Horizontalni pakirni strojAMTEC

HPFS MINI PG15-L

Horizontalni pakirni stroj

AMTEC

HPFS MINI PG15-L

Leto izdelave

2025

Stanje

Novo

Lokacija

Hamburg

Prikaži slike

Prikaži karto

Podatki o stroju

- Opis stroja:

- Horizontalni pakirni stroj

- Proizvajalec:

- AMTEC

- Model:

- HPFS MINI PG15-L

- Leto izdelave:

- 2025

- Stanje:

- novo

Cena in lokacija

- Lokacija:

- Hamburg

Klic

Podrobnosti ponudbe

- ID ponudbe:

- A18720056

- Št. reference:

- GE-HP0408-DOY-2FL

- Nazadnje posodobljeno:

- dne 14.03.2025

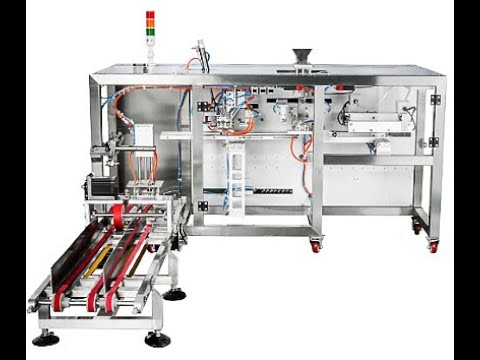

Opis

Horizontal packaging machine including auger filler and linear weigher for dosing and packaging granulates and powdery products into pre-made bags. MINI VERSION for pre-made doypacks, block-bottom bags, or flat pouches. Modules for specific bag features such as zip/press closures, screw caps (spout), and gusseted shapes can be integrated; optional: batch/date printer and gas flushing module. Bag detectors check the correct placement and full opening of the doypack. Immediately after detecting the bag, the product is dispensed into the bag via the filling spout. The sealing area remains clean during this process. A special gripper system holds the stand-up pouch precisely in position during filling, before the doypack is closed and sealed. MITSUBISHI PLC, SMC vacuum filter, OMRON PID temperature control, AIRTAC cylinders.

– Specifications for the horizontal packaging machine: Stainless steel housing made of SUS304; maximum machine cycle rate (no load): 15 cycles/minute; bag width: 100–300 mm; bag length: 100–350 mm; compressed air requirement: 6.5 bar, 0.2 m³/min; power supply: 220V, single-phase, 1 kW; machine dimensions: approx. L1754 × W510 × H1617 mm.

Njdpfxjv Nll Eo Abbocl

– Specifications for the auger filler: Stainless steel SUS 304 construction; dosing range: 50–100 g; hopper capacity: 50 liters; hopper with side opening; accuracy: ±1.5%; maximum no-load cycle rate: 50 cycles/minute; PLC controlled; servo motor drive; power supply: 220V, single-phase.

– Specifications for the linear weigher: All parts in contact with product made of stainless steel 304; plastic dust cover; number of weighing heads: 4; weighing bucket volume: 0.5 L; weighing range: 10–150 g; accuracy: 0.2–1 g; maximum no-load cycle rate: 60 cycles/minute; operation via touchscreen; power supply: 220V, single-phase; mobile stainless steel frame (SUS304) included. Discharge conveyor for removal of finished bags is also included.

– Specifications: Stainless steel housing SUS304; 220V, single-phase, 0.5 kW.

The photo shows only the horizontal packaging machine. Additional photos available on request.

Please note that our new prices are often below usual used equipment prices. Just ask us and let us know your packaging requirements. – We typically have 30–50 different new machines available for immediate delivery from stock. For custom-built machines, we offer very short lead times starting at approx. 3 weeks. – All machines come with a full warranty.

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

– Specifications for the horizontal packaging machine: Stainless steel housing made of SUS304; maximum machine cycle rate (no load): 15 cycles/minute; bag width: 100–300 mm; bag length: 100–350 mm; compressed air requirement: 6.5 bar, 0.2 m³/min; power supply: 220V, single-phase, 1 kW; machine dimensions: approx. L1754 × W510 × H1617 mm.

Njdpfxjv Nll Eo Abbocl

– Specifications for the auger filler: Stainless steel SUS 304 construction; dosing range: 50–100 g; hopper capacity: 50 liters; hopper with side opening; accuracy: ±1.5%; maximum no-load cycle rate: 50 cycles/minute; PLC controlled; servo motor drive; power supply: 220V, single-phase.

– Specifications for the linear weigher: All parts in contact with product made of stainless steel 304; plastic dust cover; number of weighing heads: 4; weighing bucket volume: 0.5 L; weighing range: 10–150 g; accuracy: 0.2–1 g; maximum no-load cycle rate: 60 cycles/minute; operation via touchscreen; power supply: 220V, single-phase; mobile stainless steel frame (SUS304) included. Discharge conveyor for removal of finished bags is also included.

– Specifications: Stainless steel housing SUS304; 220V, single-phase, 0.5 kW.

The photo shows only the horizontal packaging machine. Additional photos available on request.

Please note that our new prices are often below usual used equipment prices. Just ask us and let us know your packaging requirements. – We typically have 30–50 different new machines available for immediate delivery from stock. For custom-built machines, we offer very short lead times starting at approx. 3 weeks. – All machines come with a full warranty.

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Ponudnik

Opomba: Brezplačno se registrirajte ali prijavite, za dostop do vseh informacij.

Registriran od: 2006

Pošlji zahtevo

Telefon & Faks

+49 40 33... oglasi

Ti oglasi bi vas prav tako lahko zanimali.

Mali oglas

Mala Vranjska

Mala Vranjska

403 km

Vakuumski boben

Vacuum tumbler1700 liters

Vacuum tumbler1700 liters

Mali oglas

Nemčija

Nemčija

650 km

Stroj za pakiranje vrečk

MerzMP-2

MerzMP-2

Mali oglas

Schwalmtal

Schwalmtal

853 km

Paletna naprava

QTMUNIPAL

QTMUNIPAL

Mali oglas

Krotoszyn

Krotoszyn

643 km

Vakuumski polnilnik

VemagHP 20E

VemagHP 20E

Mali oglas

Spanbroek

Spanbroek

1.027 km

Krivulja valjarja

'Vanderlande' Rollenbahn | Rollenbahnkurven

'Vanderlande' Rollenbahn | Rollenbahnkurven

Mali oglas

Lipsko

Lipsko

789 km

Polnilna linija / Hamburger linija

VemagHP20E/FM250

VemagHP20E/FM250

Mali oglas

Krotoszyn

Krotoszyn

643 km

Polnilo VEMAGHP20E, pekarski model

VemagHP20E

VemagHP20E

Mali oglas

Krotoszyn

Krotoszyn

643 km

Amoniak spiralna zamrzovalnika, 2 kosa.

Frigoscandia, SabroeGyrocompact GC76, SAB163HF

Frigoscandia, SabroeGyrocompact GC76, SAB163HF

Mali oglas

Heerhugowaard

Heerhugowaard

1.033 km

Stroj za tesnjenje

Angelus60l can seamer

Angelus60l can seamer

Mali oglas

Suffolk

Suffolk

1.237 km

Multivac linija za zapiranje pladnjev iz leta 2016 z manj kot 2000 delovnimi urami

MultivacT700

MultivacT700

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake