Stroj za preoblikovanje cevi, obdelava koncev cevitransfluid Maschinenbau GmbH

UMR 642-CN

Stroj za preoblikovanje cevi, obdelava koncev cevi

transfluid Maschinenbau GmbH

UMR 642-CN

Leto izdelave

2025

Stanje

Novo

Lokacija

Schmallenberg

Prikaži slike

Prikaži karto

Podatki o stroju

Cena in lokacija

- Lokacija:

- Schmallenberg, Nemčija

Klic

Podrobnosti ponudbe

- ID ponudbe:

- A19563611

- Nazadnje posodobljeno:

- dne 16.07.2025

Opis

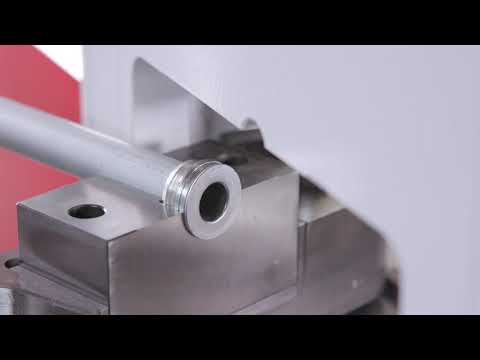

Tube Flaring Machine, Hydraulic Flaring Machine, Hydraulic End-Forming Machine, 37° Flaring Machine, 90° Flaring Machine, ORFS Flaring, JIC Flaring, Tube End Processing, Flaring Device, Tube Processing Machine, Rotary Forming Machine

Performance/Specifications:

- For tubes from 6 - 42 mm Ø

- Max. wall thickness 4 mm (at a tube diameter of 42 mm in steel)

- Cycle time (adjustable per forming process) 4 - 15 sec.

- RPM 200

Machine Equipment/Basic Configuration:

- For the end-forming of tube ends, e.g. angles between 37° and 90°

(tool-dependent) in a single rotary process

- Depending on the tube diameter, 180° bends with a minimum centerline dimension of 145 mm can be processed

- Clamping length depends on tube size, approx. 1.0 x D

- Forming length is limited by the tool geometry

- Operation and control via touch panel

- Activation via hand switch

- Feed of the tool carrier is hydraulic, feed speed adjustable

- Electrically adjustable length stop for determining tulip size

- Electrically adjustable forming stroke for setting tool advancement

- Electrically adjustable rolling duration

- Swiveling clamping jaw for easy insertion of ORFS rings

- Integrated drawer for tool storage

- Includes transparent safety covers for the working area

- Standard hydraulic and control components

- Stationary machine with base frame

- Color RAL 7047 grey, RAL 3020 red

Drives:

- Clamping of workpiece: servo-hydraulic

- Tool carrier feed: servo-hydraulic

- Tool carrier rotation: electric

Machine Data:

- Nominal pressure 250 bar, operating pressure 200 bar

- Operating voltage 400 Volt - 50 Hz - 3 Ph. - 4.5 kW

The machine's average energy consumption is approx. 1.8 kWh/h.

Nwjdpswzbc Nefx Abtop

As the consumption depends heavily on factors such as tube size,

geometry, speeds, and the machine’s power supply, this can only serve as a guideline.

- Length 1230 mm

- Width 710 mm

- Height 1240 mm

- Weight approx. 800 kg

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Performance/Specifications:

- For tubes from 6 - 42 mm Ø

- Max. wall thickness 4 mm (at a tube diameter of 42 mm in steel)

- Cycle time (adjustable per forming process) 4 - 15 sec.

- RPM 200

Machine Equipment/Basic Configuration:

- For the end-forming of tube ends, e.g. angles between 37° and 90°

(tool-dependent) in a single rotary process

- Depending on the tube diameter, 180° bends with a minimum centerline dimension of 145 mm can be processed

- Clamping length depends on tube size, approx. 1.0 x D

- Forming length is limited by the tool geometry

- Operation and control via touch panel

- Activation via hand switch

- Feed of the tool carrier is hydraulic, feed speed adjustable

- Electrically adjustable length stop for determining tulip size

- Electrically adjustable forming stroke for setting tool advancement

- Electrically adjustable rolling duration

- Swiveling clamping jaw for easy insertion of ORFS rings

- Integrated drawer for tool storage

- Includes transparent safety covers for the working area

- Standard hydraulic and control components

- Stationary machine with base frame

- Color RAL 7047 grey, RAL 3020 red

Drives:

- Clamping of workpiece: servo-hydraulic

- Tool carrier feed: servo-hydraulic

- Tool carrier rotation: electric

Machine Data:

- Nominal pressure 250 bar, operating pressure 200 bar

- Operating voltage 400 Volt - 50 Hz - 3 Ph. - 4.5 kW

The machine's average energy consumption is approx. 1.8 kWh/h.

Nwjdpswzbc Nefx Abtop

As the consumption depends heavily on factors such as tube size,

geometry, speeds, and the machine’s power supply, this can only serve as a guideline.

- Length 1230 mm

- Width 710 mm

- Height 1240 mm

- Weight approx. 800 kg

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Ponudnik

Opomba: Brezplačno se registrirajte ali prijavite, za dostop do vseh informacij.

Registriran od: 2024

Pošlji zahtevo

Telefon & Faks

+49 2972 ... oglasi

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake