Tračna žagaCORMAK

HBS275

Tračna žaga

CORMAK

HBS275

Stalna cena brez DDV

1.349 €

Leto izdelave

2025

Stanje

Novo

Lokacija

Siedlce

Prikaži slike

Prikaži karto

Podatki o stroju

Cena in lokacija

Stalna cena brez DDV

1.349 €

- Lokacija:

- Brzeska 120, 08-110 Siedlce, Polska

Klic

Podrobnosti ponudbe

- ID ponudbe:

- A16883691

- Nazadnje posodobljeno:

- dne 07.01.2026

Opis

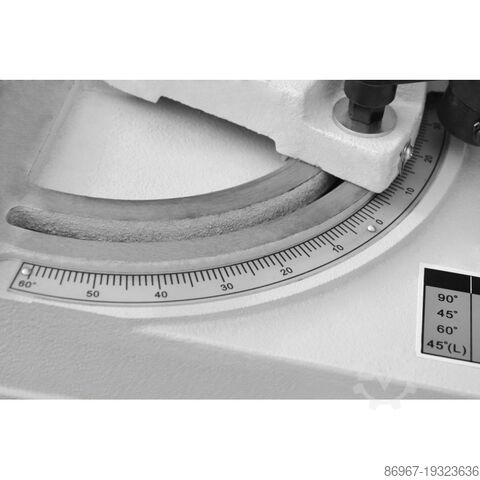

CORMAK HBS275 Bandsaw for cutting pipes, profiles, and bars is widely used in all metalworking shops where precision, quality, and cutting speed matter. This model features a swiveling arm (0-60°), and the blade guides are carbide-based. The frame design ensures accurate and quiet operation.

Machine Features

This horizontal metal bandsaw with a swiveling arm allows cutting at right angles to the material axis as well as at any angle from 0 to 60°. Materials can be fed manually or using any mechanical device, while the tool feed occurs automatically. The blade guides feature special carbide pads and bearings, significantly affecting blade guidance, longevity, straightness, and cutting accuracy and quality. Carbide guidance greatly reduces machine and blade wear. The machine is equipped with a high-efficiency coolant pump in a closed-loop cooling system.

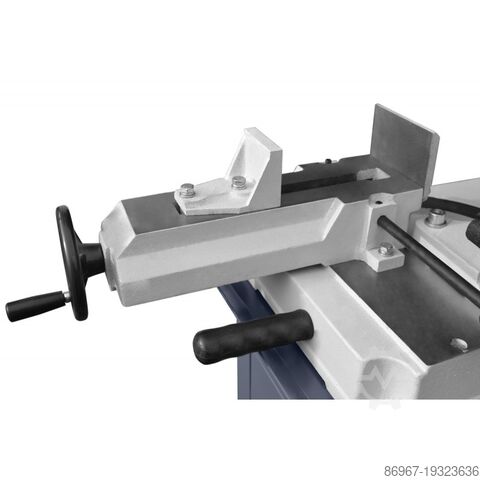

The saw arm is made from a single-piece cast iron and, combined with the 27 mm cutting band used in this model, enables full-volume batch cutting of profiles and solid materials. The vise is positioned on an adjustable bed and features a quick-release clamp. Blade guides are fitted with hard metal - carbide inserts and a rolling bearing system. It is precisely the CARBIDE BLADE GUIDES that ensure cut precision and straightness.

The arm features an automatic blade tension sensor and is inclined at 25 degrees to increase blade longevity. A cleaning brush is mounted under the arm to keep the blade clean and in optimal condition. Machine drive is transmitted via a worm gear.

A cast iron worktable is attached to the base with a swiveling arm and a control panel on a separate arm. During the cutting process, the main cutting motion is the movement of the cutting band, with the feed movement provided by the descent of the arm. The descent speed of the arm (cutting speed) is controlled via a hydraulic cylinder.

Feed speed is adjusted from the saw's control panel. Two cutting band speeds are available: 37.5 and 75 m/min. When the arm reaches its lowest position (after cutting), the cutting band drive is switched off automatically. Safety is ensured by blade guards and micro-switches that stop the motor after the cutting cycle is completed or any guard is opened; there is an additional safety feature that automatically stops the saw in case the band breaks.

Pgedpeudi Unefx Adysg

The drive is transmitted via a motor with a worm gear.

The motor is equipped with a thermal fuse to protect against overheating during operation.

Technical data

TOTAL POWER: 1.5 kW

SUPPLY: 400V 50Hz

ARM DESCENT CONTROL: hydraulic cylinder

BLADE DIMENSIONS: 2450 x 27 x 0.9 mm

BLADE SPEED: 37.5 / 75 m/min

VISE BASE HEIGHT: 900 mm

MACHINE DIMENSIONS (ARM UP) (L x W x H): 1720 x 800 x 1800 mm

WEIGHT: 215 kg

Cutting Capacity

ANGLE Round [mm] Rectangular [mm] Square [mm]

0º ø220 260 x 140 200 x 200

45º R ø160 160 x 140 160 x 160

60º R ø100 120 x 100 100 x 100

The price does not apply to machines purchased in Poland.

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Machine Features

This horizontal metal bandsaw with a swiveling arm allows cutting at right angles to the material axis as well as at any angle from 0 to 60°. Materials can be fed manually or using any mechanical device, while the tool feed occurs automatically. The blade guides feature special carbide pads and bearings, significantly affecting blade guidance, longevity, straightness, and cutting accuracy and quality. Carbide guidance greatly reduces machine and blade wear. The machine is equipped with a high-efficiency coolant pump in a closed-loop cooling system.

The saw arm is made from a single-piece cast iron and, combined with the 27 mm cutting band used in this model, enables full-volume batch cutting of profiles and solid materials. The vise is positioned on an adjustable bed and features a quick-release clamp. Blade guides are fitted with hard metal - carbide inserts and a rolling bearing system. It is precisely the CARBIDE BLADE GUIDES that ensure cut precision and straightness.

The arm features an automatic blade tension sensor and is inclined at 25 degrees to increase blade longevity. A cleaning brush is mounted under the arm to keep the blade clean and in optimal condition. Machine drive is transmitted via a worm gear.

A cast iron worktable is attached to the base with a swiveling arm and a control panel on a separate arm. During the cutting process, the main cutting motion is the movement of the cutting band, with the feed movement provided by the descent of the arm. The descent speed of the arm (cutting speed) is controlled via a hydraulic cylinder.

Feed speed is adjusted from the saw's control panel. Two cutting band speeds are available: 37.5 and 75 m/min. When the arm reaches its lowest position (after cutting), the cutting band drive is switched off automatically. Safety is ensured by blade guards and micro-switches that stop the motor after the cutting cycle is completed or any guard is opened; there is an additional safety feature that automatically stops the saw in case the band breaks.

Pgedpeudi Unefx Adysg

The drive is transmitted via a motor with a worm gear.

The motor is equipped with a thermal fuse to protect against overheating during operation.

Technical data

TOTAL POWER: 1.5 kW

SUPPLY: 400V 50Hz

ARM DESCENT CONTROL: hydraulic cylinder

BLADE DIMENSIONS: 2450 x 27 x 0.9 mm

BLADE SPEED: 37.5 / 75 m/min

VISE BASE HEIGHT: 900 mm

MACHINE DIMENSIONS (ARM UP) (L x W x H): 1720 x 800 x 1800 mm

WEIGHT: 215 kg

Cutting Capacity

ANGLE Round [mm] Rectangular [mm] Square [mm]

0º ø220 260 x 140 200 x 200

45º R ø160 160 x 140 160 x 160

60º R ø100 120 x 100 100 x 100

The price does not apply to machines purchased in Poland.

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Ponudnik

Opomba: Brezplačno se registrirajte ali prijavite, za dostop do vseh informacij.

Pošlji zahtevo

Telefon & Faks

+48 25 63... oglasi

Ti oglasi bi vas prav tako lahko zanimali.

Mali oglas

Wymysłów

Wymysłów

701 km

Držalo za orodje

ORION SK40 DIN 69871 AD + wiertło HSS fi

ORION SK40 DIN 69871 AD + wiertło HSS fi

Mali oglas

Siedlce

Siedlce

853 km

Tračna žaga

CORMAKBS-128HDRC 400V

CORMAKBS-128HDRC 400V

Mali oglas

Mindelheim

Mindelheim

400 km

Tračna žaga

MIOTAL®S 170 G

MIOTAL®S 170 G

Mali oglas

Nemčija

Nemčija

614 km

Sredinski stružnica in stružnica za vreteno

STRUNGURI ARADSN501x1500

STRUNGURI ARADSN501x1500

Mali oglas

Schlüchtern

Schlüchtern

619 km

UMENJA

Voest AlpineDA 160

Voest AlpineDA 160

Mali oglas

Wien

Wien

245 km

Varilna enota

FRONIUS TPS 5000 MIG MAG PULSTRANS PULS SYNERGIC 5000 / 500 MASCHINE

FRONIUS TPS 5000 MIG MAG PULSTRANS PULS SYNERGIC 5000 / 500 MASCHINE

Mali oglas

Wiesbaden

Wiesbaden

667 km

Stebrni vrtalnik

IXIONBSS-23 AV

IXIONBSS-23 AV

Mali oglas

Nemčija

Nemčija

650 km

Sredinski stružnica in stružnica za vreteno

PADOVANILABOR 230

PADOVANILABOR 230

Mali oglas

Böblingen

Böblingen

533 km

Tračna žaga

ZIMMERZ 241-1/R

ZIMMERZ 241-1/R

Mali oglas

Eislingen/Fils

Eislingen/Fils

489 km

Oddelek strižne - skupaj

PEDDINGHAUS210/13

PEDDINGHAUS210/13

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake