Biesse Artech Akron 440 nakup rabljenega (331)

Pollenzo

Pollenzo HSD PE 106 MODUL

BIESSE

Pollenzo

Pollenzo MOD.PE222 GTD06

BIESSE

Pollenzo

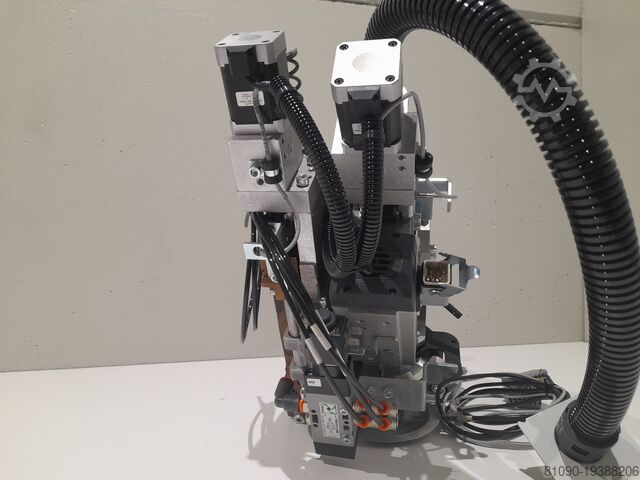

Pollenzo KOMPLET GLAVA 4 VRETENA

BIESSE

+44 20 806 810 84

Pollenzo

Pollenzo 6 VRETENA VRTALNA GLAVA BIESSE

BIESSE

Pollenzo

Pollenzo Zgornja skupina za odstranjevanje klasja

BIESSE

Pollenzo

Pollenzo LEVA GLAVA 7 TOČK

BIESSE

Pollenzo

Pollenzo TEST. PRIKLJUČEK ZA 4 VRETENA, POSEBNI, 2. KORAK 57

BIESSE

Pollenzo

Pollenzo 3-TOČKOVA GLAVA MC

BIESSE

Pollenzo

Pollenzo MOD.PE302A 8 IZV

BIESSE

Pollenzo

Pollenzo MOD.PE302A 8 IZV

BIESSE

Pollenzo

Pollenzo MOD.PE323A

BIESSE

Pollenzo

Pollenzo MOD.PE222 GTD06

BIESSE

Pollenzo

Pollenzo PRISESKA KOŽA, VEŠENA 131,5 X 75 X 48

BIESSE

Pollenzo

Pollenzo MOT. SM137 R=1:8

BIESSE

Pollenzo

Pollenzo TEST.SPECIALNI PRIKLJUČEK ZA 6 VRETEN 3 KORAK 57

BIESSE

Pollenzo

Pollenzo Robni brusilnik

BIESSE

Pollenzo

Pollenzo KOMPLET GLAVA 3 CENTRIRNA VRETENA S

biesse

Pollenzo

Pollenzo R25 SPONKA GLAVA

BIESSE

Pollenzo

Pollenzo 6 TOČK TETINA

BIESSE

Pollenzo

Pollenzo BIESSE OBREZNI AGREGAT

BIESSE

Pollenzo

Pollenzo Robni brusilnik

BIESSE

Pollenzo

Pollenzo MOD.PE323A

BIESSE

Pollenzo

Pollenzo 7-VRETENA VRTALNA GLAVA BIESSE

BIESSE

Pollenzo

Pollenzo 3-TOČKOVA GLAVA

BIESSE

Pollenzo

Pollenzo HSK AGREGAT

BIESSE

Rabljeni Biesse Artech Akron 440 (331)

Zdaj preiščite celoten Machineseeker z več kot 200.000 rabljenimi stroji.Brskajte po najbolj priljubljenih poimenovanjih strojev:

+44 20 806 810 84