Depanelizacija / Obdelava tiskanih vezijSystemtechnik Hölzer GmbH

Nutzentrenner LOW 4233 XL RD

Depanelizacija / Obdelava tiskanih vezij

Systemtechnik Hölzer GmbH

Nutzentrenner LOW 4233 XL RD

Leto izdelave

2025

Stanje

Novo

Lokacija

Kronberg im Taunus

Prikaži slike

Prikaži karto

Podatki o stroju

- Opis stroja:

- Depanelizacija / Obdelava tiskanih vezij

- Proizvajalec:

- Systemtechnik Hölzer GmbH

- Leto izdelave:

- 2025

- Stanje:

- novo

- Funkcionalnost:

- popolnoma funkcionalen

Cena in lokacija

- Lokacija:

- Westerbachstraße 4, 61476 Kronberg im Taunus, Deutschland

Klic

Podrobnosti ponudbe

- ID ponudbe:

- A18369436

- Št. reference:

- LOW4233 RD XL Leiterplatten Nutzentrenner

- Nazadnje posodobljeno:

- dne 14.08.2025

Opis

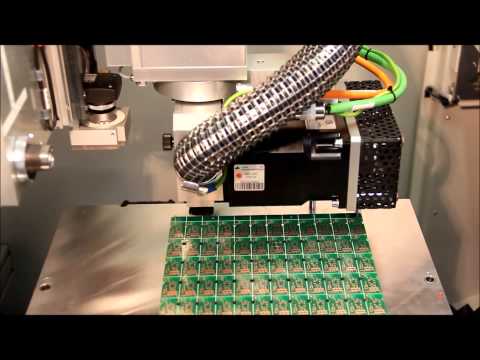

Semi-automatic Depaneling / Base Machine with Parallel Shuttle

The dynamic depaneling machine LOW 4322 XL is specifically designed for medium to high product volumes and meets increasing demands in the production process. PCB panels of various material types are separated using low-dust and low-stress sawing and milling technologies, ensuring maximum product flexibility, precision, and throughput. Highly dynamic linear motor axes, tooling, and grippers satisfy the highest quality standards and guarantee long service life and reliability for the depaneling solution.

Semi-automatic Depaneling – Solutions on Demand

The LOW 4322 XL depaneling machine allows for rapid product changeover while maintaining short separation and handling times. Panelized PCBs are loaded via a parallel shuttle, clamped using pin clamping technology and, if necessary, in combination with vacuum suction cups.

Made in Germany

The machine is equipped with:

• A shaft and disc tool separation module on the Z-axis (automatically rotatable 0-90°)

• X-Y cross table module with linear motor technology and high-resolution measuring system

• Dual loading module configured as a parallel shuttle, separated left and right with sliding doors

• Steel welded frame with two maintenance doors – left and right. ESD

• Standard vision system base module for teach-in programming

• Working area: 520 x 480 mm

• Automatic milling cutter length processing

• Remote maintenance/support via remote connection

• Touch IPC with Windows 10 Pro operating system

• Laser axis measurement including protocol

Kedpfx Abovuw R Rjbjwt

• Air ionization

• Milling cutter breakage monitoring (shaft milling cutters only)

• Prepared for vacuum clamping technology

• ESD powder coating, RAL 9002, including window and sliding doors

An optional dust extraction unit can be offered retrospectively.

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

The dynamic depaneling machine LOW 4322 XL is specifically designed for medium to high product volumes and meets increasing demands in the production process. PCB panels of various material types are separated using low-dust and low-stress sawing and milling technologies, ensuring maximum product flexibility, precision, and throughput. Highly dynamic linear motor axes, tooling, and grippers satisfy the highest quality standards and guarantee long service life and reliability for the depaneling solution.

Semi-automatic Depaneling – Solutions on Demand

The LOW 4322 XL depaneling machine allows for rapid product changeover while maintaining short separation and handling times. Panelized PCBs are loaded via a parallel shuttle, clamped using pin clamping technology and, if necessary, in combination with vacuum suction cups.

Made in Germany

The machine is equipped with:

• A shaft and disc tool separation module on the Z-axis (automatically rotatable 0-90°)

• X-Y cross table module with linear motor technology and high-resolution measuring system

• Dual loading module configured as a parallel shuttle, separated left and right with sliding doors

• Steel welded frame with two maintenance doors – left and right. ESD

• Standard vision system base module for teach-in programming

• Working area: 520 x 480 mm

• Automatic milling cutter length processing

• Remote maintenance/support via remote connection

• Touch IPC with Windows 10 Pro operating system

• Laser axis measurement including protocol

Kedpfx Abovuw R Rjbjwt

• Air ionization

• Milling cutter breakage monitoring (shaft milling cutters only)

• Prepared for vacuum clamping technology

• ESD powder coating, RAL 9002, including window and sliding doors

An optional dust extraction unit can be offered retrospectively.

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Ponudnik

Opomba: Brezplačno se registrirajte ali prijavite, za dostop do vseh informacij.

Registriran od: 2018

Pošlji zahtevo

Telefon & Faks

+49 6173 ... oglasi

Ti oglasi bi vas prav tako lahko zanimali.

Mali oglas

Barbing

Barbing

380 km

Dvostranski stroj za brušenje stekla

Schiatti AngeloBFP12

Schiatti AngeloBFP12

Mali oglas

Matelica (MC)

Matelica (MC)

357 km

LASERSKI REZALNI STROJI - LASERSKI REZANJE Z VLAKNI

PRIMA POWERPLATINO FIBER 1530

PRIMA POWERPLATINO FIBER 1530

Mali oglas

Nemčija

Nemčija

796 km

Premazni sistem Venjakob Perfect, OIR, AirJet, UV

VenjakobVEN SPRAY and Drying, UV Line

VenjakobVEN SPRAY and Drying, UV Line

Mali oglas

Butzbach

Butzbach

667 km

Obdelovalni center

Starrag-HeckertHEC500D

Starrag-HeckertHEC500D

Mali oglas

Borken

Borken

868 km

Steklo, laminiranje linijo z 2 grelniki

Tool-TempHVD-G02

Tool-TempHVD-G02

Mali oglas

Burghaun

Burghaun

637 km

Morski zabojnik

db-container20fuß

db-container20fuß

Mali oglas

Bad Waltersdorf

Bad Waltersdorf

138 km

Dvigalna miza za rezanje stekla

Hegla

Hegla

Mali oglas

Władysławowo

Władysławowo

943 km

Steklo

DIP TECHGlassJet NOVO

DIP TECHGlassJet NOVO

Mali oglas

Butzbach

Butzbach

667 km

Obdelovalni center

Starrag-HeckertHEC400D

Starrag-HeckertHEC400D

Mali oglas

Herzogenrath

Herzogenrath

840 km

Stroj za vrtanje stekla

SchramlTop Clear 13 Special- 4

SchramlTop Clear 13 Special- 4

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake