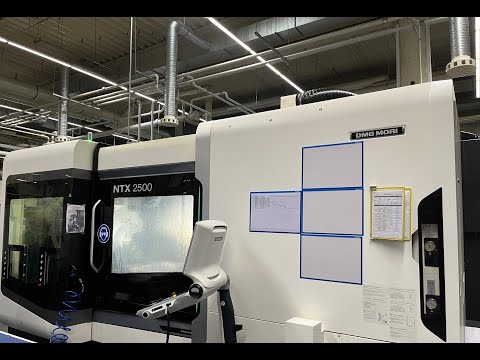

CNC center za struženje in rezkanjeDMG MORI

NTX 2500/1500

Podatki o stroju

- Opis stroja:

- CNC center za struženje in rezkanje

- Proizvajalec:

- DMG MORI

- Model:

- NTX 2500/1500

- Serijska številka:

- NTX26200913

- Leto izdelave:

- 2020

- Stanje:

- pripravljen za uporabo (rabljen)

- Funkcionalnost:

- popolnoma funkcionalen

Tehnične podrobnosti

- Stružna dolžina:

- 1.530 mm

- Premer struženja:

- 670 mm

- Največja hitrost vretena:

- 12.000 obr/min

- Potovalna razdalja osi X:

- 675 mm

- Pomik osi Y:

- 300 mm

- Pomik po osi Z:

- 40 mm

- Največja hitrost vrtenja:

- 4.000 obr/min

- Število mest v zalogovniku orodij:

- 76

zagotovitev

- Lokacija:

- Bayern, Nemčija

– Razdalja: pribl. 491 km

– Razdalja: pribl. 491 km

- Razpoložljivost:

- takoj po zaključku dražbe

- Dobavni pogoji:

- FCA

brezplačno

brezplačno

Opis

Simultaneous 5-axis machining with direct drive (DDM) in the B-axis

HIGHLIGHTS

Milling spindle: compactMASTER with the shortest overall length of 350 mm

Machining option: 6-sided complete machining thanks to a powerful sub-spindle

TECHNICAL DETAILS

X1-axis travel: 675 mm (+550 / -125 mm)

Y1-axis travel: 300 mm (+/-150 mm)

Y2-axis travel: +/-40 mm

Machining area

Maximum machining area: Ø 670 mm x 1,530 mm

Control

Control type: FANUC F31iB5 with CELOS

Operation: CELOS - ERGOline Touch

Spindle

Main spindle: Standard spindle Ø 91 mm, 4,000 rpm

Counter spindle: Standard spindle Ø 91 mm, 4,000 rpm

Chuck

Main spindle chuck: Hollow chuck 10", Ø 254 mm

Counter spindle chuck: KITAGAWA 10" hollow chuck BB210A821

Protection: Double-foot switch with protective cover for main and counter spindles

Stroke control: Automatic stroke control of the chuck cylinder for main and counter spindles

Turn-mill spindle

Spindle (B-axis): Standard speed 12,000 rpm (FANUC)

Tool holder: Capto C6

Positioning: B-axis with 0.0001° accuracy for 5-axis machining

Tool turret

Type: Turret 2 with tailstock function

Equipment: 10-station turret for bolt-mounted tool holders

Milling performance: 6,000 rpm, 40 Nm (Turret 2, FANUC)

Tool magazine

Capacity: 76 tools

Tool holder: CAPTO C6

Measuring and monitoring

Tool presetting: Manual tool presetter for main and counter spindle, removable (standard)

Linear measuring system: Direct measurement system in the X, Y and Z axes of the turn-mill spindle

Sensor system: Spindle sensor measuring system with wireless signal transmission, Renishaw RMP600

Automation

Signal lamp: 4-color (red, yellow, green, blue)

Interface: For bar feeder (LNS, IRCO, IEMCA, Edge Technologies, multiple)

MACHINE DETAILS

Machine dimensions (L x W): 5,825 x 2,830 mm

Cooling media and chip removal

Chip conveyor: Discharge right, hinged belt + drum filter

Coolant: Use of water-soluble coolant (emulsion)

Pressure: High-pressure coolant system with 70 bar

Coolant supply: Through the spindle for tool spindle and lower turret

Filter system: Knoll/Interlit

Compressed air system

Blow-off system: For chucks on main and counter spindles

Oil mist extraction system

Oil mist separator: Suction opening Ø 200 mm, AFS 1600

Filter and cooling system

Filter system: INTERLIT TMF300/980 compact filter unit, 70 bar

Additional pressure: 15 bar for Turret II with lift pump (FANUC/MITSUBISHI)

Chiller: INTERLIT auxiliary chiller, 15 kW

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Obdelava plačil

- Dodatni stroški nakupa:

- 18 %

- Plačilni pogoji:

- 100 % predplačilo

- Načini plačila:

Bančno nakazilo

Podrobnosti ponudbe

- ID ponudbe:

- A18348571

- Št. reference:

- AUC-2410140

- Nazadnje posodobljeno:

- dne 28.01.2025

- Ekskluzivna ponudba:

- na voljo samo na dražbi

ogled

Offenbach an der Queich

Offenbach an der Queich Boehringer-VDF250 CM x 3000 mm

Avstrija

Avstrija DURMAHRB-4 3016

品川区

品川区 OKUMAMULTUS B750 C3000

Monheim am Rhein

Monheim am Rhein DMG MORIDMF 180

Andelst

Andelst GroveRT890 E ROUGH TERRAIN CRANE + JIB+ 2 x WINCH

Borgo San Dalmazzo

Borgo San Dalmazzo MORI SEIKINZ 2000 T2Y2

Nemčija

Nemčija WenzelLH 87 3 D

Großrudestedt

Großrudestedt MAZAKNTX48

Biebrich

Biebrich DMG MoriCLX 350 V 4

Auction Conditions

The contractual language is German. The German version of these Auction Conditions shall prevail. The English version is for information purposes only.

- Auction goods are sold on behalf of and for the account of the seller cooperating with Machineseeker Group GmbH.

- All prices and bids are net prices and do not include VAT.

- Stated dismantling and loading costs are binding.

- All information is provided to the best of knowledge – Machineseeker Group GmbH generally recommends to inspect used machinery.

- Bidding is reserved for commercial buyers – sale exclusively to commercial buyers.

- The duration of an auction may be subject to change.

- By placing a bid, the prospective buyer declares herself/himself to be knowledgeable and informed with regards to auction good(s).

- Submitted direct or maximum bids are binding.

- Machineseeker Group GmbH reserves the right to examine incoming bids. Bids can be rejected or cancelled without providing reasons.

- The winning bid is designated at offer period end, conditional to the minimum price defined by the seller.

- In case of acceptance of a bid, Machineseeker Group GmbH charges closing costs of 18 % net on the buyer’s net bid (unless stated differently in the listing).

- The General Auction Terms of Machineseeker Group GmbH apply.