Stiskalnica za betonHidralmac

150 Tonnen Betonpresse

Stiskalnica za beton

Hidralmac

150 Tonnen Betonpresse

Leto izdelave

2017

Stanje

Novo

Lokacija

Ennepetal

Prikaži slike

Prikaži karto

Podatki o stroju

- Opis stroja:

- Stiskalnica za beton

- Proizvajalec:

- Hidralmac

- Model:

- 150 Tonnen Betonpresse

- Serijska številka:

- DF0149

- Leto izdelave:

- 2017

- Stanje:

- novo

Cena in lokacija

- Lokacija:

- Scharpenberger Str. 96-98, 58256 Ennepetal, Deutschland

Klic

Podrobnosti ponudbe

- ID ponudbe:

- A3871212

- Št. reference:

- 1358-NEBR-1215

- Nazadnje posodobljeno:

- dne 27.03.2025

Opis

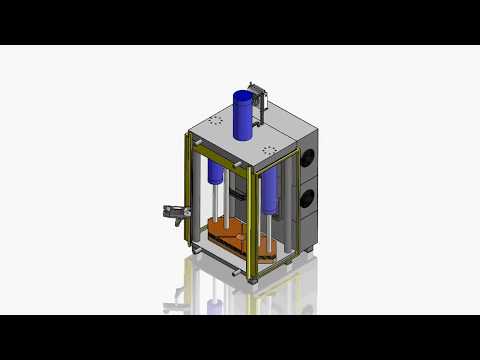

Pressure: 2x 75 / 150 t

Clear width: 2050 x 965 mm

Stroke: 800 mm

Total installed power: Main motor 22 kW

Approx. machine weight: 6.5 t

Required space approx.: 1500 x 1025 mm

Lower slide: 150 mm

Upper slide: 150 mm

Base plate steel: 72 mm

Additional motors and loads: 2 kW

Slide size upper slide approx.: 870 x 350 x 150 mm

Slide size lower slide approx.: 1500 x 600 x 150 mm

Base plate: 1500 x 1025 x 75 mm

Top plate: 1500 x 1025 x 150 mm

Guide pillar diameter: 120 mm

Piston diameter: 80 mm

Oil tank: 350 l

Oil requirement: 320 l

Stroke of both lift cylinders and pressure cylinder each: 350 mm

Max. open height: 1600 mm

Pressing speed: 15-0 mm/sec

Lifting speed: 100 mm/sec

Window size approx.: 2050 x 965 mm

Wall thickness approx.: 6 mm

Position control accuracy via non-contact sensors: 0.5 mm

The press is equipped with two column guides, each with a diameter of 120 mm, which guide both the lower and the upper slides. The guides are made of bronze.

The lower slide is designed to be extremely robust with a thickness of 150 mm. The upper slide also features a 150 mm thick steel plate.

Bwodpfx Afod Aftponsi

The base plate of the machine is made of 72 mm thick steel to ensure the machine can be safely transported. For this reason, the oil tank with the hydraulic system is also mounted close to the base.

Both the hydraulics and the electronics are permanently fixed to the machine and protected from contamination by a cabinet.

To dissipate the resulting heat, the machine is equipped with an oil cooler mounted on top of the press. The control cabinet is also air cooled.

For potential future maintenance work on the hydraulics, the interior rear panel of the press can be easily removed.

The two-hand control panel is permanently mounted to facilitate transport, but has a hinged joint for flexibility.

High-resolution light barriers prevent personnel from entering the danger zone.

For comfortable operation, the machine features transparent acrylic windows (6 mm thick) on both sides, which may need to be replaced after several years of use, though this is a minor expense.

Additionally, the press is equipped with 4 powerful LED lights integrated into the top plate.

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Clear width: 2050 x 965 mm

Stroke: 800 mm

Total installed power: Main motor 22 kW

Approx. machine weight: 6.5 t

Required space approx.: 1500 x 1025 mm

Lower slide: 150 mm

Upper slide: 150 mm

Base plate steel: 72 mm

Additional motors and loads: 2 kW

Slide size upper slide approx.: 870 x 350 x 150 mm

Slide size lower slide approx.: 1500 x 600 x 150 mm

Base plate: 1500 x 1025 x 75 mm

Top plate: 1500 x 1025 x 150 mm

Guide pillar diameter: 120 mm

Piston diameter: 80 mm

Oil tank: 350 l

Oil requirement: 320 l

Stroke of both lift cylinders and pressure cylinder each: 350 mm

Max. open height: 1600 mm

Pressing speed: 15-0 mm/sec

Lifting speed: 100 mm/sec

Window size approx.: 2050 x 965 mm

Wall thickness approx.: 6 mm

Position control accuracy via non-contact sensors: 0.5 mm

The press is equipped with two column guides, each with a diameter of 120 mm, which guide both the lower and the upper slides. The guides are made of bronze.

The lower slide is designed to be extremely robust with a thickness of 150 mm. The upper slide also features a 150 mm thick steel plate.

Bwodpfx Afod Aftponsi

The base plate of the machine is made of 72 mm thick steel to ensure the machine can be safely transported. For this reason, the oil tank with the hydraulic system is also mounted close to the base.

Both the hydraulics and the electronics are permanently fixed to the machine and protected from contamination by a cabinet.

To dissipate the resulting heat, the machine is equipped with an oil cooler mounted on top of the press. The control cabinet is also air cooled.

For potential future maintenance work on the hydraulics, the interior rear panel of the press can be easily removed.

The two-hand control panel is permanently mounted to facilitate transport, but has a hinged joint for flexibility.

High-resolution light barriers prevent personnel from entering the danger zone.

For comfortable operation, the machine features transparent acrylic windows (6 mm thick) on both sides, which may need to be replaced after several years of use, though this is a minor expense.

Additionally, the press is equipped with 4 powerful LED lights integrated into the top plate.

Oglas je bil preveden samodejno, zaradi česar je morda prišlo do napak pri prevodu.

Ponudnik

Opomba: Brezplačno se registrirajte ali prijavite, za dostop do vseh informacij.

Pošlji zahtevo

Telefon & Faks

+49 209 9... oglasi

Ti oglasi bi vas prav tako lahko zanimali.

Mali oglas

Italija

Italija

514 km

Popolnoma prenovljeno vroče radialno kovanje

CNC GFMSX-13

CNC GFMSX-13

Mali oglas

Oftersheim

Oftersheim

599 km

Hidravlična enota

Parker

Parker

Mali oglas

Nemčija

Nemčija

614 km

Cilindrični brusilni stroj - Universal

KIKINDAD15 - 2600/250

KIKINDAD15 - 2600/250

Mali oglas

Nemčija

Nemčija

650 km

Center CNC za struženje in rezkanje

Niles-SimmonsN30/2500 MC

Niles-SimmonsN30/2500 MC

Mali oglas

Hochdorf

Hochdorf

502 km

Enota za temperaturno hlajenje (TCU) / hladilnik

SingleChill Plus Testing CHT-130

SingleChill Plus Testing CHT-130

Mali oglas

Ciriè

Ciriè

583 km

Hidravlična stiskalnica z dvema stolpcema

EMANUELDEA 400/2000

EMANUELDEA 400/2000

Mali oglas

Fuldatal

Fuldatal

707 km

Ciklu pod nadzorom stružnica

Weisser HeinbronnHECKTOR CNC 295x2000

Weisser HeinbronnHECKTOR CNC 295x2000

Mali oglas

Neumarkt in der Oberpfalz

Neumarkt in der Oberpfalz

437 km

Gorilnik z dvojnim gorivom Weishaupt GL7-1750kW

Weishaupt GL7-1750kW Zweistoffbrenner1D-ZMD

Weishaupt GL7-1750kW Zweistoffbrenner1D-ZMD

Mali oglas

Mozé-sur-Louet

Mozé-sur-Louet

1.191 km

Stiskalnica

PromecamPPH25.12B

PromecamPPH25.12B

Mali oglas

Dellach

Dellach

159 km

Orodje brusilni stroj

Hispano SuizaAlbula

Hispano SuizaAlbula

Vaš oglas je bil uspešno izbrisan

Prišlo je do napake