Klasifikacijski mlinHosokawa Alpine

ZPS 315

Klasifikacijski mlin

Hosokawa Alpine

ZPS 315

Leto izdelave

1991

Stanje

Rabljeno

Lokacija

Augsburg

Prikaži slike

Prikaži karto

Podatki o stroju

- Opis stroja:

- Klasifikacijski mlin

- Proizvajalec:

- Hosokawa Alpine

- Model:

- ZPS 315

- Leto izdelave:

- 1991

- Stanje:

- generalkompletno obnovljen (rabljeno)

Cena in lokacija

- Lokacija:

- Peter-Dörfler-Straße 13-25, 86199 Augsburg, DE

Klic

Prodaja strojev

Ste že objavili oglas za svojo rabljeno napravo?

Prodajte prek Machineseeker brez provizije.

Več o prodaji strojev

Več o prodaji strojev

Podrobnosti ponudbe

- ID ponudbe:

- A9622523

- Nazadnje posodobljeno:

- dne 10.02.2025

Opis

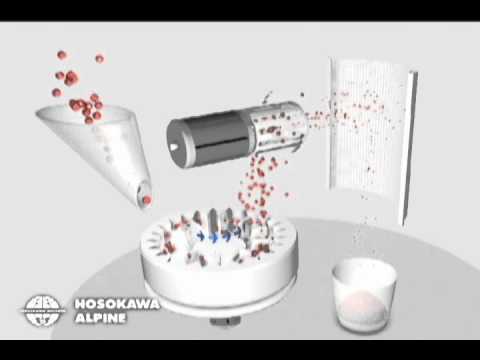

Used Hosokawa Alpine Zirkoplex ZPS 315 Classifier Mill

A HOSOKAWA ALPINE Originals machine

Refurbished by the original manufacturer

Exclusive use of original components

Original manufacturer’s warranty

Spare parts supply guaranteed by the manufacturer

Reduced delivery time

Before delivery, the machine is inspected, all wear parts are checked and replaced if necessary, and the machine is customized to your specific requirements

Option to supply all required peripherals or to adapt to your existing production plant

We are also interested in repurchasing any unused HOSOKAWA ALPINE equipment

The Hosokawa Alpine Zirkoplex ZPS classifier impact mill is perfect for fine grinding of various dry materials with precise control of cut point or maximum particle size thanks to the integrated classifier wheel design. It can be used to micronize various products and is suitable for different industries where fine grinding is required, such as minerals, chemicals, food, pharmaceuticals, and more. Grinding occurs at the lower part of the mill where a rotating plate equipped with grinding tools (hammers or pins) impacts and accelerates particles against the internal grinding track (liner) to break them down. Airflow within the chamber transports the fines to the classifier wheel where unwanted coarse particles are rejected for further grinding, while the fine particles pass through to the next process step, usually filtration. Thanks to the process air required for operation, only minimal temperature increase is expected during grinding compared to other milling technologies. Final particle size distribution can be easily adjusted by changing parameters such as grinding rotor speed, classifier wheel speed, air volume, feed rate, etc.

Construction material: mild steel

No wear protection

Machine without explosion protection (NPSR), not ATEX certified

Scope of supply:

Hosokawa Alpine ZPS 315 mill with motors, one set of internal grinding tools, and mounting frame

Fgedpfxslgy U Nj Ah Deh

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

A HOSOKAWA ALPINE Originals machine

Refurbished by the original manufacturer

Exclusive use of original components

Original manufacturer’s warranty

Spare parts supply guaranteed by the manufacturer

Reduced delivery time

Before delivery, the machine is inspected, all wear parts are checked and replaced if necessary, and the machine is customized to your specific requirements

Option to supply all required peripherals or to adapt to your existing production plant

We are also interested in repurchasing any unused HOSOKAWA ALPINE equipment

The Hosokawa Alpine Zirkoplex ZPS classifier impact mill is perfect for fine grinding of various dry materials with precise control of cut point or maximum particle size thanks to the integrated classifier wheel design. It can be used to micronize various products and is suitable for different industries where fine grinding is required, such as minerals, chemicals, food, pharmaceuticals, and more. Grinding occurs at the lower part of the mill where a rotating plate equipped with grinding tools (hammers or pins) impacts and accelerates particles against the internal grinding track (liner) to break them down. Airflow within the chamber transports the fines to the classifier wheel where unwanted coarse particles are rejected for further grinding, while the fine particles pass through to the next process step, usually filtration. Thanks to the process air required for operation, only minimal temperature increase is expected during grinding compared to other milling technologies. Final particle size distribution can be easily adjusted by changing parameters such as grinding rotor speed, classifier wheel speed, air volume, feed rate, etc.

Construction material: mild steel

No wear protection

Machine without explosion protection (NPSR), not ATEX certified

Scope of supply:

Hosokawa Alpine ZPS 315 mill with motors, one set of internal grinding tools, and mounting frame

Fgedpfxslgy U Nj Ah Deh

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Ponudnik

Opomba: Brezplačno se registrirajte ali prijavite, za dostop do vseh informacij.

Registriran od: 2019

Pošlji zahtevo

Telefon & Faks

+49 821 2... oglasi

Ti oglasi bi vas prav tako lahko zanimali.

mali oglas

Augsburg

Augsburg

396 km

Klasifikacijski mlin

Hosokawa AlpineZPS 315

Hosokawa AlpineZPS 315

mali oglas

Arnsberg

Arnsberg

781 km

Klasirni mlin

Hosokawa AlpineZPS 315

Hosokawa AlpineZPS 315

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake