Brusilnik s krtačoDANIBRUM

DAS LDX 1000 - 6

Brusilnik s krtačo

DANIBRUM

DAS LDX 1000 - 6

Leto izdelave

2025

Stanje

Novo

Lokacija

Vermești

Prikaži slike

Prikaži karto

Podatki o stroju

- Opis stroja:

- Brusilnik s krtačo

- Proizvajalec:

- DANIBRUM

- Model:

- DAS LDX 1000 - 6

- Leto izdelave:

- 2025

- Stanje:

- novo

- Funkcionalnost:

- popolnoma funkcionalen

Cena in lokacija

- Lokacija:

- Strada Combinatului, Bacău 605200, România

Klic

Podrobnosti ponudbe

- ID ponudbe:

- A19072501

- Nazadnje posodobljeno:

- dne 05.05.2025

Opis

Enhance Finish Quality with the DAS LDX 1000 – 6 Brush Sanding Machine

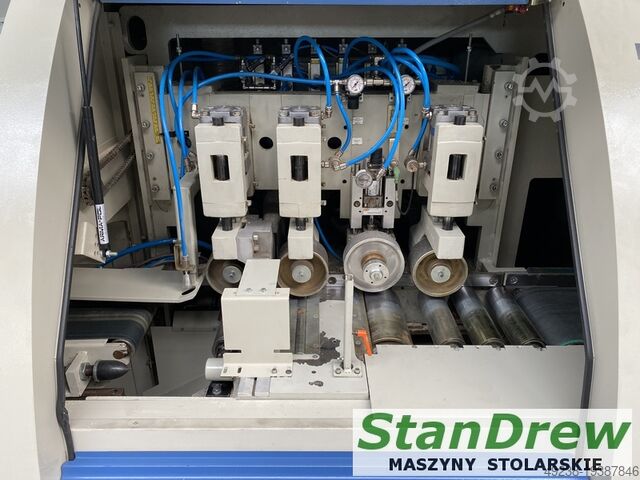

The automatic DAS LDX 1000 – 6 is engineered for precise sanding and finishing of profiled wooden or MDF components, delivering excellent results even for the highest aesthetic standards. It is ideal for smoothing, fine sanding, and final surface preparation, thanks to its versatile and robust configuration with 6 working units.

Standard equipment & technical features:

Multiple working units: longitudinal oscillating drums, oscillating pads, transverse drums with a Ø 280 mm and 1000 mm width, equipped with 20 helically mounted brushes.

Working capacity: Max. width 1000 mm, max. workpiece thickness 100 mm.

Efficient sanding: Disc rotation speed adjustable between 50 – 300 RPM via frequency inverter.

Sanding brushes: Adjustable length from 20 to 70 mm, allowing detailed work on profiles up to 8 mm deep.

Touchscreen control panel: Ergonomically positioned, allows independent control of each unit. User-friendly interface developed by DANIBRUM engineers for fast and efficient operation.

High-grip conveyor belt: Grooved rubber belt provides consistent feed, driven by a 1.1 kW motor. Includes automatic centering roller, height adjustment sensor, and dust-removal brushes at infeed and outfeed.

Professional sliding system: Ball recirculating bearings ensure precise, reliable movement and low maintenance. Manual lubrication.

Oscillation for sanding units: Ensures uniform finishing and extends the service life of abrasive belts and sisal brushes.

Efficient extraction system: Each group has dedicated extraction ports, connected to 8 x Ø 100 mm outlets, keeping the work area clean and efficient.

Quick side access: Large side openings allow easy brush change and rapid maintenance access.

Toothed belt transmission: Guarantees constant speed, stable drive, and low operating noise.

Finishing flexibility: The "fast release" system allows for quick changing of belts and brushes. Adaptable configuration suitable for various finishing styles and applications.

The DAS LDX 1000 – 6 is an efficient solution for manufacturers seeking superior quality in profiled wood processing, with high productivity and flawless finish.

Working width max.

1000 mm

Working height max.

100 mm

Longitudinal drum diameter (Ø)

220 mm

Longitudinal drum drive motor power – oscillating

2 x 1.5 kW

Oscillation motor power for longitudinal drums

0.55 kW

Ncsdpfxowhbtzs Abbjl

Oscillating pad diameter

200 mm

Oscillating pad drive motor power

1.5 kW

Oscillating pad oscillation motor power

0.18 kW

Transverse drum diameter (Ø)

280 mm

Transverse drum drive motor power

2 x 2.2 kW

Feed motor power

1.1 kW

Brush speed

max. 1000 rpm

Extraction port diameter (Ø)

4 x 100 mm

Overall dimensions

3300 x 1600 mm

Weight

1500 kg

Technical support available in Romanian, English or German.

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

The automatic DAS LDX 1000 – 6 is engineered for precise sanding and finishing of profiled wooden or MDF components, delivering excellent results even for the highest aesthetic standards. It is ideal for smoothing, fine sanding, and final surface preparation, thanks to its versatile and robust configuration with 6 working units.

Standard equipment & technical features:

Multiple working units: longitudinal oscillating drums, oscillating pads, transverse drums with a Ø 280 mm and 1000 mm width, equipped with 20 helically mounted brushes.

Working capacity: Max. width 1000 mm, max. workpiece thickness 100 mm.

Efficient sanding: Disc rotation speed adjustable between 50 – 300 RPM via frequency inverter.

Sanding brushes: Adjustable length from 20 to 70 mm, allowing detailed work on profiles up to 8 mm deep.

Touchscreen control panel: Ergonomically positioned, allows independent control of each unit. User-friendly interface developed by DANIBRUM engineers for fast and efficient operation.

High-grip conveyor belt: Grooved rubber belt provides consistent feed, driven by a 1.1 kW motor. Includes automatic centering roller, height adjustment sensor, and dust-removal brushes at infeed and outfeed.

Professional sliding system: Ball recirculating bearings ensure precise, reliable movement and low maintenance. Manual lubrication.

Oscillation for sanding units: Ensures uniform finishing and extends the service life of abrasive belts and sisal brushes.

Efficient extraction system: Each group has dedicated extraction ports, connected to 8 x Ø 100 mm outlets, keeping the work area clean and efficient.

Quick side access: Large side openings allow easy brush change and rapid maintenance access.

Toothed belt transmission: Guarantees constant speed, stable drive, and low operating noise.

Finishing flexibility: The "fast release" system allows for quick changing of belts and brushes. Adaptable configuration suitable for various finishing styles and applications.

The DAS LDX 1000 – 6 is an efficient solution for manufacturers seeking superior quality in profiled wood processing, with high productivity and flawless finish.

Working width max.

1000 mm

Working height max.

100 mm

Longitudinal drum diameter (Ø)

220 mm

Longitudinal drum drive motor power – oscillating

2 x 1.5 kW

Oscillation motor power for longitudinal drums

0.55 kW

Ncsdpfxowhbtzs Abbjl

Oscillating pad diameter

200 mm

Oscillating pad drive motor power

1.5 kW

Oscillating pad oscillation motor power

0.18 kW

Transverse drum diameter (Ø)

280 mm

Transverse drum drive motor power

2 x 2.2 kW

Feed motor power

1.1 kW

Brush speed

max. 1000 rpm

Extraction port diameter (Ø)

4 x 100 mm

Overall dimensions

3300 x 1600 mm

Weight

1500 kg

Technical support available in Romanian, English or German.

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Ponudnik

Opomba: Brezplačno se registrirajte ali prijavite, za dostop do vseh informacij.

Registriran od: 2009

Pošlji zahtevo

Telefon & Faks

+40 756 3... oglasi

Ti oglasi bi vas prav tako lahko zanimali.

Mali oglas

Juszczyn

Juszczyn

530 km

Nagibna vretenasta rezkalnica

Panhans240A

Panhans240A

Mali oglas

Nattheim

Nattheim

457 km

CNC obdelovalni center

SCM morbidelliM 400

SCM morbidelliM 400

Mali oglas

Böblingen

Böblingen

533 km

Namizni rezkalni stroj

Holzkraftminimax t 45c Tischfräse

Holzkraftminimax t 45c Tischfräse

Mali oglas

Nemčija

Nemčija

650 km

Pločevinasta žaga

FELDERFORMAT 4 KAPPA 550

FELDERFORMAT 4 KAPPA 550

Mali oglas

Nattheim

Nattheim

457 km

Stoječa žaga za plošče

Putsch-MeniconiSVP 950 M ECO

Putsch-MeniconiSVP 950 M ECO

Mali oglas

Miechucino

Miechucino

937 km

Optimizator GreCon Dimter OPTICUT 350

WEINIGDimter Opticut 350 R

WEINIGDimter Opticut 350 R

Mali oglas

Egenhofen

Egenhofen

373 km

Stroj za krtačenje, stroj za brušenje

- ItalyAdvance ROTOR 600.4 / Special 5

- ItalyAdvance ROTOR 600.4 / Special 5

Mali oglas

Nattheim

Nattheim

457 km

Stena za odstranjevanje meglice barve

HöckerPaint Star 3500

HöckerPaint Star 3500

Mali oglas

Scerne

Scerne

397 km

Navpična žaga za plošče

Putsch MeniconiUniver

Putsch MeniconiUniver

Mali oglas

Askersund

Askersund

1.418 km

Pločevinasta žaga

SchellingFH 6 430

SchellingFH 6 430

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake