Ravna matrica, vroče žigosanje, multiGRAFOTRONIC

350 200254G

Ravna matrica, vroče žigosanje, multi

GRAFOTRONIC

350 200254G

Začetna cena brez DDV

67.500 €

Stanje

Rabljeno

Lokacija

Kruszyn Krajeński

Prikaži slike

Prikaži karto

Podatki o stroju

- Opis stroja:

- Ravna matrica, vroče žigosanje, multi

- Proizvajalec:

- GRAFOTRONIC

- Model:

- 350 200254G

- Stanje:

- zelo dobro (rabljeno)

- Funkcionalnost:

- popolnoma funkcionalen

Cena in lokacija

Začetna cena brez DDV

67.500 €

- Lokacija:

- Ceramiczna 15, 86-005 Białe Błota, PL

Klic

Podrobnosti ponudbe

- ID ponudbe:

- A18949116

- Nazadnje posodobljeno:

- dne 29.12.2025

Opis

Segment I – Unwinder with Stabilizing Table

The first segment is responsible for stable web handling. It is equipped with shafts that allow both lamination and delamination of the face and liner or other raw materials. The segment features a laminator with precise pressure adjustment.

Additionally:

• A dancer mechanism in each segment enables continuous operation, eliminating the need to stop the machine during flatbed die cutting.

• Servo-driven pull rollers ensure precise material control and are also located in the station.

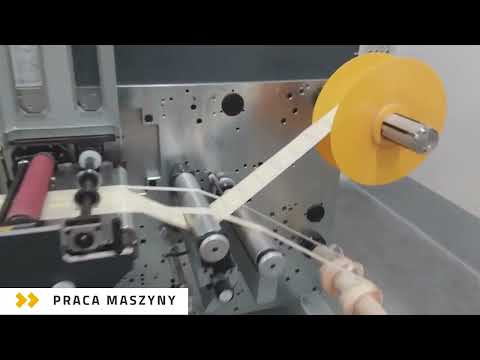

Segment II – Central Unit (Flatbed Die Cutter)

The heart of the machine is the flatbed die cutter, which enables both cutting and embossing.

It is equipped with:

• Hot stamping system – a heated plate with a mounted die allows for decorative foiling.

• Top film unwinders for additional substrate processing.

• Manual pressure adjustment – four independent gauges provide complete control over the process, essential for irregular dies and unconventional jobs.

• Lower carriage as an alternative to the dancer system, used depending on job requirements.

Segment III – Puncher

The third segment is responsible for the separation of cut labels and their transfer to the collection tray.

• Puncher – ensures precise separation of individual labels.

• Two laminators – one on each side of the puncher, each with adjustable pressure.

• Unwinders and rewinders ensure smooth handling of additional material.

Segment IV – Rewinder

The final segment is responsible for rewinding the finished material.

Ppjdpjwck U Rsfx Aczsl

Equipped with:

• Two shafts – enabling simultaneous or alternate rewinding of the finished product.

• Web tensioning system (nipping and tension rollers) – ensures stable material handling.

• Slitting station with rotary knives.

• Matrix removal (waste extraction) system.

• Web sensors placed under each dancer, providing optimal process control.

Additional functionalities

• Remote control – the machine can be operated via an included tablet.

• Register sensor system – precisely aligns pre-printed material, ensuring high accuracy and repeatability in production.

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

The first segment is responsible for stable web handling. It is equipped with shafts that allow both lamination and delamination of the face and liner or other raw materials. The segment features a laminator with precise pressure adjustment.

Additionally:

• A dancer mechanism in each segment enables continuous operation, eliminating the need to stop the machine during flatbed die cutting.

• Servo-driven pull rollers ensure precise material control and are also located in the station.

Segment II – Central Unit (Flatbed Die Cutter)

The heart of the machine is the flatbed die cutter, which enables both cutting and embossing.

It is equipped with:

• Hot stamping system – a heated plate with a mounted die allows for decorative foiling.

• Top film unwinders for additional substrate processing.

• Manual pressure adjustment – four independent gauges provide complete control over the process, essential for irregular dies and unconventional jobs.

• Lower carriage as an alternative to the dancer system, used depending on job requirements.

Segment III – Puncher

The third segment is responsible for the separation of cut labels and their transfer to the collection tray.

• Puncher – ensures precise separation of individual labels.

• Two laminators – one on each side of the puncher, each with adjustable pressure.

• Unwinders and rewinders ensure smooth handling of additional material.

Segment IV – Rewinder

The final segment is responsible for rewinding the finished material.

Ppjdpjwck U Rsfx Aczsl

Equipped with:

• Two shafts – enabling simultaneous or alternate rewinding of the finished product.

• Web tensioning system (nipping and tension rollers) – ensures stable material handling.

• Slitting station with rotary knives.

• Matrix removal (waste extraction) system.

• Web sensors placed under each dancer, providing optimal process control.

Additional functionalities

• Remote control – the machine can be operated via an included tablet.

• Register sensor system – precisely aligns pre-printed material, ensuring high accuracy and repeatability in production.

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Ponudnik

Opomba: Brezplačno se registrirajte ali prijavite, za dostop do vseh informacij.

Registriran od: 2020

Pošlji zahtevo

Telefon & Faks

+48 52 37... oglasi

Ti oglasi bi vas prav tako lahko zanimali.

Mali oglas

Emskirchen

Emskirchen

495 km

Stroj za vstavljanje

Fracotyp-PostaliaFPi 4530

Fracotyp-PostaliaFPi 4530

Mali oglas

Slovenija

Slovenija

66 km

Rotacijsko izsekavanje z neprekinjenim zlagalnikom

RIETSTACKIRS 430

RIETSTACKIRS 430

Mali oglas

Budaors

Budaors

332 km

Barvni kopirni stroj A3

Konica MinoltaC558

Konica MinoltaC558

Mali oglas

Langenfeld (Rheinland)

Langenfeld (Rheinland)

808 km

Stroj za digitalno tiskanje

XeroxiGen 5 Press incl. 5th colour

XeroxiGen 5 Press incl. 5th colour

Mali oglas

Leinfelden-Echterdingen

Leinfelden-Echterdingen

522 km

FGT Grafični stroji - Obdelava

GMFB 3300 - Hotfoil/Screen etc.

GMFB 3300 - Hotfoil/Screen etc.

Mali oglas

München

München

340 km

PITNEY BOWES DI425

Pitney BowesDI425

Pitney BowesDI425

Mali oglas

Bad Kreuznach

Bad Kreuznach

670 km

Stroj za fleksotisk

SMO Sondermaschinenbau OscherslebenEDM 200

SMO Sondermaschinenbau OscherslebenEDM 200

Mali oglas

Kaunas

Kaunas

1.162 km

Rewer

Jurmet

Jurmet

Mali oglas

Leinfelden-Echterdingen

Leinfelden-Echterdingen

522 km

FGT Grafični stroji - Obdelava

GMDC 330 - Age: 2016!

GMDC 330 - Age: 2016!

Mali oglas

Leinfelden-Echterdingen

Leinfelden-Echterdingen

522 km

FGT grafični stroji - Oblikovalnica etiket

ROTOFLEXR 1300

ROTOFLEXR 1300

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake