Rezkalni Stroj nakup rabljenega (27.530)

Wiedergeltingen

Wiedergeltingen 5-osni CNC rezkalni stroj

HG GRIMME SysTech GmbHCNC Maschine - 5-Achs Fräsmaschine RT-F

Wiedergeltingen

Wiedergeltingen 5-osni CNC rezkalni stroj

HG GRIMME SysTech5-Achs CNC Fräsmaschine G-S-F/B

Ospedaletto

Ospedaletto Rezkalni stroj / utorni stroj za prečnike

FomIndustrieMistral 26

+44 20 806 810 84

Wiedergeltingen

Wiedergeltingen 5-osni CNC rezkalni stroj

HG GRIMME SysTech GmbHCNC Maschine - 5-Achs Fräsmaschine RT-F

Wiedergeltingen

Wiedergeltingen 5-osni CNC rezkalni stroj

HG GRIMME SysTech GmbH5-Achs CNC Fräsmaschine G-S-F(35-15)/U

Odkrijte več rabljenih strojev

Aach

Aach Rezkalni stroj

DECKEL MAHODMU 80 P duoBlock

Schwabach

Schwabach Ročno vzvodni rezkalni stroj

RUMAGNachfräsmaschine

Chemnitz

Chemnitz Rezkalni stroj

SCHIELEFUW 525/725 AUERBACH

Lambsborn

Lambsborn Namizni rezkalni stroj

KölleTyp F

Schwanberg

Schwanberg Trdni rezkalni stroj

SCHELLINGFZ 4

Röthenbach an der Pegnitz

Röthenbach an der Pegnitz Univ. orodni rezkalni stroj

Friedrich DeckelDeckel FP1 Fräsmaschine

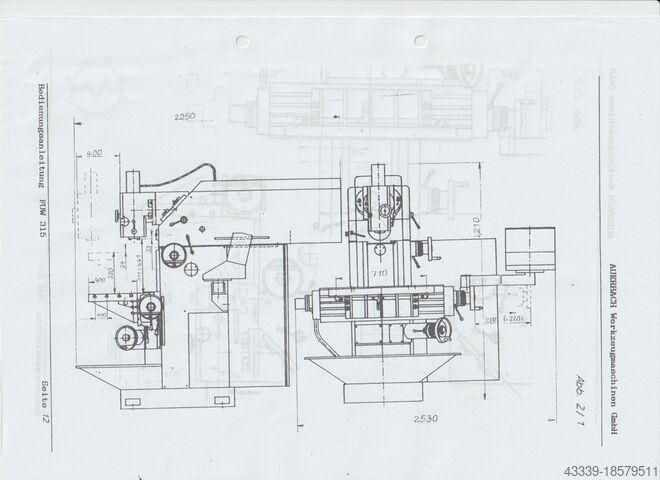

Iserlohn

Iserlohn Rezkalni stroj

AUERBACHFUW 315

Iserlohn

Iserlohn CNC rezkalni stroj

MAHOMH 500 W

Iserlohn

Iserlohn Rezkalni stroj

MAHOMH600-C

Iserlohn

Iserlohn Univerzalni rezkalni stroj CNC

DMG MORIMH 600 C

Iserlohn

Iserlohn Rezkalni stroj

MAHOMH 500 W4

Iserlohn

Iserlohn Rezervni deli CNC univerzalni rezkalni stroj

DECKELFP5NC

Iserlohn

Iserlohn CNC rezkalni stroj

TOSFGS40CNC

Iserlohn

Iserlohn Rezkalni stroj

UNITECHFSS 315 - S7

Iserlohn

Iserlohn Univerzalni rezkalni stroj

KUNZMANNUF 6 / 3

Eslarn

Eslarn Rezkalni stroj

KunzmannWF 600 CNC

Eilenburg

Eilenburg Rezkalni stroj

MIKRONWF 31 DE

Eilenburg

Eilenburg Rezkalni stroj

DECKELFP5NC Dialog 4

Eilenburg

Eilenburg Rezkalni stroj

SHWUF31

Seregno

Seregno Rezkalni stroj za zobnike

LORENZLS 1.000

Rabljeni Rezkalni Stroj (27.530)

Zdaj preiščite celoten Machineseeker z več kot 200.000 rabljenimi stroji.Brskajte po najbolj priljubljenih poimenovanjih strojev:

+44 20 806 810 84