CENTER ZA OBDELAVO PROFILOVELUMATEC

SBZ 122/70 PLUS

CENTER ZA OBDELAVO PROFILOV

ELUMATEC

SBZ 122/70 PLUS

Leto izdelave

2022

Stanje

Rabljeno

Lokacija

Zamość

Prikaži slike

Prikaži karto

Podatki o stroju

- Opis stroja:

- CENTER ZA OBDELAVO PROFILOV

- Proizvajalec:

- ELUMATEC

- Model:

- SBZ 122/70 PLUS

- Serijska številka:

- 12200991016

- Leto izdelave:

- 2022

- Stanje:

- zelo dobro (rabljeno)

- Funkcionalnost:

- popolnoma funkcionalen

Cena in lokacija

- Lokacija:

- ul. Przemysłowa 22, 22-400 Zamość, Polska

Klic

Tehnične podrobnosti

- Vrtljajska hitrost (min.):

- 24.000 obr/min

- Skupna masa:

- 1.635 kg

- Teža orodja:

- 2.900 g

- Vhodna napetost:

- 400 V

Podrobnosti ponudbe

- ID ponudbe:

- A19049101

- Nazadnje posodobljeno:

- dne 30.04.2025

Opis

For economical and efficient machining of aluminium profiles, plastics, and thin-walled steel profiles.

All machining processes such as milling, drilling, and tapping are performed on a stationary profile, protecting the surface of the profile.

Improved performance thanks to the use of intelligent control technology.

Fast positioning of the machining unit at speeds up to 60 m/min with dynamic servo drives.

Tapping without compensating chuck.

Automatic clamp recognition and positioning.

Automatic tool magazine with four tool shelves (tools not included).

Modern 3-axis control system.

Ergonomic operation thanks to a modern slanted bed design.

No need for axis referencing with absolute encoder-based systems.

Collision avoidance through automatic clamp recognition and positioning.

Power-Torque milling spindle with closed-loop speed control ensures short spindle start-up and braking times.

Certified drive-integrated safety functions.

Iasdpfswgmyqox Af Tsl

Low power consumption due to intelligent control technology.

Increased energy efficiency through axis drive interconnection between circuits.

Emergency power supply (UPS).

Windows operating system.

15.6" PC panel, i3 processor, USB ports, and network interface.

Easy and convenient program input with eluCam directly on the operator panel—even during machining.

Online remote maintenance.

Machine Equipment

- Air-cooled milling spindle 8 kW, S1

- Operator protection cabin

- Four horizontal pneumatic clamps for material fixation

- Material stop, left side

- HSK-F63 tool holder

- Minimal quantity lubrication

- High-performance coolant

- Manual control panel

- Depth gauge template

Options

- Tools

- Tool holders

- Automatic tool magazine for up to four standard tools

- Automatic tool magazine for angle head

- Rotating angle head HSK-F63 for two tools

- Green-line cooling unit for control cabinet with reduced energy consumption

- Barcode scanner

- Protective cabin, optionally with full enclosure

- Four clamps as standard; expandable up to eight clamps

- Right reference material stop for processing workpieces with excess lengths

- Additional stop for processing excess lengths on the left side

- Double-sided length measurement

- Dual clamp and additional accessories on request

- 18.5" PC panel, i5 processor

- 21.6" PC panel, i7 processor

- Notepad holder

- Soundproof cover

- Chip disposal using chip trays

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

All machining processes such as milling, drilling, and tapping are performed on a stationary profile, protecting the surface of the profile.

Improved performance thanks to the use of intelligent control technology.

Fast positioning of the machining unit at speeds up to 60 m/min with dynamic servo drives.

Tapping without compensating chuck.

Automatic clamp recognition and positioning.

Automatic tool magazine with four tool shelves (tools not included).

Modern 3-axis control system.

Ergonomic operation thanks to a modern slanted bed design.

No need for axis referencing with absolute encoder-based systems.

Collision avoidance through automatic clamp recognition and positioning.

Power-Torque milling spindle with closed-loop speed control ensures short spindle start-up and braking times.

Certified drive-integrated safety functions.

Iasdpfswgmyqox Af Tsl

Low power consumption due to intelligent control technology.

Increased energy efficiency through axis drive interconnection between circuits.

Emergency power supply (UPS).

Windows operating system.

15.6" PC panel, i3 processor, USB ports, and network interface.

Easy and convenient program input with eluCam directly on the operator panel—even during machining.

Online remote maintenance.

Machine Equipment

- Air-cooled milling spindle 8 kW, S1

- Operator protection cabin

- Four horizontal pneumatic clamps for material fixation

- Material stop, left side

- HSK-F63 tool holder

- Minimal quantity lubrication

- High-performance coolant

- Manual control panel

- Depth gauge template

Options

- Tools

- Tool holders

- Automatic tool magazine for up to four standard tools

- Automatic tool magazine for angle head

- Rotating angle head HSK-F63 for two tools

- Green-line cooling unit for control cabinet with reduced energy consumption

- Barcode scanner

- Protective cabin, optionally with full enclosure

- Four clamps as standard; expandable up to eight clamps

- Right reference material stop for processing workpieces with excess lengths

- Additional stop for processing excess lengths on the left side

- Double-sided length measurement

- Dual clamp and additional accessories on request

- 18.5" PC panel, i5 processor

- 21.6" PC panel, i7 processor

- Notepad holder

- Soundproof cover

- Chip disposal using chip trays

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Ponudnik

Opomba: Brezplačno se registrirajte ali prijavite, za dostop do vseh informacij.

Pošlji zahtevo

Telefon & Faks

+48 602 5... oglasi

Ti oglasi bi vas prav tako lahko zanimali.

Mali oglas

Barakfakih

Barakfakih

1.330 km

Aluminij Pvc ročni režijski stroj za rezanje nad glavo

PLASTMAK PVC ALÜMİNYUM İŞLEME MAKİNALARISÇ 431

PLASTMAK PVC ALÜMİNYUM İŞLEME MAKİNALARISÇ 431

Mali oglas

Birmingham

Birmingham

1.407 km

Časnikarstvo zavora

Baykal320ton x 4metre

Baykal320ton x 4metre

Mali oglas

Buchholz

Buchholz

756 km

Separator oljne megle

ISI Gruppe -RON 60 STR - 350 m³/h – 230 V

ISI Gruppe -RON 60 STR - 350 m³/h – 230 V

Mali oglas

Rödermark

Rödermark

625 km

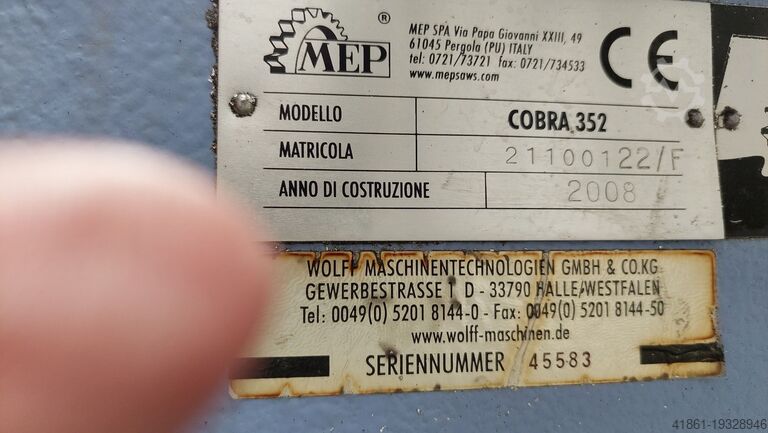

Aluminijasta kotna žaga

MEPCobra 352

MEPCobra 352

Mali oglas

Aalborg

Aalborg

1.261 km

Postaja za montažo krila

FEDERHENNSBZ-100-G

FEDERHENNSBZ-100-G

Mali oglas

Fevziçakmak

Fevziçakmak

1.709 km

Stroj za odstranjevanje napak iz pločevine

TFONSurfacer® TF-RB 2510

TFONSurfacer® TF-RB 2510

Mali oglas

Zamość

Zamość

791 km

Stroj za rezkanje kopij

RotoxZOR 941

RotoxZOR 941

Mali oglas

Kruševac

Kruševac

575 km

Popolnoma avtomatska žaga za optimizacijo 9 m

ProfiFeed TechnologiesA550 Fully Automatic Mitre Aluminium Saw

ProfiFeed TechnologiesA550 Fully Automatic Mitre Aluminium Saw

Mali oglas

Ostrożne

Ostrożne

915 km

En vodja žaganjem stroj

ElumatecMGS

ElumatecMGS

Mali oglas

Wesel

Wesel

866 km

Vibracijski sistem za dodelavo

ERBAEVP-A 550 Rundvibrator mit Separierung

ERBAEVP-A 550 Rundvibrator mit Separierung

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake