Univerzalni stružnica za kovinoCORMAK

TYTAN 750S

Univerzalni stružnica za kovino

CORMAK

TYTAN 750S

Stalna cena brez DDV

1.030 €

Leto izdelave

2025

Stanje

Novo

Lokacija

Siedlce

Prikaži slike

Prikaži karto

Podatki o stroju

- Opis stroja:

- Univerzalni stružnica za kovino

- Proizvajalec:

- CORMAK

- Model:

- TYTAN 750S

- Leto izdelave:

- 2025

- Stanje:

- novo

Cena in lokacija

Stalna cena brez DDV

1.030 €

- Lokacija:

- Brzeska 120, 08-110 Siedlce, Polska

Klic

Podrobnosti ponudbe

- ID ponudbe:

- A18854176

- Nazadnje posodobljeno:

- dne 07.01.2026

Opis

Precision metal lathe TYTAN 750S 230V with spindle speed control via DC inverter (frequency converter). Operating parameters: turning diameter 220 mm, turning length 750 mm, 1 kW motor at 230 V. The machine is designed for external and internal cylindrical surfaces, threading, drilling, countersinking, and reaming operations. Ideal for use in small manufacturing plants, workshops, or garages.

Machine Description

The TYTAN 750S 230V universal lathe, thanks to smooth spindle speed regulation, is ergonomic and meets user needs. Reduced setup time for machining parts of various sizes translates into higher efficiency and ease of operation.

S Version – electronic, stepless spindle speed control via DC motor and voltage regulator. This ensures high spindle chuck rotational accuracy, resulting in improved machining quality of workpieces.

Main advantages:

- Modern DC motor with stepless spindle speed adjustment ensures user comfort and shortens calibration time.

- LCD display with spindle speed readout for monitoring and quick spindle speed adjustment during setting of cutting and threading modes.

- Two spindle speed ranges: lower (50–1125 rpm) for machining hard steels and higher (100–2500 rpm) for high-speed precision turning.

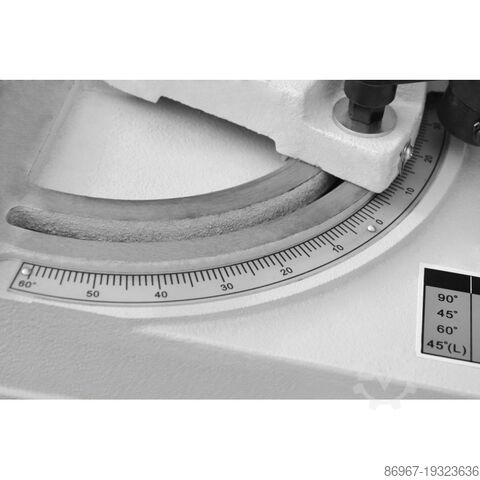

- Thread cutting – metric: 12 steps (0.4–3.5 mm), imperial: 12 steps (8–44 tpi), with capability to cut both left- and right-hand threads.

- Automatic feed – compliant with EU Directives (CE) and Polish standards (DIN).

- Fully compliant machine – easy and convenient to operate.

Machine stand available optionally

Technical specifications

Turning diameter over bed: 220 mm

Turning diameter over cross slide: 110 mm

Distance between centers: 750 mm

Bed width: 100 mm

Spindle bore: 38 mm

Spindle nose taper: MT5

Number of spindle speeds: stepless

Spindle speed range: 50–2500 rpm

Metric threading steps: 12

Metric thread range: 0.4~3.5 mm

Imperial threading steps: 12

Imperial thread range: 8–44 TPI

Longitudinal feed range: 0.15–0.25 mm/rev (2 steps)

Max compound slide travel: 70 mm

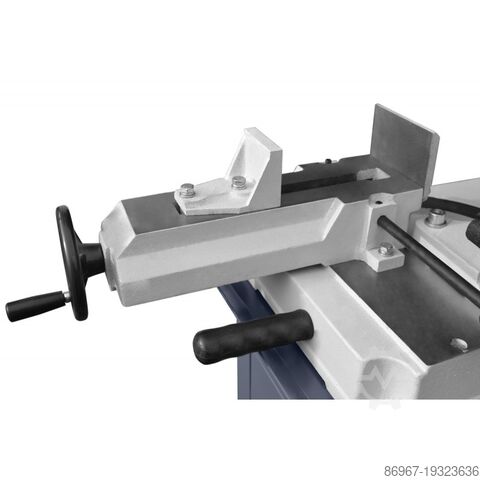

Max cross slide travel: 80 mm

Max carriage travel: 630 mm

Tailstock quill travel: 60 mm

Tailstock taper in spindle: MT2

Main motor: 1000 W

Tailstock sleeve feed distance: 60 mm

Tailstock sleeve taper: MT2

Main motor: 1000 W

Dimensions (L/W/H, without stand): 1250 x 380 x 1100 mm

Weight (without stand): 95 kg

Standard equipment

- 3-jaw chuck (125 mm)

Nedpfx Absv Uplasbscl

- Fixed and follow rest

- Change gears

- Fixed center MT2

- Fixed center MT4

- Oil gun

- Chip tray

- Chuck and tool post key

- Service tool kit

- Safety guards compliant with CE standards

- User manual in Polish

- CE declaration of conformity

Optional equipment

- Machine stand

- Set of 12 x 12 mm lathe tools (11 pcs with brazed inserts)

- Live center MT2

- Drill arbor MT2/B16

- HSS-CO5 cobalt drill set / 1–13 mm

- Universal coolant system

- ES-12 1L emulsion/cutting fluid

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Machine Description

The TYTAN 750S 230V universal lathe, thanks to smooth spindle speed regulation, is ergonomic and meets user needs. Reduced setup time for machining parts of various sizes translates into higher efficiency and ease of operation.

S Version – electronic, stepless spindle speed control via DC motor and voltage regulator. This ensures high spindle chuck rotational accuracy, resulting in improved machining quality of workpieces.

Main advantages:

- Modern DC motor with stepless spindle speed adjustment ensures user comfort and shortens calibration time.

- LCD display with spindle speed readout for monitoring and quick spindle speed adjustment during setting of cutting and threading modes.

- Two spindle speed ranges: lower (50–1125 rpm) for machining hard steels and higher (100–2500 rpm) for high-speed precision turning.

- Thread cutting – metric: 12 steps (0.4–3.5 mm), imperial: 12 steps (8–44 tpi), with capability to cut both left- and right-hand threads.

- Automatic feed – compliant with EU Directives (CE) and Polish standards (DIN).

- Fully compliant machine – easy and convenient to operate.

Machine stand available optionally

Technical specifications

Turning diameter over bed: 220 mm

Turning diameter over cross slide: 110 mm

Distance between centers: 750 mm

Bed width: 100 mm

Spindle bore: 38 mm

Spindle nose taper: MT5

Number of spindle speeds: stepless

Spindle speed range: 50–2500 rpm

Metric threading steps: 12

Metric thread range: 0.4~3.5 mm

Imperial threading steps: 12

Imperial thread range: 8–44 TPI

Longitudinal feed range: 0.15–0.25 mm/rev (2 steps)

Max compound slide travel: 70 mm

Max cross slide travel: 80 mm

Max carriage travel: 630 mm

Tailstock quill travel: 60 mm

Tailstock taper in spindle: MT2

Main motor: 1000 W

Tailstock sleeve feed distance: 60 mm

Tailstock sleeve taper: MT2

Main motor: 1000 W

Dimensions (L/W/H, without stand): 1250 x 380 x 1100 mm

Weight (without stand): 95 kg

Standard equipment

- 3-jaw chuck (125 mm)

Nedpfx Absv Uplasbscl

- Fixed and follow rest

- Change gears

- Fixed center MT2

- Fixed center MT4

- Oil gun

- Chip tray

- Chuck and tool post key

- Service tool kit

- Safety guards compliant with CE standards

- User manual in Polish

- CE declaration of conformity

Optional equipment

- Machine stand

- Set of 12 x 12 mm lathe tools (11 pcs with brazed inserts)

- Live center MT2

- Drill arbor MT2/B16

- HSS-CO5 cobalt drill set / 1–13 mm

- Universal coolant system

- ES-12 1L emulsion/cutting fluid

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Ponudnik

Opomba: Brezplačno se registrirajte ali prijavite, za dostop do vseh informacij.

Pošlji zahtevo

Telefon & Faks

+48 25 63... oglasi

Ti oglasi bi vas prav tako lahko zanimali.

Mali oglas

Lauda-Königshofen

Lauda-Königshofen

547 km

Udarni vijak

Morsoe

Morsoe

Mali oglas

Siedlce

Siedlce

853 km

Tračna žaga

CORMAKBS-128HDRC 400V

CORMAKBS-128HDRC 400V

Mali oglas

Feucht

Feucht

457 km

Center stružnica

OPTIMUMOPTIturn TZ 4 V

OPTIMUMOPTIturn TZ 4 V

Mali oglas

Gemmingen

Gemmingen

561 km

Stroj za brušenje cevi

NS MaquinasML 100

NS MaquinasML 100

Mali oglas

Velen

Velen

867 km

Rezalna in poševna žaga

HBM215 x 70

HBM215 x 70

Mali oglas

Rödermark

Rödermark

625 km

Motoriziran stroj za struženje palic

GLASERGDM 3-0 + GBR 666

GLASERGDM 3-0 + GBR 666

Mali oglas

Langenzenn

Langenzenn

487 km

Center stružnica

WEILERPrimus LZ

WEILERPrimus LZ

Mali oglas

Thalmässing

Thalmässing

433 km

Namizna stružnica

OptimumTU 2004 V

OptimumTU 2004 V

Mali oglas

Siedlce

Siedlce

853 km

Univerzalni stružnica za kovino

CORMAKTytan 750 PRO(400V)

CORMAKTytan 750 PRO(400V)

Mali oglas

Velen

Velen

867 km

Omare s predali

WMT136 / 9

WMT136 / 9

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake