefabricated walls, roofs, floors, and gable structures with timber or metal frames. The tables can be operated as standalone units or integrated into production lines. Perfectly square building components of high quality are ensured by the clamping function. The lifting and tilting of the components are performed through a controlled, manually operated process. This tilting table combination is designed specifically for the manufacture of prefabricated houses, enabling high productivity.

The adjustable assembly height for building elements ranges from 2.25 m to 3.10 m. The following table lengths are available: 6.0 m / 7.5 m / 9.0 m / 12.0 m. Wall thickness can vary between 80 and 250 mm.

Functions:

The tilting table combination was developed to efficiently perform the following processes: frame assembly, insertion of insulation material, stapling of plastic or paper films, and application and nailing of wall cladding.

• Production of square building components. The pneumatic clamping mechanism along the long side of the master table presses the frame assembly into a square, high-quality, precise building component

• Automatic tilting of the building component, manually controlled

• Automatic raising of the building component

Technical Description:

• Lengths available: 6.0 m / 7.5 m / 9.0 m / 12.0 m

• Adjustable width between 2250 – 3100 mm; width is set manually and easily

• The master table can be hydraulically raised up to 92°, the slave table up to 86°

• Pneumatically activated pressing function on the long side of the master table

• Stops 160 mm high

• Both tables are, as far as technically feasible, covered with plywood. The plywood sheathing allows sub-components and beams to be placed directly on the table

• Tabletops supported by a robust steel frame

• Optimal working height of 620 mm

• Longitudinal C-profiles for positioning stops for studs

• Tables are delivered ready for assembly. Installation is straightforward

Safety:

• Emergency stop switch on control panel

• CE conformity

Advantages:

Nkedpfx Ao Nn Hyog Teu

• Perfectly square building elements through the pressing function

• Controlled automatic raising and tilting of the components

• Ideal working height

• Flexible width adjustment

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

The Randek Tilting Table Combination is an efficient tool for the production of prefabricated walls, roofs, floors, and gable structures with timber or metal frames. The tables can be operated as standalone units or integrated into production lines. Perfectly square building components of high quality are ensured by the clamping function. The lifting and tilting of the components are performed through a controlled, manually operated process. This tilting table combination is designed specifically for the manufacture of prefabricated houses, enabling high productivity.

The adjustable assembly height for building elements ranges from 2.25 m to 3.10 m. The following table lengths are available: 6.0 m / 7.5 m / 9.0 m / 12.0 m. Wall thickness can vary between 80 and 250 mm.

Functions:

The tilting table combination was developed to efficiently perform the following processes: frame assembly, insertion of insulation material, stapling of plastic or paper films, and application and nailing of wall cladding.

• Production of square building components. The pneumatic clamping mechanism along the long side of the master table presses the frame assembly into a square, high-quality, precise building component

• Automatic tilting of the building component, manually controlled

• Automatic raising of the building component

Technical Description:

• Lengths available: 6.0 m / 7.5 m / 9.0 m / 12.0 m

• Adjustable width between 2250 – 3100 mm; width is set manually and easily

• The master table can be hydraulically raised up to 92°, the slave table up to 86°

• Pneumatically activated pressing function on the long side of the master table

• Stops 160 mm high

• Both tables are, as far as technically feasible, covered with plywood. The plywood sheathing allows sub-components and beams to be placed directly on the table

• Tabletops supported by a robust steel frame

• Optimal working height of 620 mm

• Longitudinal C-profiles for positioning stops for studs

• Tables are delivered ready for assembly. Installation is straightforward

Safety:

• Emergency stop switch on control panel

• CE conformity

Advantages:

Nkedpfx Ao Nn Hyog Teu

• Perfectly square building elements through the pressing function

• Controlled automatic raising and tilting of the components

• Ideal working height

• Flexible width adjustment

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Dokumenti

Ponudnik

Opomba: Brezplačno se registrirajte ali prijavite, za dostop do vseh informacij.

Registriran od: 2011

Pošlji zahtevo

Telefon & Faks

+49 5721 ... oglasi

Ti oglasi bi vas prav tako lahko zanimali.

Mali oglas

Engen

Engen

508 km

Popolna žaga (stacionarna)

EWD Spaner SägewerkDWK 700 T-4 340

EWD Spaner SägewerkDWK 700 T-4 340

Mali oglas

Roches-Prémarie-Andillé

Roches-Prémarie-Andillé

1.124 km

Debelača

KUPFERMUHLEDOMA 2050

KUPFERMUHLEDOMA 2050

Mali oglas

Cochem-Brauheck

Cochem-Brauheck

732 km

Krožna žaga za lahke kovine / aluminij

MTIAS-800

MTIAS-800

Mali oglas

San Giovanni Al Natisone

San Giovanni Al Natisone

124 km

KROŽNA ŽAGA ZA KOTIRANJE

SCMSI 450 EP CLASS

SCMSI 450 EP CLASS

Mali oglas

Heiligenhaus

Heiligenhaus

824 km

Industrijski roboti

KUKAKR210 KRC4 3100mm Industrieroboter

KUKAKR210 KRC4 3100mm Industrieroboter

Mali oglas

Roches-Prémarie-Andillé

Roches-Prémarie-Andillé

1.124 km

Nastavljiva krožna žaga s potiskalcem, 6 metrov

STROMABCT 600

STROMABCT 600

Mali oglas

Nersingen

Nersingen

445 km

Mehanizacija za proizvodnjo KVH in BSH

HIT

HIT

Mali oglas

Soest

Soest

784 km

Grafična miza za varjenje

Heinrichsglück - MechaconHorizontaldrehtisch HDT10.000-P1.500

Heinrichsglück - MechaconHorizontaldrehtisch HDT10.000-P1.500

Mali oglas

Mindelheim

Mindelheim

400 km

Pokončna ploščna žaga HOLZ-HER CUT 1255

HOLZ-HERCUT 1255

HOLZ-HERCUT 1255

Mali oglas

Nemčija

Nemčija

650 km

Robot industrijski robot

Kuka KUKAKR180 R3100 K prime KRC4 2015

Kuka KUKAKR180 R3100 K prime KRC4 2015

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake