Stroj za preskušanje zobnikovKLINGELNBERG

PFSU 1600

Stroj za preskušanje zobnikov

KLINGELNBERG

PFSU 1600

Leto izdelave

1975

Stanje

Rabljeno

Lokacija

Metzingen

Prikaži slike

Prikaži karto

Podatki o stroju

- Opis stroja:

- Stroj za preskušanje zobnikov

- Proizvajalec:

- KLINGELNBERG

- Model:

- PFSU 1600

- Leto izdelave:

- 1975

- Stanje:

- rabljeno

Cena in lokacija

- Lokacija:

- Metzingen

Klic

Podrobnosti ponudbe

- ID ponudbe:

- A16566671

- Št. reference:

- 1049-422129

- Nazadnje posodobljeno:

- dne 18.07.2024

Opis

Wheel diameter – max. 160 - 1,600 mm

Wheel width 250 mm

Module – max. 20

Module – min. 1.5

Total power requirement 1 kW

Machine weight approx. 3 t

Space required approx. ... m

K L I N G E L N B E R G

Universal Gear Testing Machine for Involute and Helix Testing, Type PFSU 1600

Year of manufacture 1975, modernised in 1995 #B 2281

Working range:

min./max. gear diameter: 160 – 1,600 mm

Module range: 1.5 – 20 mm

Maximum face width: 250 mm

Measuring carriage stroke approx.: 300 mm

Ledpfst Hwptsx Abberg

Maximum helix angle: 0 – 90°

Maximum centre distance in between centers: approx. 1,150 mm

Overhang of the tailstock: 450 mm

Chart recorder magnification: 50/250/500/1000 x

Maximum test gear weight: approx. 4,000 kg

Weight: approx. 3,000 kg

Total drive: approx. 1 kW – 380 V – 50 Hz /

Suitable for testing:

- Tooth profile (involute)

- Tooth direction (helix angle/lead) on internal and external gears, hobs, shaper cutters, worm gears, etc.

- Tooth runout, surface roughness

- Determination/reconstruction of the base circle and helix angle, etc.

Accessories / special equipment:

- Optical base circle setting and optical angle setting (no longer using base-circle discs)

- High workpiece weight possible due to specific construction, testing sequence motorised or manual via handwheels

- Rotatable mounting turntable Ø 480 mm for mounting larger gear blanks, with 2 sets of different extension supports (400 and 470 mm long) for max. gear diameter of 1,600 mm

- Counterholder AV 17 for max. workpiece length of 1,150 mm

- Separate electrical cabinet for control of manual movements as well as

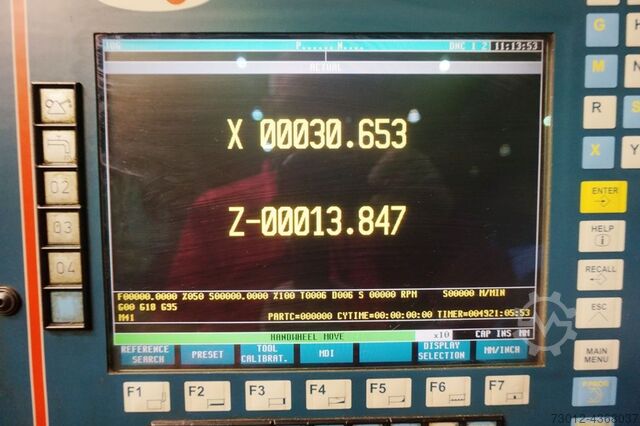

- GFM Computer Type ZMP 20 e with software for automatic gear measurement, updated in English and optionally in German, program update to current version V 21.17, ideal for generating modern test reports with graphics, graphical display on monitor, other subprograms, HP printer, flat screen

- Various probe inserts, small parts, height-adjustable mount for a pitch measurement device (rear mounted), leveling feet, etc.

- However, pitch measurement device not included. Mounting fixture available and installed at rear.

Condition: Very good – ready for demonstration, dismantled and reassembled by specialist.

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Wheel width 250 mm

Module – max. 20

Module – min. 1.5

Total power requirement 1 kW

Machine weight approx. 3 t

Space required approx. ... m

K L I N G E L N B E R G

Universal Gear Testing Machine for Involute and Helix Testing, Type PFSU 1600

Year of manufacture 1975, modernised in 1995 #B 2281

Working range:

min./max. gear diameter: 160 – 1,600 mm

Module range: 1.5 – 20 mm

Maximum face width: 250 mm

Measuring carriage stroke approx.: 300 mm

Ledpfst Hwptsx Abberg

Maximum helix angle: 0 – 90°

Maximum centre distance in between centers: approx. 1,150 mm

Overhang of the tailstock: 450 mm

Chart recorder magnification: 50/250/500/1000 x

Maximum test gear weight: approx. 4,000 kg

Weight: approx. 3,000 kg

Total drive: approx. 1 kW – 380 V – 50 Hz /

Suitable for testing:

- Tooth profile (involute)

- Tooth direction (helix angle/lead) on internal and external gears, hobs, shaper cutters, worm gears, etc.

- Tooth runout, surface roughness

- Determination/reconstruction of the base circle and helix angle, etc.

Accessories / special equipment:

- Optical base circle setting and optical angle setting (no longer using base-circle discs)

- High workpiece weight possible due to specific construction, testing sequence motorised or manual via handwheels

- Rotatable mounting turntable Ø 480 mm for mounting larger gear blanks, with 2 sets of different extension supports (400 and 470 mm long) for max. gear diameter of 1,600 mm

- Counterholder AV 17 for max. workpiece length of 1,150 mm

- Separate electrical cabinet for control of manual movements as well as

- GFM Computer Type ZMP 20 e with software for automatic gear measurement, updated in English and optionally in German, program update to current version V 21.17, ideal for generating modern test reports with graphics, graphical display on monitor, other subprograms, HP printer, flat screen

- Various probe inserts, small parts, height-adjustable mount for a pitch measurement device (rear mounted), leveling feet, etc.

- However, pitch measurement device not included. Mounting fixture available and installed at rear.

Condition: Very good – ready for demonstration, dismantled and reassembled by specialist.

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Ponudnik

Pošlji zahtevo

Telefon & Faks

+49 7123 ... oglasi

Ti oglasi bi vas prav tako lahko zanimali.

Mali oglas

Hilden

Hilden

813 km

Stroj za testiranje stožčastih zobnikov

KLINGELNBERG-OERLIKONT60 A

KLINGELNBERG-OERLIKONT60 A

Mali oglas

Kanada

Kanada

7.993 km

Stroj za merjenje zobnikov

KLINGELNBERG-OERLIKONCS 200

KLINGELNBERG-OERLIKONCS 200

Mali oglas

Grüsch

Grüsch

415 km

Stroj za brušenje stožčastih zobnikov

KLINGELNBERGG 27

KLINGELNBERGG 27

Mali oglas

Dreieich

Dreieich

637 km

Pehanje stroj-notranje - navpično

CARDINAL

CARDINAL

Mali oglas

Tönisvorst

Tönisvorst

849 km

Stroj za rezkanje zobnikov - vertikalni

PFAUTERP 1503/1800 B

PFAUTERP 1503/1800 B

Mali oglas

București

București

891 km

Generator zobnikov s ribjo kostjo MDV 2000

1 MaiMDV 2000

1 MaiMDV 2000

Mali oglas

Fuente de Cantos

Fuente de Cantos

1.957 km

Stroji za oblikovanje zobnikov

DEMMOF7280

DEMMOF7280

Mali oglas

Malsch

Malsch

586 km

Stroj za preskušanje zobnikov

MAHRPrimar GMX 600

MAHRPrimar GMX 600

Mali oglas

Haiger

Haiger

715 km

CNC stružnica

PinachoCobra 180

PinachoCobra 180

Mali oglas

Metzingen

Metzingen

506 km

Oblikovalec zobnikov

LORENZLS 400

LORENZLS 400

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake